A welding electrode functions as a filler material that is supplied to the weld pool during the welding process. It can be coated or bare, depending on its design and the application. The coating helps protect the weld from contamination and can also add certain properties to the weld. Selecting the right electrode involves considering factors such as the type of metal being welded, the position of welding, and the environment in which the welding occurs.

When looking for a welding electrode, it is essential to pay attention to the electrode type, size, and coating. Some electrodes work better with specific metals or in particular conditions, so knowing the job requirements is key. We researched several electrodes to help you identify which ones are best suited for various welding tasks.

Best Welding Electrodes

We have researched and compiled a list of the best welding electrodes available. These products offer quality and performance, making them suitable for various welding applications. Let’s explore our top picks to help you find the right electrode for your needs.

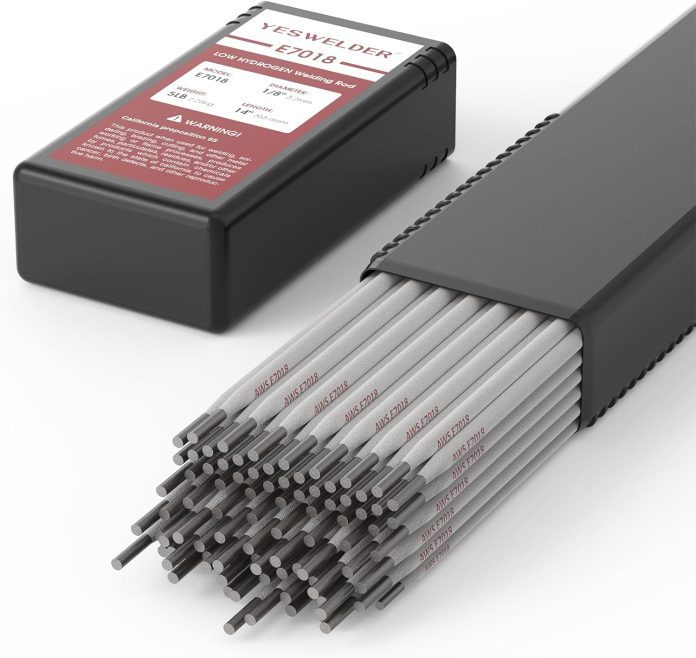

YESWELDER E7018 Welding Rods

We highly recommend these rods for reliable performance and excellent quality.

Pros

- Produces clean, strong welds with low spatter.

- Versatile for use with AC or DC machines in all positions.

- Moisture-resistant, offering good stability during the welding process.

Cons

- The packaging could be improved to ensure moisture protection.

- Requires proper storage to maintain rod quality over time.

- A few users reported issues with specific welder compatibility.

Using the YESWELDER E7018 electrodes has been a great experience for us. These rods work well with both AC and DC welding machines, making them a versatile choice for different projects. We found that they produce high-quality welds with minimal spatter, which is essential for a neat finish.

What we appreciated most was how easy it was to get a steady arc. This feature made re-striking the arc smooth and hassle-free. Whenever we needed to change positions or adjust our angle, we noticed that the rods maintained consistency, allowing us to focus on the quality of our work.

On the downside, we noticed that the packaging might not be the best at keeping moisture out. Proper storage is key to ensure the rods remain in good condition. A few people have mentioned compatibility issues with certain welders, so it’s important to check your equipment’s specifications. Overall, if you’re looking for reliable welding electrodes, the YESWELDER E7018 rods are worth trying.

Hobart 6013 Stick Welding Electrode

We found these electrodes to be a practical choice for various welding tasks.

Pros

- Works in all welding positions.

- High tensile strength of 60,000 PSI.

- Can run on different polarity settings.

Cons

- Packaging could be improved.

- Not ideal for heavy-duty jobs.

- Penetration might be less than expected.

Using the Hobart H117119-RDP 6013 welding electrodes, we appreciated how easy they were to use. Their ability to be applied in all positions made them versatile for multiple projects. We noticed they worked well with our stick welder, heating up nicely and creating good arcs.

The strength of these rods at 60,000 PSI was impressive for general tasks. While they excelled in lighter applications, we did feel they might struggle a bit under more demanding conditions. They produce a good weld, but if you’re working on thicker materials, you may want to consider a different option.

While we enjoyed using these electrodes, the packaging fell short. They arrived in a hard plastic shell, but it was a bit haphazardly put together. Overall, for routine weld jobs or smaller projects, these electrodes offer great value and reliability.

Blue Demon 7018 Electrode

We recommend this electrode for anyone looking to create strong, reliable welds, especially on carbon steels.

Pros

- Produces high-quality welds with low hydrogen content.

- Works well in various positions with both AC and DC.

- Good packaging to protect electrodes from moisture.

Cons

- Can be challenging to start for some users.

- May require practice to master the technique.

- Some inconsistency reported with certain welders.

We recently had the chance to use the Blue Demon E7018 electrode and were impressed with its performance. The low-hydrogen formula helps minimize defects in welds, making it a solid choice for working on medium-grade carbon steels. We felt confident using it in different positions.

The packaging was a nice touch, ensuring that the electrodes stayed dry and ready for use. We noticed the smooth arc and neat bead formation, which is a big plus for achieving clean welds. While we encountered some initial difficulty with starting the arc, it got easier with practice.

Overall, the Blue Demon E7018 performs well and is reasonably priced. For those looking to improve their welding skills, this electrode is a dependable addition to your toolkit.

WISUNO E6013 Welding Rods

We highly recommend these welding rods for their ease of use and solid performance across various welding tasks.

Pros

- Works well with both AC and DC machines.

- Easy to start an arc and maintain stability.

- Produces clean welds with minimal spatter.

Cons

- Limited to low carbon steel structures.

- May not perform as well with thicker materials.

- Some might find one pound packs too small for larger projects.

We have enjoyed using the WISUNO E6013 welding rods. They’re friendly for both beginners and experienced welders. The stable arc makes it simple to get started, which is a huge plus when working on different materials.

When we welded with these rods, the clean weld seams impressed us. They are easy to remove the slag afterwards, which saves time and effort in cleanup. We also liked how they came neatly packed in a plastic carrier. This thoughtful packaging makes storage and transport hassle-free.

These rods are particularly effective for low carbon steel structures. Whether we’re working on thin plates or needing a smooth finish, they deliver consistently. Although they may struggle with thicker materials, we found them to be reliable for most typical welding jobs.

For seasoned welders or those just starting, these welding rods are a valuable addition to our toolkit.

TOOLIOM E6013 Welding Rod

We think the TOOLIOM E6013 Welding Rod is a reliable choice for various welding tasks, especially for those who want solid performance without spending too much.

Pros

- Works well for general-purpose welding.

- Soft and stable arc, minimizing smoke and spatter.

- Ideal for welding thin materials and hard-to-reach spots.

Cons

- Packaging could be better for moisture protection.

- May not be suitable for heavy-duty applications.

- Some users wish for a wider range of sizes.

Using the TOOLIOM E6013 felt comfortable for our projects, especially when we tackled thin steel plates. The rods produced a clean weld without much fuss. We appreciated how the arc was stable and made it easy to manage, even for vertical welds. It felt like a nice balance of power and control.

Although the price was very reasonable, the packaging did raise a minor concern for us. While the rods performed well, we wished for a more airtight case to keep moisture away. Still, for typical tasks like working with thin metal or pipeline projects, these rods did the job perfectly.

In conclusion, the TOOLIOM E6013 Welding Rod stands out for its ease of use and effectiveness in various settings. If you’re in the market for reliable welding electrodes, this product is worth considering.

Buying Guide

When we buy welding electrodes, we want to consider several key features. These will help us choose the best options for our projects.

Types of Electrodes

There are different types of welding electrodes. Each type is suited for specific tasks. Common types include:

- MMA (Manual Metal Arc)

- TIG (Tungsten Inert Gas)

- MIG (Metal Inert Gas)

Diameter and Length

The diameter and length of the electrode matter. A thicker electrode is better for heavy materials. A thinner electrode is good for lighter tasks.

| Diameter | Best For |

|---|---|

| 1/16 inch | Thin materials |

| 1/8 inch | Medium work |

| 3/16 inch | Heavy-duty tasks |

Coating Type

The coating affects how the electrode performs. Some common coatings are:

- Cellulose: Good for outdoor work.

- Rutile: Provides a smooth finish.

- Basic: Strong arc stability.

Amperage and Voltage

We should match the electrode to our welding machine’s settings. Check the recommended amperage and voltage. Using the right settings ensures good penetration and bead quality.

Price and Quantity

Lastly, consider our budget. Electrodes come in various price ranges. Buying in bulk can save money. Compare prices based on type and quantity to find the best deal.

Here are some of the best welding electrodes to buy:

Lincoln Electric 1/8″ 7018 MR Welding Rods

Seven thousand eighteen rods are some of the most available electrodes in today’s world of welding. They can tackle repair projects, heavy pipe welding, and structural steel welding.

Since they are low hydrogen, they can just be exposed to air for a certain amount of time before they become faulty.

Jobs that need welding checks will need welders to keep their low hydrogen rods in a rod oven until they are used. This baking process will preserve the rods and their flux until they are ready to be burned.

Stick Electrode, 1/8 in. dia., 10 lb.

Lincoln Electric - K2939-1 Hydroguard Portable Electrode Oven| 10 lb Capacity | Premium Fiberglass Insulation | 115 V Only | K2932-1

Stick Elect, 7018 MR, 5/32 in, 14 L, 10 lb.

Read Next – What is the Best Pipe Welding Tools For You in 2024

Hobart 1/8″ 7018 Welding Rods

As much as we like Lincoln electrodes, Hobart provides more cost-friendly choices. These 7018 are comparable to the Lincolns, but they are not pretty as high-end.

We also noticed that the slag is harder to remove with these rods. The Lincolns slag pops right off, but these take pretty much work.

Considering the price difference, we think these rods are the best choice, mainly for starters. They burn truly perfectly, and they are just as powerful as Lincolns offering.

Hobart 770479 7018 Stick, 1/8-10lbs

Hobart 770474 7018Ac Stick, 1/8-5lbs

Hobart 770469 6013 Stick, 1/8-5 lbs.

Hobart 770465 7014 Stick, 1/8-10lbs

Read Next – Ideal Welding Tips – Tips to get the ideal weld

Forney 1/8″ 6010 Welding Rods

Six thousand ten are electrodes that can weld via just about any containment. They can power via rust, mill scale, oil, grease, etc. it is forever best to prep your metal, but 6010 can do even if you do not take the time to clean and grind your material.

These rods are primarily used for the root pass weld-on pipe joints. Because of these two varying uses, they come in handy for expert projects and nasty repair jobs.

They have more dig than low hydrogen rods, which permits them to penetrate via metals that are not clean.

Forney 30301 E6013 Welding Rod, 3/32-Inch, 1-Pound

$13.34 in stock

Forney 31101 E6011 Welding Rod, 3/32-Inch, 1-Pound

Forney 32101 E7014 Welding Rod, 1/8-Inch, 1-Pound

Forney 30805 7018 Welding Rod,1/8-Inch

Read Next – Best Welding Rods in 2024