Welding Machine

When it comes to welding, having a suitable machine is crucial. Whether you’re a professional welder or a DIY enthusiast, choosing the best welding machine can make all the difference in achieving high-quality and precise welds.

Knowing which suits your specific needs can be overwhelming with so many types of welding machines available on the market.

But fear not! In this comprehensive guide, we will break down the various types of welding machines and help you navigate the factors to consider when selecting.

From arc welding machines to MIG and TIG welders, spot welders to energy beam welding machines – we’ve got you covered!

So grab your safety gear, and let’s dive into the world of welding machines. By the end of this guide, you’ll have all the knowledge necessary to choose a welding machine that perfectly suits your requirements. Let’s get started!

Put your time into good use with a suitable machine for manual welding. Achieve process optimization and increased competitiveness once you choose to weld…

Welding machines – MIG/MAG – TIG – MMA

Welding machines, welding guns, or welders are essential tools for a welding professional.

Buying Your First Welder: A Practical, Informative Guide

Explore our selection of welding machines, including MIG welders, TIG welders, Stick welders, engine drive welder generators, submerged arc welders,

Understanding Different Types of Welding Machines

When choosing a suitable welding machine, it’s essential to understand the different types available and their specific applications. Here are some of the most common types of welding machines:

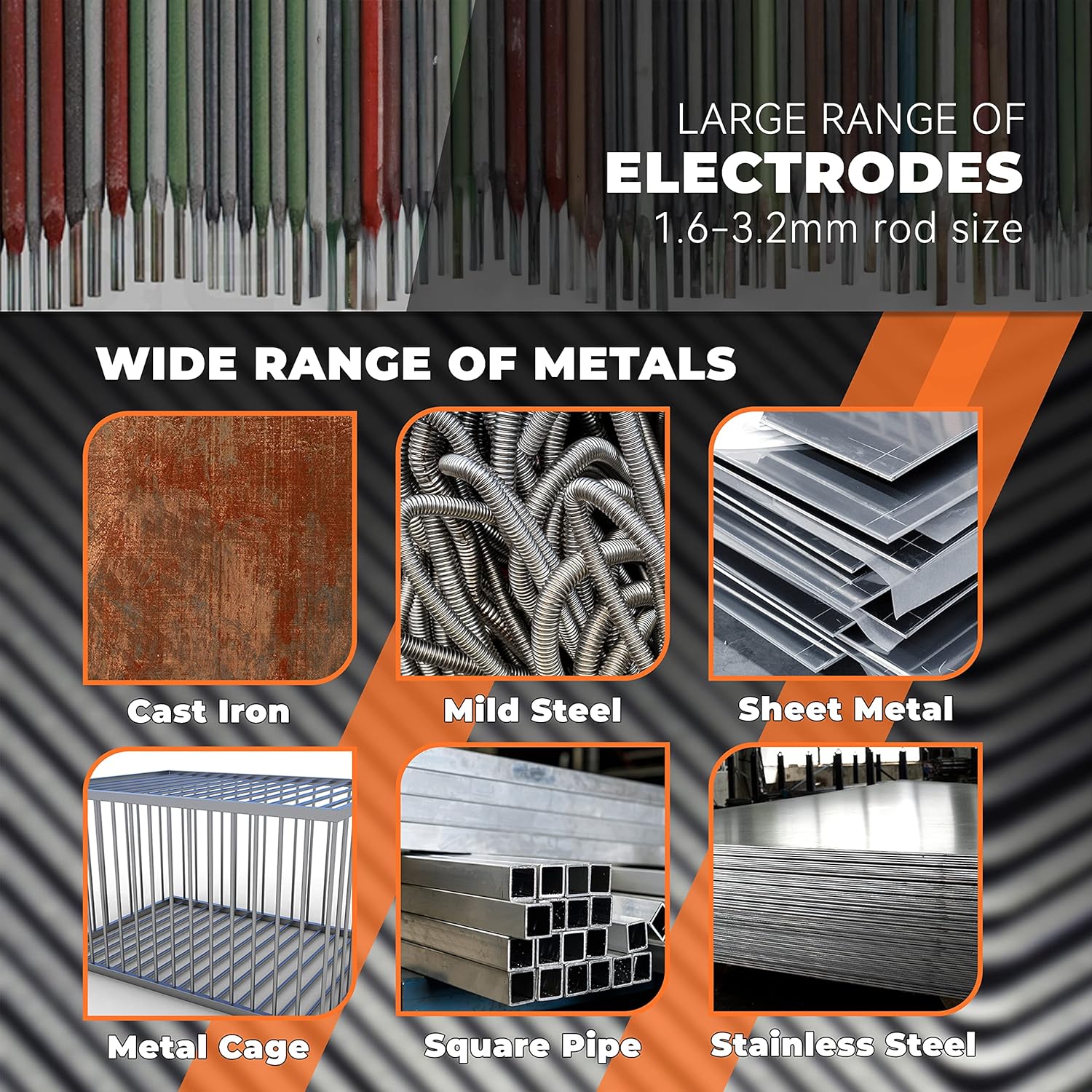

Arc Welding Machine: This machine uses an electric arc between an electrode and the workpiece to create a weld. It is commonly used for construction, repairs, and metal fabrication.

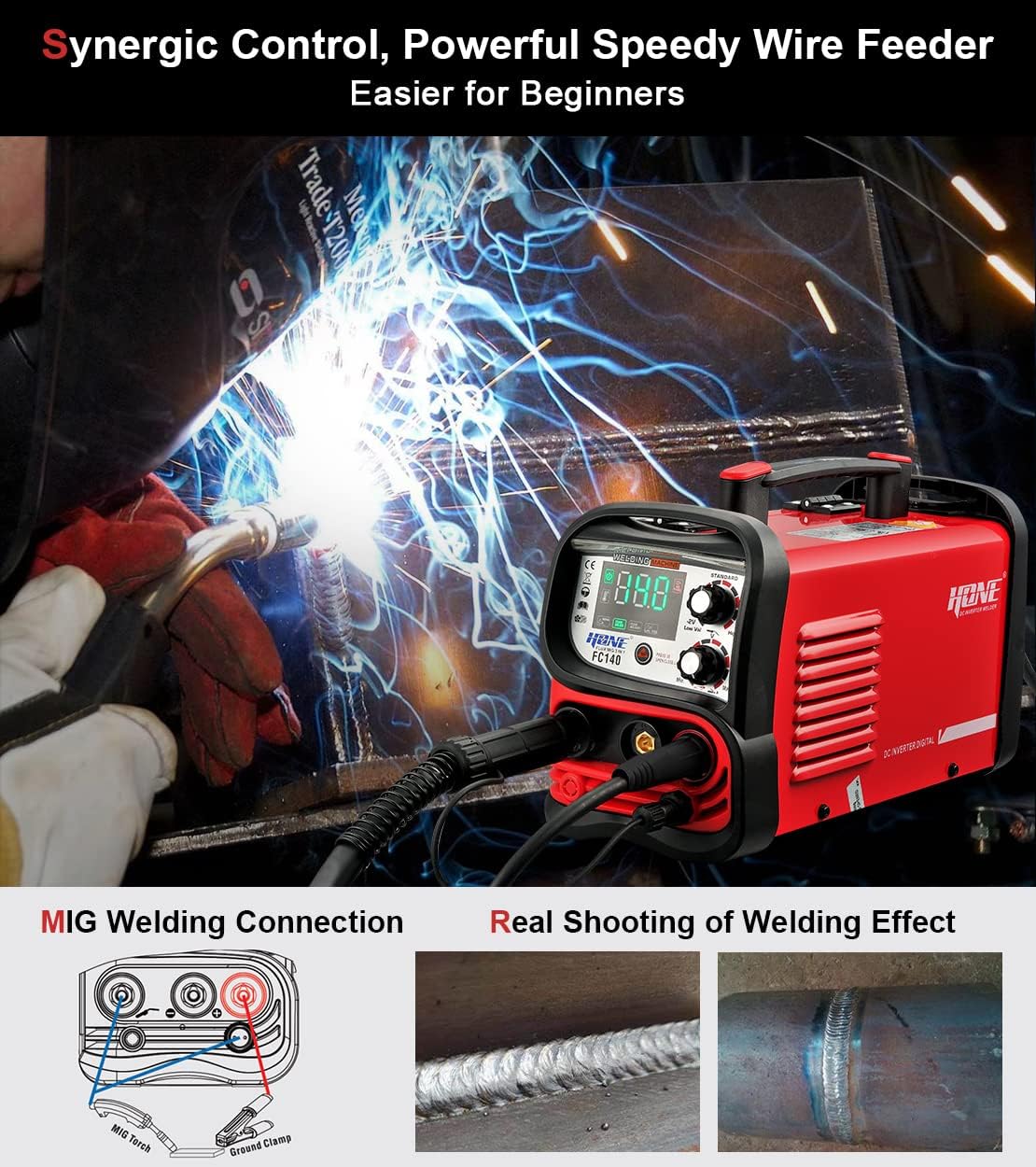

MIG Welding Machine: MIG stands for Metal Inert Gas, and this machine uses a continuous wire electrode that melts into the weld pool. It is famous for its versatility and ease of use.

TIG Welding Machine: TIG stands for Tungsten Inert Gas, and this machine uses a non-consumable tungsten electrode to create a precise and high-quality weld. It is often used in the aerospace industry.

Spot Welder: This machine creates welds by applying pressure and heat at specific points on metal sheets. It is commonly used in automotive manufacturing.

Oxyacetylene Welding Machine: This machine combines oxygen and acetylene gas to produce a flame that melts metal surfaces together. It is typically used in plumbing or jewelry making.

Thyristor MIG Welding Machine: This advanced version of MIG welding machines allows for better control over current flow, resulting in more precise welds.

Shielded Metal Arc (SMA) Welding Machine: Also known as stick welding, this machine uses an electrode coated with flux to create strong welds on iron or steel materials.

Energy Beam Welding Machine: Utilizing lasers or electron beams, this machine produces high-energy beams that melt metals together without physical contact.

Flux Core Arc (FCA)Welding Machine: Similar to MIG welding but without shielding gas, FCA machines have a tubular wire filled with flux that shields against oxidation during welding.

Atomic Hydrogen Welding Machine: This machine uses a stream of hydrogen gas that is heated and ionized to create a high-energy arc. It is used for joining complex materials such as tungsten and molybdenum.

Knowing the different types of welding machines can help you make the right choice for your project. Understanding their various features and applications can help you select the best machine.