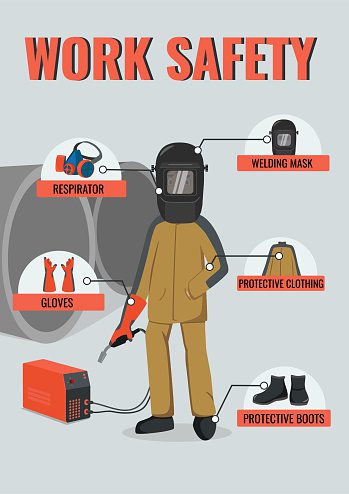

In the world of welding, safety is paramount. Therefore, it is crucial to equip oneself with the appropriate personal protective equipment (PPE) in order to safeguard against potential hazards. From head to toe, a welder’s attire should include a welding helmet with a face shield, protective safety glasses, a fire-resistant jacket or apron, heat-resistant gloves, sturdy steel-toed boots, and earplugs or earmuffs to protect against the deafening sound of intense welding. By donning this essential PPE, welders can confidently tackle their work, knowing that they are shielded from harm.

This image is property of www.anbusafety.com.

Head Protection

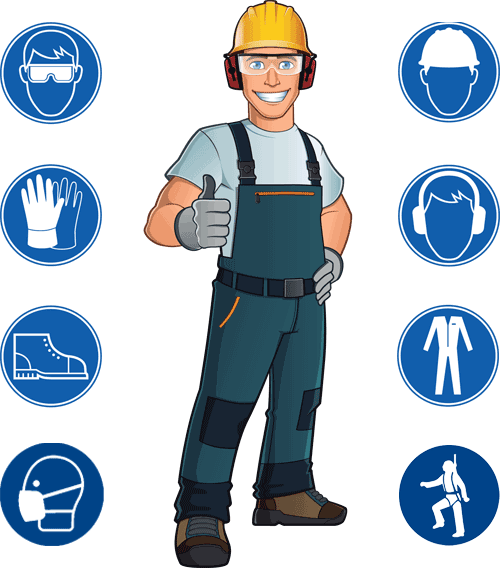

Hard Hats

Hard hats are essential for protecting our heads from falling objects and impacts. When working in welding environments, there is always a risk of materials or tools falling from heights. Hard hats provide a protective barrier against such hazards, reducing the risk of head injuries. They are made of a durable shell that can withstand impacts and distribute the force of the impact, minimizing the potential for serious head trauma.

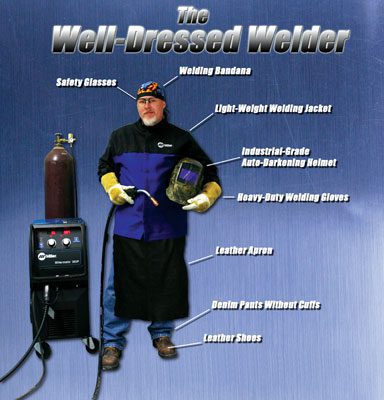

Welding Helmets

Welding helmets are specifically designed to protect our faces and eyes during welding operations. They feature a strong, heat-resistant material that shields us from the intense heat, sparks, and bright light generated during welding. In addition to the face shield, welding helmets also have a dark lens that automatically adjusts to the brightness of the welding arc, providing us with clear visibility while protecting our eyes from harmful ultraviolet (UV) and infrared (IR) radiation.

Welding Hoods

Welding hoods are another option for head protection in welding environments. They offer similar protection to welding helmets, with a heat-resistant face shield and a dark lens. However, welding hoods are typically lighter and less bulky than helmets, providing greater mobility and comfort. They are especially useful for tasks that require frequent removal of the headgear, as they can easily be flipped up or pulled back.

Eye and Face Protection

Safety Glasses

Safety glasses are a must for protecting our eyes from flying debris, sparks, and splashes. They provide a barrier against potentially harmful objects that could cause eye injuries. Safety glasses for welding purposes often have side shields to provide additional protection to the sides of our eyes. It is important to choose safety glasses that comply with industry standards and offer sufficient impact resistance, ensuring that they effectively shield our eyes from potential hazards.

Welding Goggles

Welding goggles are specifically designed to protect our eyes from the intense light, UV and IR radiation produced during welding. They cover a larger portion of our face than safety glasses, providing additional protection to the surrounding areas. Welding goggles are typically made of a heat-resistant material and feature dark lenses that protect our eyes from the harmful effects of the welding arc. They are an excellent choice for tasks that require close proximity to the welding operation.

Face Shields

Face shields offer comprehensive protection for the entire face, including the eyes, nose, and mouth. They are typically made of a transparent material, providing clear vision while shielding our face from flying debris, sparks, and splashes. Face shields are particularly useful in situations where there is a high risk of large-scale projectiles or a need for increased coverage. They can be used in addition to safety glasses or welding goggles for enhanced protection.

Welding Curtains

Welding curtains are an essential form of eye and face protection, especially in environments where multiple workers are engaged in welding tasks. These protective curtains are made of a fire-resistant material and are typically suspended around the welding area to create a physical barrier between the welding operation and other workers. Welding curtains help protect nearby individuals from the intense light, sparks, and hot particles generated during welding. They are an effective way to ensure the safety of everyone in the vicinity.

Respiratory Protection

Respirators

Respirators are vital for protecting our respiratory system from the harmful fumes, gases, and particles produced during welding. They come in various types, such as disposable filtering facepiece respirators (FFRs) and powered air-purifying respirators (PAPRs). Respirators for welding should have specific filters that can remove particles and fumes generated by the welding process. It is crucial to select a respirator that provides the appropriate level of protection against the specific hazards present in the welding environment.

Welding Fume Extractors

Welding fume extractors are specialized filtration systems that capture and remove hazardous fumes and particles from the air. These devices are particularly important in enclosed welding spaces or when ventilation is inadequate. Welding fume extractors consist of a fan and filters that capture and filter out the harmful contaminants, preventing their inhalation. They not only protect our respiratory system but also improve the overall air quality in the welding area, creating a safer work environment.

Hand and Arm Protection

Welding Gloves

Welding gloves play a crucial role in protecting our hands from burns, sparks, and sharp objects. They are made of flame-resistant materials that can withstand high temperatures and offer good dexterity and flexibility for handling welding equipment. Welding gloves should fit securely to provide optimum protection without compromising our ability to perform tasks accurately. They are an essential part of our personal protective equipment (PPE) when working with hot metals, sparks, and open flames.

Welding Gauntlets

Welding gauntlets are similar to welding gloves but offer extended protection to the forearms and wrists. They provide an extra layer of safety when working in close proximity to high heat sources or when there is a risk of molten metal splatter. Welding gauntlets are usually made of multiple layers of flame-resistant materials that effectively shield our hands, wrists, and lower arms from heat, sparks, and other welding-related hazards. They are especially beneficial when additional coverage is required.

Welding Sleeves

Welding sleeves offer specialized protection for our arms against heat, sparks, and UV radiation. They cover the forearms up to the elbows and are typically made of flame-resistant materials. Welding sleeves can be worn in combination with welding gloves or gauntlets for comprehensive arm protection. They are particularly useful when performing overhead welding or tasks that involve close contact with hot metal surfaces, providing an additional barrier against potential burns or injuries.

This image is property of www.millerwelds.com.

Body Protection

Welding Jackets

Welding jackets are designed to cover and protect our upper body, including the torso, shoulders, and arms. They are made of flame-resistant materials that can withstand high temperatures and protect us from sparks, spatter, and radiant heat. Welding jackets often feature additional reinforcements in high-wear areas, such as the elbows and shoulders, to enhance durability and longevity. They provide a vital layer of protection against heat-related injuries and burns during welding operations.

Welding Aprons

Welding aprons offer specialized protection for our lower body, specifically the waist, hips, and thighs. They are typically made of heavy-duty flame-resistant materials and provide an additional barrier against sparks, hot metal, and liquid splatters. Welding aprons are particularly useful when working in standing or kneeling positions, ensuring that our lower body remains well-protected. They are a practical and comfortable option for welders who need flexibility and freedom of movement while maintaining adequate safety.

Welding Bibs

Welding bibs are similar to welding aprons but are designed to protect the chest area. They provide an extra layer of safety against sparks, spatter, and intense heat. Welding bibs are typically made of the same flame-resistant materials as welding jackets and aprons. They can be worn alone or in combination with other protective garments, depending on the level of coverage required. Welding bibs are particularly beneficial when working in confined spaces or in close proximity to heat sources.

Welding Leggings

Welding leggings are specialized protective garments that shield our lower legs and feet from sparks, hot metal, and radiant heat. They are usually made of flame-resistant materials and provide an additional layer of safety when working in hazardous welding environments. Welding leggings offer excellent coverage for the calves and ankles and can be paired with welding boots for complete lower leg protection. They are especially useful when there is a risk of molten metal splatter or exposure to high heat sources.

Welding Pants

Welding pants are designed to cover and protect our entire lower body, including the legs and waist. They are made of flame-resistant materials and provide full-coverage protection against sparks, spatter, and radiant heat. Welding pants often feature reinforced areas at the knees and seat for enhanced durability and longevity. They offer a comfortable and practical solution for welders who require extensive lower body protection without sacrificing mobility and flexibility.

Foot and Leg Protection

Welding Boots

Welding boots are essential for protecting our feet from various welding-related hazards, such as sparks, hot metal, and falling objects. They are made of fire-resistant materials, providing a heat-resistant barrier between our feet and potential sources of heat. Welding boots often have reinforced toes and soles for added durability and protection. It is crucial to choose boots that fit well and have sufficient tread for slip resistance, ensuring that we have secure footing in the welding environment.

Welding Spats

Welding spats offer additional protection for our ankles and lower legs when wearing welding boots. They are typically made of flame-resistant materials and are worn over the lower part of the boots. Welding spats provide an extra layer of safety against sparks, hot metal, and radiant heat that may otherwise reach our legs through the gap between the boots and trousers. They are an excellent complement to welding boots for comprehensive foot and lower leg protection.

Welding Leg Guards

Welding leg guards, also known as shin guards, protect our lower legs from sparks, spatter, and other welding hazards. They are made of flame-resistant materials and cover the entire shin area. Welding leg guards are commonly worn in addition to welding pants or leggings to provide an extra barrier against potential injuries. They ensure that our lower legs remain well-protected, especially in situations where there is a high risk of molten metal splatter or exposure to intense heat.

Welding Chaps

Welding chaps offer specialized protection for our legs and thighs when working in welding environments. They are typically made of fire-resistant materials and are worn over regular work trousers. Welding chaps provide comprehensive coverage for the front of our legs and have adjustable straps for a secure fit. They effectively shield our lower body from sparks, hot metal, and radiant heat. Welding chaps are particularly useful when working in kneeling or crouching positions for extended periods.

This image is property of www.gowelders.com.

Hearing Protection

Ear Plugs

Ear plugs are a crucial form of hearing protection for welding environments. They help reduce the risk of noise-induced hearing loss by minimizing exposure to loud noises generated during welding operations. Ear plugs can effectively attenuate high-intensity sounds while still allowing us to hear necessary communication and warning signals. It is essential to choose ear plugs that fit properly and provide the required level of noise reduction to ensure optimal hearing protection.

Ear Muffs

Ear muffs offer an alternative form of hearing protection for welders. They cover the entire ear and provide a protective barrier against loud noises. Ear muffs can attenuate noise levels to a safer and more manageable range, reducing the risk of hearing damage. They are easy to put on and take off and can be quickly adjusted for optimal comfort. Ear muffs are particularly useful in environments with consistent high levels of noise, providing reliable hearing protection throughout the welding process.

Skin Protection

Welding Blankets

Welding blankets are essential for protecting surrounding surfaces and objects from sparks, spatter, and heat generated during welding operations. They are made of fire-resistant materials that can withstand high temperatures and prevent the spread of fires. Welding blankets can be used to cover and shield flammable materials, equipment, or nearby structures, reducing the risk of accidental fires or damage. They are an effective safety measure to maintain a controlled and safe welding environment.

Welding Tarpaulins

Welding tarpaulins function similarly to welding blankets and offer additional protection for larger areas. They are typically made of durable, fire-resistant materials and can cover a significant surface area. Welding tarpaulins are designed to prevent sparks, spatter, and heat from reaching nearby objects, machinery, or structures during welding operations. They are particularly useful in areas where there is a high risk of fire or when working on a project that requires extensive coverage.

This image is property of steelhub.files.wordpress.com.

Fall Protection

Harnesses

Harnesses are crucial for fall protection when working at heights or in elevated welding positions. They are designed to distribute the force of a fall across our body, reducing the risk of serious injuries. Welding harnesses typically include a full-body harness, adjustable straps, and various attachment points for connecting to safety lines or anchorages. They provide the necessary support and security needed when working in potentially dangerous locations, ensuring that we can perform welding tasks safely and confidently.

Safety Lines

Safety lines, also known as lifelines, are essential components of fall protection systems. They are attached to harnesses and secured to anchor points or structures capable of supporting the load of a fall. Safety lines provide a lifeline that can be used to arrest a fall, preventing us from hitting the ground or falling further. It is crucial to choose safety lines that are appropriate for the specific welding environment and comply with relevant safety standards. They are an integral part of a comprehensive fall protection system, allowing us to work at heights with peace of mind.

Emergency Eyewash and Showers

Emergency eyewash stations and showers are critical safety equipment in welding environments, providing a quick and effective way to flush contaminants from our eyes or skin in the event of an emergency. Accidental exposure to chemicals, fumes, or particles can occur during welding operations, and immediate decontamination is crucial to minimize potential injuries or long-term damage. Emergency eyewash stations are designed to deliver a continuous stream of clean water to flush our eyes, while showers provide a deluge of water to rinse our bodies. Properly maintained and easily accessible eyewash and shower facilities are vital in ensuring the safety and well-being of welders.

In conclusion, personal protective equipment (PPE) is essential for ensuring the safety and well-being of welders in various welding environments. Head protection, eye and face protection, respiratory protection, hand and arm protection, body protection, foot and leg protection, hearing protection, skin protection, fall protection, and emergency eyewash and showers are all crucial aspects of PPE for welding. By using the appropriate PPE, welders can significantly reduce the risk of injuries, burns, and other potential hazards associated with welding operations. It is essential for welders, employers, and safety professionals to understand the importance of PPE and adhere to the necessary safety protocols to create a safe and secure welding environment.

This image is property of cdn.shopify.com.