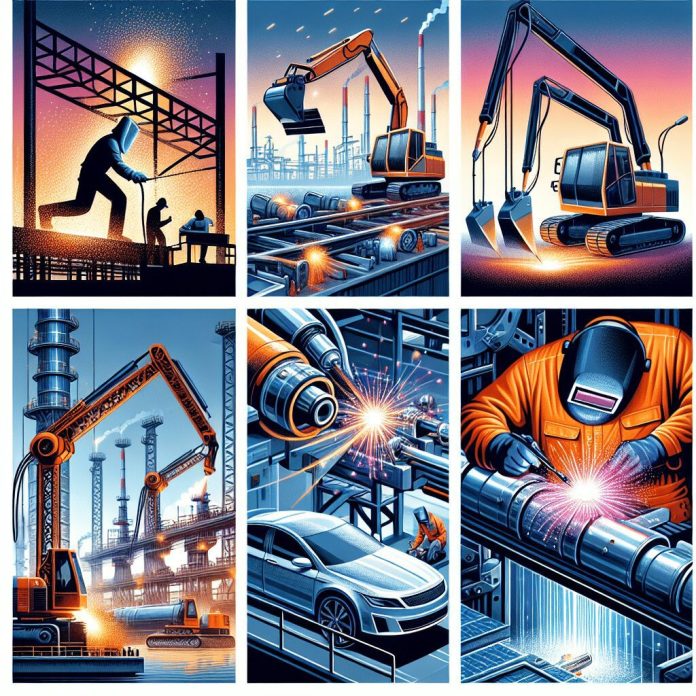

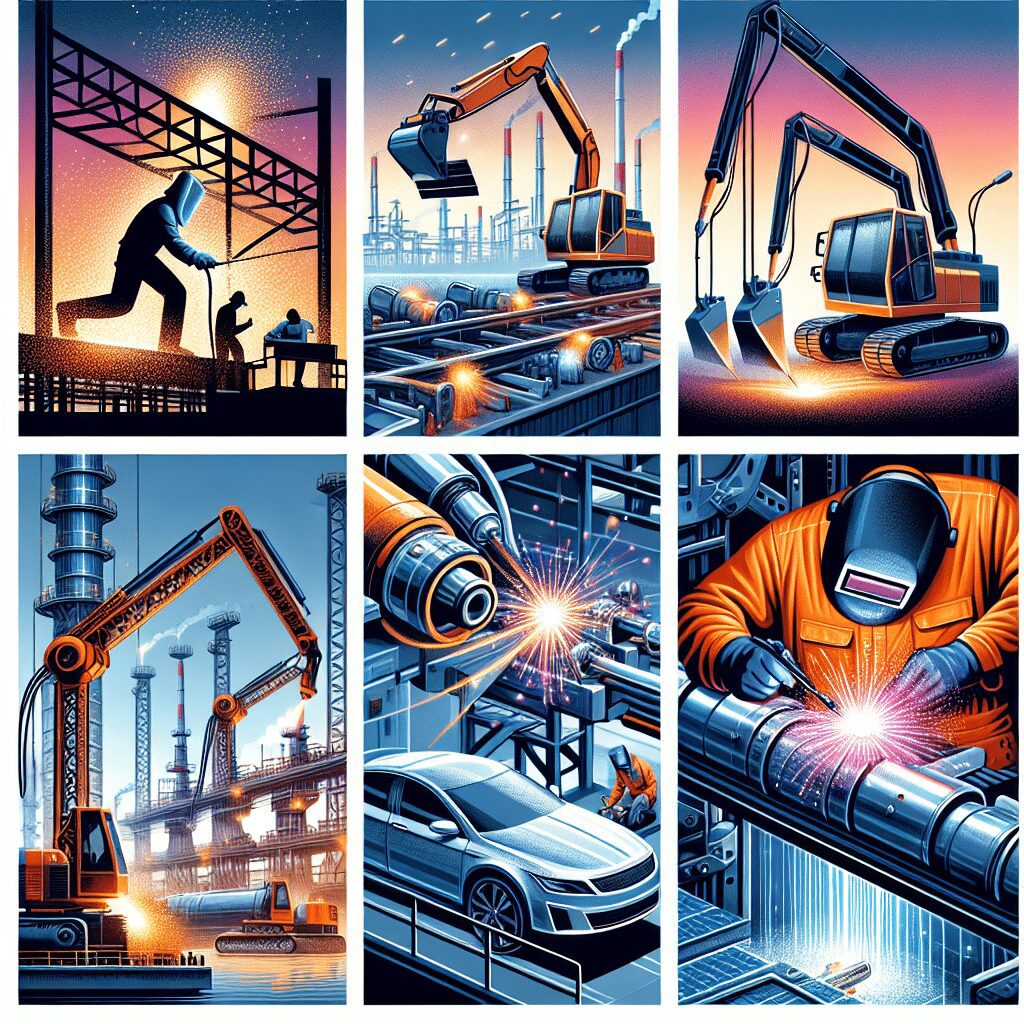

You may be surprised to learn that welding plays a significant role in a wide range of industries. From construction and manufacturing to automotive and aerospace, welding is a crucial technique used to join or repair metal components. The ability to fuse metal together with precision and durability has made welding an indispensable skill in industries that rely heavily on metal fabrication. In this article, we will explore some of the key industries that heavily rely on welding and delve into the reasons behind their high demand for this versatile process. So, let’s dive in and discover the fascinating world of welding in various industries.

Construction Industry

The construction industry is a vital sector of the economy, playing a crucial role in the development of residential, commercial, and infrastructure projects. From building homes to constructing bridges and tunnels, the construction industry encompasses various specialized fields that rely heavily on welding for their operations.

Residential Construction

Residential construction involves the construction, renovation, and remodeling of houses, apartments, and other residential structures. Welding is extensively used in this industry for various applications, including the fabrication of structural steel components, welding of metal roofing materials, installation of metal fences and railings, and joining of plumbing and HVAC systems. Welding ensures the durability, strength, and safety of residential structures, making it an indispensable part of the residential construction process.

Commercial Construction

Commercial construction involves the construction of non-residential buildings such as offices, retail spaces, hotels, and industrial facilities. Welding is critical in commercial construction for tasks like erecting steel frameworks, welding metal roof and wall cladding, joining HVAC and plumbing systems, and constructing metal stairs and railings. The high strength and stability provided by welding techniques are essential for the safety and functionality of commercial buildings.

Infrastructure Construction

Infrastructure construction refers to the development of large-scale public facilities, including roads, bridges, highways, tunnels, and pipelines. Welding plays a crucial role in infrastructure construction by joining metal components, reinforcing structures, and ensuring the integrity and longevity of these projects. From welding steel beams for bridges to connecting pipes in pipelines, the expertise of welders is indispensable in infrastructure construction.

Bridge Construction

Bridge construction involves building structures that span over rivers, valleys, or any physical barrier to facilitate transportation and connectivity. Welding plays a vital role in bridge construction as it is used to join various components, such as steel beams, plates, and cables. Welding techniques like arc welding, structural welding, and spot welding are employed to ensure the structural integrity, strength, and durability of the bridges, ensuring their safe and reliable operation.

Highway Construction

Highway construction involves the planning, design, and construction of road networks that connect cities, towns, and regions. Welding is widely used in highway construction for various applications, including the fabrication of guardrails, sign structures, lighting poles, and other metal components. Welding techniques like shielded metal arc welding (SMAW) and gas metal arc welding (GMAW) are employed to ensure the strength, stability, and longevity of these structures, keeping highways safe for motorists.

Tunnel Construction

Tunnel construction involves the excavation and construction of underground passages for various purposes, such as transportation, water supply, or mining operations. Welding is essential in tunnel construction for tasks like joining tunnel segments, reinforcing tunnel linings, and fabricating ventilation systems. Welding ensures the structural integrity of tunnels, providing stability and safety for people and equipment within these underground constructions.

Pipeline Construction

Pipeline construction involves the installation of pipes to transport fluids, gases, or other substances over long distances. Welding is a critical component of pipeline construction, as it is used to join pipe sections, fabricate fittings, and create secure connections. Various welding techniques, including shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW), and submerged arc welding (SAW), are employed to ensure leak-free and durable pipelines, enabling the efficient and reliable transportation of resources.

Automotive Industry

The automotive industry is a vast sector encompassing the manufacturing, assembly, and repair of automobiles and related components. Welding plays a crucial role in various aspects of the automotive industry, ensuring the structural integrity, durability, and safety of vehicles.

Automobile Manufacturing

Automobile manufacturing involves the production of vehicles, including cars, trucks, and motorcycles, from raw materials to finished products. Welding is extensively used in automobile manufacturing for joining various metal components, such as body panels, frames, and engine parts. Techniques like spot welding, resistance welding, and laser welding are employed to create strong and reliable welds, ensuring the structural integrity and safety of vehicles.

Automotive Assembly

Automotive assembly refers to the process of bringing together various components and subsystems to create a complete vehicle. Welding is an integral part of automotive assembly, as it is used to join different parts, such as chassis components, exhaust systems, and fuel tanks. Welding techniques like robotic welding and automated welding processes enhance production efficiency and precision, resulting in high-quality and reliable automobiles.

Automotive Repair and Restoration

Automotive repair and restoration involve fixing and restoring vehicles that have been damaged or worn out. Welding plays a critical role in automotive repair, enabling repair technicians to weld new components, replace damaged sections, and restore the structural integrity of vehicles. Whether it’s repairing body panels, frame sections, or exhaust systems, welding techniques are employed to ensure the longevity and safety of repaired vehicles.

Auto Parts Manufacturing

Auto parts manufacturing involves the production of components that are used in the assembly and repair of vehicles. Welding is extensively utilized in auto parts manufacturing to fabricate various metal components, including engine parts, exhaust systems, suspension components, and fuel tanks. Welding techniques like MIG welding, TIG welding, and resistance welding are employed to create high-quality and precise welds, ensuring the functionality and reliability of auto parts.

Aerospace and Aviation Industry

The aerospace and aviation industry involves the manufacturing and maintenance of aircraft, spacecraft, and related components. Welding plays a critical role in this industry, providing the necessary strength, durability, and safety for aerospace and aviation applications.

Aircraft Manufacturing

Aircraft manufacturing involves the production of airplanes, helicopters, and other aircraft from raw materials to fully functional machines. Welding is extensively used in aircraft manufacturing for joining metal components, such as fuselage sections, wings, and engine parts. Specialized welding techniques, including electron beam welding and laser beam welding, are employed to ensure precise and high-quality welds, meeting the stringent safety and performance standards of the aerospace industry.

Aircraft Maintenance and Repair

Aircraft maintenance and repair involve inspecting, repairing, and restoring aircraft to ensure their safe operation and longevity. Welding is a critical component of aircraft maintenance and repair, enabling technicians to weld new components, repair damaged sections, and reinforce structures. Welding plays a crucial role in tasks such as repairing aluminum skins, reinforcing structural components, and fabricating customized brackets or fittings to meet specific repair requirements.

Spacecraft Manufacturing

Spacecraft manufacturing involves the construction of vehicles designed for space travel and exploration. Welding is a vital part of spacecraft manufacturing, as it is used to join various metal components, such as spacecraft frames, fuel tanks, and propulsion systems. Welding techniques like gas tungsten arc welding (GTAW) and electron beam welding (EBW) are employed to ensure the structural integrity, reliability, and safety of spacecraft, allowing for successful space missions and exploration endeavors.

Rocket Manufacturing

Rocket manufacturing involves the production of rockets that are used for launching satellites, exploring space, and conducting scientific research. Welding is a critical process in rocket manufacturing, as it is used to join various metal components, including rocket bodies, engine nozzles, and propellant tanks. Specialized welding techniques, such as friction stir welding and laser welding, are employed to create strong and lightweight welds, ensuring the performance and safety of rockets during liftoff and space exploration missions.

Shipbuilding Industry

The shipbuilding industry involves the construction, repair, and maintenance of ships, boats, and other marine vessels. Welding plays a significant role in various aspects of shipbuilding, ensuring the structural integrity, stability, and durability of vessels.

Ship and Boat Manufacturing

Ship and boat manufacturing involve the construction of various types of vessels, ranging from small boats to large commercial ships. Welding is extensively used in ship and boat manufacturing for joining metal plates, constructing hulls, and fabricating structural components. Techniques like arc welding, gas metal arc welding (GMAW), and submerged arc welding (SAW) are employed to create strong and watertight welds, ensuring the reliability and safety of marine vessels during operation.

Ship Repair and Maintenance

Ship repair and maintenance involve the inspection, repair, and overhaul of ships to ensure their seaworthiness and prolong their operational lifespan. Welding is a critical component of ship repair and maintenance, enabling technicians to weld new sections, replace corroded or damaged parts, and reinforce ship structures. Welding techniques are used to repair hulls, propellers, deck components, and various other parts, ensuring the structural integrity and functionality of ships during their service at sea.

Marine Structure Fabrication

Marine structure fabrication involves the construction of various structures used in marine environments, such as offshore platforms, oil rigs, and marine terminals. Welding is an integral part of marine structure fabrication, as it is used to join large steel sections, create watertight connections, and ensure the structural integrity of these structures. Specialized welding techniques and materials are employed to withstand the harsh marine conditions, providing a durable and safe infrastructure for offshore activities and marine transportation.

Offshore Oil Rig Construction

Offshore oil rig construction involves the fabrication and installation of structures used for drilling oil and gas reserves located beneath the seabed. Welding plays a critical role in offshore oil rig construction, as it is used to join massive steel sections, create secure connections, and withstand the harsh offshore environment. Welding techniques like submerged arc welding (SAW) and shielded metal arc welding (SMAW) are employed to ensure the structural integrity and stability of offshore oil rigs, enabling safe and efficient offshore drilling operations.

Oil and Gas Industry

The oil and gas industry is involved in the exploration, production, refinement, and distribution of petroleum products and natural gas. Welding is widely utilized in the oil and gas industry for various applications, ensuring the integrity, safety, and reliability of the infrastructure used in these operations.

Oil and Gas Pipelines

Oil and gas pipelines are used to transport crude oil, natural gas, and various petroleum products over long distances. Welding is a critical process in pipeline construction, as it is used to join pipe sections, fabricate fittings, and create secure connections. Specialized welding techniques, such as gas metal arc welding (GMAW) and shielded metal arc welding (SMAW), are employed to ensure strong and leak-free welds, enabling the efficient and safe transportation of oil and gas resources.

Oil Refineries

Oil refineries are complex facilities that process crude oil into various refined petroleum products, such as gasoline, diesel, and jet fuel. Welding plays a crucial role in oil refineries for constructing and maintaining the infrastructure required for refining processes. From welding storage tanks and pressure vessels to joining piping systems and fabricating heat exchangers, welding ensures the integrity, safety, and functionality of oil refineries, allowing for the efficient production and distribution of petroleum products.

Gas Processing Facilities

Gas processing facilities are used to separate impurities from natural gas and convert it into a marketable product. Welding is an essential process in gas processing facilities for constructing the infrastructure needed to process and transport natural gas. Welding techniques are employed to join gas pipelines, fabricate gas storage tanks, and create secure connections within the facility. The expertise of welders ensures the safety, reliability, and efficiency of gas processing operations.

Liquefied Natural Gas (LNG) Plants

Liquefied natural gas (LNG) plants are facilities that cool natural gas to a liquid state for easier storage and transportation. Welding is critical in LNG plants for constructing the infrastructure required to handle and process liquefied natural gas. From welding LNG storage tanks and pipelines to joining cryogenic equipment and LNG carriers, welding ensures the safety, integrity, and efficiency of LNG plants, enabling the reliable production and global distribution of liquefied natural gas as an energy source.

Manufacturing Industry

The manufacturing industry involves the production of various goods and products, ranging from heavy machinery and appliances to furniture and tools. Welding is a fundamental process in the manufacturing industry, providing the necessary joining and fabrication capabilities for the production of high-quality and functional products.

Heavy Machinery Manufacturing

Heavy machinery manufacturing involves the production of large and robust machines used in various industries, such as construction, mining, and agriculture. Welding is extensively used in heavy machinery manufacturing for joining thick metal components, fabricating structural frames, and constructing durable machine parts. Welding techniques like shielded metal arc welding (SMAW) and flux-cored arc welding (FCAW) are employed to ensure the strength, stability, and functionality of heavy machinery.

Metal Fabrication

Metal fabrication involves the cutting, bending, and assembling of metal components to create structures, machinery, and various products. Welding is a critical process in metal fabrication, as it is used to join metal parts, create structural connections, and ensure the integrity of fabricated products. From welding metal sheets and plates to joining complex assemblies, welding techniques are employed to produce high-quality and precise welds, meeting the requirements of metal fabrication projects.

Appliance Manufacturing

Appliance manufacturing involves the production of household and industrial appliances, such as refrigerators, washing machines, ovens, and air conditioners. Welding is an essential process in appliance manufacturing for joining metal components, fabricating appliance housing, and ensuring the structural integrity and functionality of appliances. Welding techniques like resistance spot welding and laser welding are prevalent in appliance manufacturing, enabling efficient production and ensuring the quality and safety of appliances.

Furniture Manufacturing

Furniture manufacturing involves the production of various types of furniture, including chairs, tables, sofas, and cabinets. Welding plays a significant role in furniture manufacturing, enabling the production of metal furniture pieces that are both aesthetically pleasing and structurally sound. From creating metal frames and joints to joining different materials together, welding techniques are employed to ensure the stability, strength, and durability of furniture, meeting the diverse requirements of different furniture styles and designs.

Tool and Equipment Manufacturing

Tool and equipment manufacturing involve the production of various tools and equipment used in different industries and applications. Welding is vital in tool and equipment manufacturing for joining metal components, creating tool handles, and fabricating precise and durable equipment parts. From welding cutting tools and drills to joining equipment structures and handles, welding techniques are employed to ensure the quality, functionality, and reliability of tools and equipment, enabling efficient and safe operations in different industries.

Energy and Power Generation Industry

The energy and power generation industry involves the production of energy from various sources, including fossil fuels, nuclear power, and renewable resources. Welding is a fundamental process in this industry, ensuring the safe and efficient operation of power plants and renewable energy projects.

Power Plant Construction

Power plant construction involves the building of facilities that generate electricity from different energy sources, such as coal, natural gas, or nuclear reactions. Welding is extensively used in power plant construction for various applications, including joining boiler pipes, fabricating pressure vessels, and constructing turbine components. Welding techniques like shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW), and submerged arc welding (SAW) are employed to provide the necessary strength, durability, and safety for power plant infrastructure.

Nuclear Power Plants

Nuclear power plants generate electricity through nuclear reactions, requiring the construction and maintenance of specialized infrastructure. Welding is crucial in nuclear power plants for joining metal components, constructing containment structures, and ensuring the integrity of critical systems. Specialized welding techniques and rigorous quality control measures are employed to meet the stringent safety standards and regulations of the nuclear industry, ensuring the secure operation of nuclear power plants.

Renewable Energy Projects

Renewable energy projects involve the production of energy from renewable sources like wind, solar, hydro, and biomass. Welding plays a significant role in renewable energy projects, enabling the fabrication and installation of infrastructure necessary for capturing and converting renewable energy. From manufacturing wind turbine components to constructing solar panel support structures, welding techniques are employed to ensure the stability, durability, and longevity of renewable energy systems, facilitating the transition to more sustainable energy sources.

Wind Turbine Manufacturing

Wind turbine manufacturing involves the fabrication and assembly of components used in wind power generation. Welding is extensively used in wind turbine manufacturing for joining tower sections, fabricating turbine blades, and constructing support structures. Shielded metal arc welding (SMAW), metal inert gas welding (MIG), and flux-cored arc welding (FCAW) are employed to create high-quality and reliable welds, ensuring the strength, stability, and performance of wind turbines in harnessing wind energy for electricity generation.

Solar Panel Manufacturing

Solar panel manufacturing involves the production of photovoltaic panels used for converting sunlight into electricity. Welding plays a crucial role in solar panel manufacturing for joining metal frames, connecting solar cells, and creating electrical connections. Different welding techniques, such as laser welding and soldering, are employed to ensure the efficient assembly, durability, and performance of solar panels, enabling the harnessing of solar energy to generate electricity.

Hydroelectric Power Plants

Hydroelectric power plants generate electricity by harnessing the energy of flowing or falling water. Welding is critical in hydroelectric power plants for constructing and maintaining various infrastructure components, such as dam structures, turbines, and penstocks. Welding techniques are employed to ensure the structural integrity, stability, and hydraulic efficiency of hydroelectric power plants, enabling the reliable generation of electricity from water resources.

Railway and Transportation Industry

The railway and transportation industry involves the manufacturing, construction, and maintenance of railway systems, transport equipment, and related infrastructure. Welding plays a significant role in this industry, ensuring the safety, reliability, and efficiency of railways and transportation systems.

Railway Manufacturing

Railway manufacturing involves the production of locomotives, rolling stock, and other components used in the railway industry. Welding is extensively used in railway manufacturing for joining steel frames, fabricating carriages, and constructing rail tracks. Techniques like arc welding, gas metal arc welding (GMAW), and submerged arc welding (SAW) are employed to create strong and durable welds, ensuring the structural integrity and safety of railway systems.

Railway Infrastructure

Railway infrastructure involves the construction and maintenance of tracks, signals, and other facilities required for railway operations. Welding is a crucial process in railway infrastructure, as it is used to join rail tracks, repair track components, and fabricate railway bridges and tunnels. Techniques like flash butt welding and thermite welding are employed to create seamless and reliable rail connections, ensuring the safe and efficient movement of trains.

Metro System Construction

Metro system construction involves the building of underground railway systems to provide urban transportation solutions. Welding plays a vital role in metro system construction, enabling the fabrication and installation of tunnel segments, station structures, and other infrastructure components. From welding track connections to joining tunnel linings, welding techniques ensure the integrity, safety, and functionality of metro systems, facilitating efficient and sustainable urban transportation.

Transportation Equipment Manufacturing

Transportation equipment manufacturing involves the production of vehicles and equipment used for various transportation purposes, such as buses, trams, and railway carriages. Welding is widely used in transportation equipment manufacturing for joining metal components, fabricating vehicle frames, and ensuring the structural integrity and safety of transportation systems. Techniques like spot welding, resistance welding, and robotic welding are employed to create strong and reliable welds, enabling the production of high-quality and efficient transportation equipment.

Fabrication and Welding Services Industry

The fabrication and welding services industry involves providing custom metal fabrication, structural steel fabrication, welding, and repair services to a broad range of industries. Welding is the backbone of this industry, enabling the creation and repair of various metal products and infrastructure components.

Custom Metal Fabrication

Custom metal fabrication involves the production of metal components, structures, and products according to specific customer requirements. Welding is a fundamental process in custom metal fabrication, as it is used to join metal parts, create structural connections, and fabricate customized pieces. From welding architectural structures and industrial equipment to fabricating specialized components for different industries, custom metal fabrication relies on welding expertise to ensure the precision, quality, and functionality of the fabricated products.

Structural Steel Fabrication

Structural steel fabrication involves the fabrication and assembly of structural steel components used in construction, infrastructure, and industrial projects. Welding is extensively used in structural steel fabrication for joining steel beams, plates, and other components to create rigid and load-bearing structures. Techniques like shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and flux-cored arc welding (FCAW) are employed to create strong and reliable welds, ensuring the structural integrity and safety of fabricated steel structures.

Welding and Repair Services

Welding and repair services involve the inspection, repair, and restoration of metal structures, machinery, and equipment. Welding is a critical component of welding and repair services, enabling technicians to fix broken or damaged parts, reinforce structures, and restore the functionality of metal components. Whether it’s repairing pipelines, welding broken machinery, or reinforcing structural members, welding techniques are employed to ensure the durability and safety of repaired or restored items.

Industrial Maintenance and Shutdown

Industrial maintenance and shutdown services involve the periodic inspection, maintenance, and repair of industrial facilities and equipment. Welding is a vital component of industrial maintenance and shutdown services, as it is used to repair or replace damaged or worn-out parts, reinforce critical structures, and ensure the reliability and safety of industrial operations. Welding expertise is essential in industrial maintenance, as it plays a critical role in extending the lifespan and maximizing the efficiency of industrial facilities and equipment.

Defense and Military Industry

The defense and military industry involves the production and procurement of equipment, weapons, and technology for defense purposes. Welding is extensively used in this industry, ensuring the strength, durability, and reliability of armored vehicles, ammunition, and military equipment.

Armored Vehicle Manufacturing

Armored vehicle manufacturing involves the production of military vehicles designed to withstand ballistic and explosive threats. Welding is critical in armored vehicle manufacturing for joining armor panels, fabricating vehicle bodies, and creating strong and secure connections. Specialized welding techniques and materials, such as ballistic welding and high-strength steel welding, are employed to create robust and resilient welds, ensuring the protection and safety of military personnel and equipment.

Ammunition Manufacturing

Ammunition manufacturing involves the production of various types of ammunition used in firearms and artillery. Welding plays a crucial role in ammunition manufacturing for joining metal cases, fabricating projectile components, and ensuring the integrity and reliability of ammunition. Welding techniques like resistance welding and laser welding are employed to create strong and consistent welds, ensuring the safety and effectiveness of ammunition during military operations.

Military Equipment Production

Military equipment production involves the manufacturing of various equipment and components used by the armed forces, including communication devices, protective gear, and military accessories. Welding is extensively used in military equipment production for joining metal components, fabricating structural frames, and creating specialized military equipment. Welding techniques cater to the diverse requirements of military equipment, ensuring the strength, durability, and functionality required by military personnel during their missions.

National Defense Projects

National defense projects involve the development and production of military infrastructure, weapon systems, and strategic facilities. Welding is a fundamental process in national defense projects, as it is used to construct and maintain critical structures, fabricate military-grade equipment, and ensure the security and reliability of defense systems. From welding components for missile defense systems to constructing naval vessels, welding techniques are employed to meet the demanding standards and requirements of national defense projects.