Welding Tips

Nothing beats good training, excellent welding equipment, and constant practice when starting MIG welding. But you can also add a few professional MIG welding tips and tricks into the mix.

Stick Welding Tips & Tricks for Beginners

Welding can be a challenging skill to master, but with the proper techniques and precautions, you can achieve solid and clean welds. Here are some tips to help you improve your welding skills:

Safety First: Always prioritize safety. Wear appropriate personal protective equipment (PPE), such as welding gloves, a welding helmet with the proper shade lens, flame-resistant clothing, and steel-toed boots. Make sure your workspace is well-ventilated to avoid inhaling fumes.

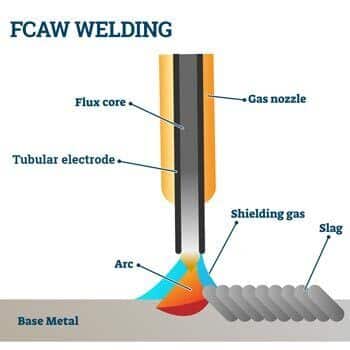

Choose the Right Welding Process: There are various welding processes like MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), Stick welding, and more. Choose the process suitable for the material you’re working with and the type of joint you need to create.

Clean Surfaces: Before welding, ensure the surfaces you’re joining are clean and free from rust, paint, oil, and other contaminants. Proper cleaning ensures a stronger and more consistent weld.

Correct Electrode/Wire and Polarity: If your process requires electrodes or wire, ensure you use the correct type for the welding material. Also, consider the correct polarity settings for your specific welding machine.

Good Fit-Up: Proper joint preparation and fit-up are essential for successful welding. Make sure the parts you’re welding are correctly aligned and have the correct gap (if needed) for your welding process.

Practice Proper Welding Techniques: Maintain a steady hand and move at a consistent pace. Avoid holding the electrode or torch too close or far from the workpiece. Experiment with different angles and travel speeds to find what works best for your application.

Controlled Heat Input: To avoid overheating the workpiece, which can lead to warping, distortion, or even burn-through, you can control the heat input by adjusting voltage, current, wire speed, or electrode amperage.

Tack Welding: Use tack welds to hold your workpieces in place before making the final welds. This helps prevent movement and misalignment during welding.

Welding Position: Different welding positions (flat, horizontal, vertical, overhead) require adjustments in technique and settings—practice in various positions to develop your skills.

Peening and Cleaning: Consider using a peening technique after welding. For certain types of welding, peening involves tapping the weld while it’s hot to relieve stress and improve strength. Additionally, clean the weld area of slag and spatter to ensure a neat appearance and optimal strength.

Quality Inspection: Regularly inspect your welds for cracks, porosity, or incomplete fusion defects. If you find any issues, address them before proceeding.

Keep Learning: Welding is a skill that takes time to master. Continuously learn from experienced welders, online resources, and tutorials. Don’t be afraid to ask for advice and seek feedback on your work.

Remember that practice is vital to becoming proficient at welding. Over time, you’ll better understand the best techniques for you and the materials you’re working with. Always prioritize safety and take your time to produce quality welds.