Looking for a reliable solvent cement to bond acrylic that sets fast and holds strong?

Product Overview

I want to give you a thorough look at the IPS Weld-On 3 Acrylic Plastic Cement with Weld-On Applicator Bottle with Needle, 4 oz Can, Clear. I’ll cover what it contains, how it performs, how I use it, safety considerations, and how it compares to other options I’ve tried.

This product is a very fast-setting solvent cement designed specifically for bonding acrylic. I appreciate that it comes with an applicator bottle and needle, and the clear formula keeps finished work looking clean.

Quick Specifications Table

I find a table handy for a quick scan of core specs, so here’s a concise breakdown of the most important details. I use this as my checklist before starting projects.

| Feature | Details |

|---|---|

| Product Name | IPS Weld-On 3 Acrylic Plastic Cement with Weld-On Applicator Bottle with Needle, 4 oz Can, Clear |

| Type | Solvent cement (fast-setting) |

| Contents | 4 fl oz can + applicator bottle with needle |

| Color/Finish | Clear |

| Best For | Bonding acrylic (PMMA) |

| Application Method | Capillary action via applicator needle; can be applied with syringe or brush if transferred |

| Cure Time | Very fast initial set; full cure varies with joint size and conditions |

| Hazard Notes | Hazardous material; no air shipments (ground shipping only) |

| Typical Uses | Display cases, aquariums (with appropriate cure), light fixtures, acrylic fabrication |

IPS Weld-On 3 Acrylic Plastic Cement with Weld-On Applicator Bottle with Needle, 4 oz Can, Clear

$21.99 In Stock

What’s in the Box

I always check packaging carefully because the included tools can make or break the user experience. For this product, IPS provides a 4 oz can of Weld-On 3 and an applicator bottle with a needle that helps control the amount of solvent I apply.

I like that the applicator bottle with needle is included, since it saves time and reduces mess. The small needle tip allows precise, low-volume delivery directly into seams and capillary joints.

Packaging and Bottle

The applicator bottle is designed for precision and controlled flow. I find the needle useful for thin joints and for feeding solvent into the capillary gap without flooding the surface.

The bottle itself is squeezable and fits comfortably in my hand, which helps me steady my application. I sometimes transfer the solvent into the bottle and keep the original can sealed; this minimizes exposure and preserves the remaining solvent.

The Can

The 4 fl oz can is compact and easy to store in my workshop, but it also serves as the main reservoir to refill the applicator bottle. I always keep the can tightly sealed between uses to prevent evaporation and to maintain solvent strength.

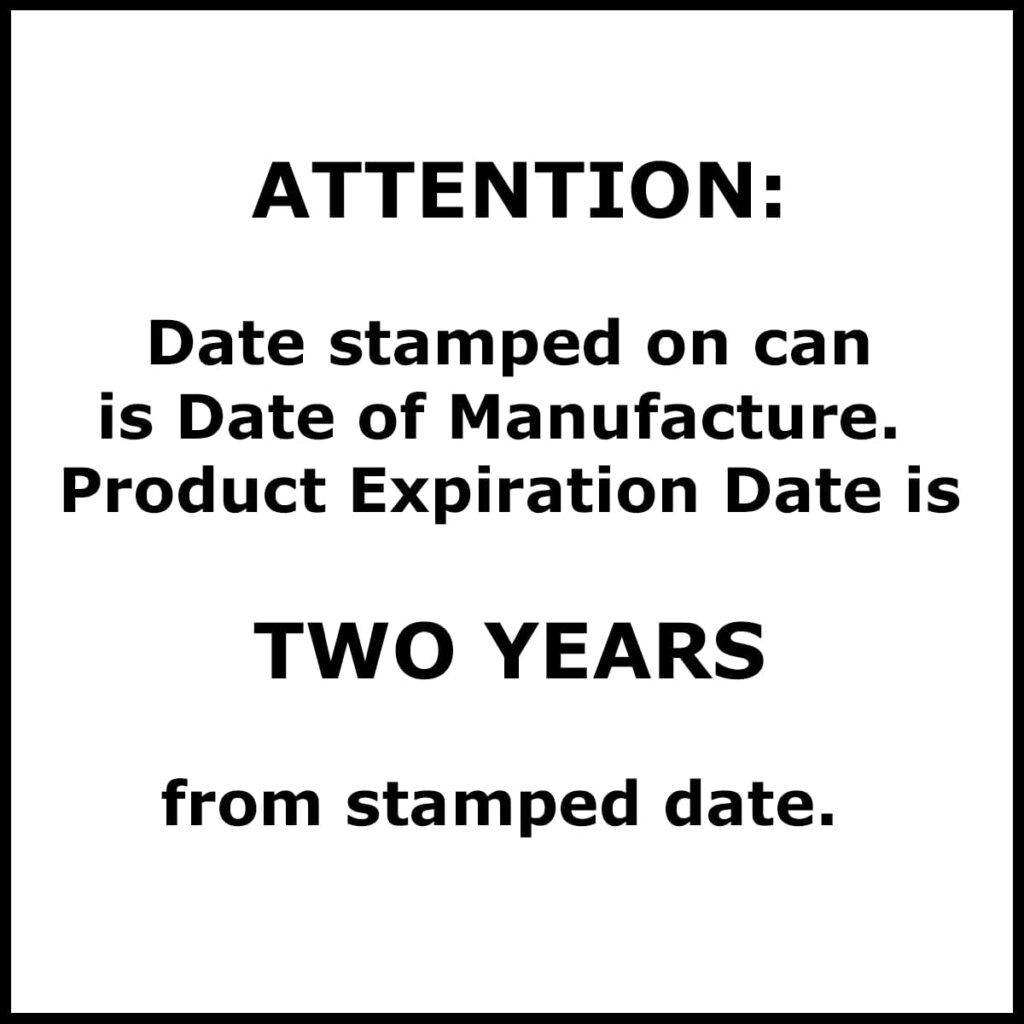

The can is labelled with hazard information and handling instructions, which I follow closely. Because this is a hazardous material, I make sure to store it out of reach of children and away from heat sources.

My First Impressions

When I first opened the can, the scent was sharp and unmistakable — typical of solvent cements. I was glad that the needle applicator allowed me to apply small amounts without overdoing it, which is important for clean joints.

The solvent’s consistency felt thin enough to flow by capillary action, but not so watery that it ran uncontrollably. That balance helped me achieve smooth joints with minimal finishing required.

Appearance and Smell

The liquid is clear and has a strong solvent odor that indicates its volatility and fast-setting properties. I always use it in a well-ventilated area because the fumes are potent and can irritate eyes and respiratory passages.

Because the solvent is clear, it doesn’t leave an obvious residue on acrylic surfaces if I use it correctly. However, I still avoid over-application to prevent surface crazing or visible marks.

Initial Handling

The applicator bottle and needle made my first application straightforward, especially for small display pieces and tight seams. I appreciated that I could squeeze slowly and see the capillary flow into the joint.

I took my time aligning pieces before applying solvent because Weld-On 3 grabs fast. I found that once the joint contacts, I had limited repositioning time.

Performance: Bond Strength and Setting Time

I tested the product on several acrylic thicknesses and configurations, and overall I found the bond strength to be robust for most non-structural to light-structural applications. The initial set was very fast, so I recommend preparing the joint thoroughly before applying solvent.

In my experience, the bond is visibly strong after initial set and gains additional strength over time as the solvent fully evaporates and molecular bonding completes.

Bonding Acrylic to Acrylic

Acrylic-to-acrylic joints bonded with Weld-On 3 formed neat seams that were both visually transparent and mechanically sound. I saw excellent capillary action in butt, lap, and miter joints when gaps were within recommended tolerances.

For critical applications, I make sure to design joints with adequate overlap or mechanical features, because while the solvent creates a strong bond, the geometry and thickness of the pieces impact final strength.

Working with Colored or Cast Acrylic

I tested clear cast acrylic and some colored extruded sheets, and the solvent behaved predictably on both. On colored acrylics, I paid attention to potential surface finish differences but generally achieved clean transitions if I used minimal solvent and wiped away any excess quickly.

I note that exotic or heavily filled acrylics might show surface effects more readily, so I recommend a test piece before committing to a final assembly.

Gaps and Surface Preparation

Weld-On 3 performs best on clean, flush surfaces with small capillary gaps; it is not a gap-filling adhesive. I always sand and clean mating surfaces to remove dust, oils, or machining marks that interfere with bonding.

If a gap is larger than a few thousandths of an inch, I use mechanical fasteners or a different adhesive designed for gap-filling first; otherwise the joint may be weaker or the solvent may not fully infiltrate.

Application: How I Use It

I have a routine now when I use Weld-On 3 that helps me avoid common mistakes. I set up clamps or jigs, mask surrounding surfaces with tape, and use the needle to apply solvent sparingly along the seam.

I find that working methodically and respecting the short working time produces the cleanest results.

Using the Weld-On Applicator Bottle with Needle

The needle makes capillary application simple and precise. I insert the needle tip into the seam and squeeze gently; the solvent is drawn into the joint and forms a micro-weld as the acrylic surfaces dissolve slightly and then fuse.

I keep a rag and solvent-resistant gloves handy to promptly clean any drips. If I need to refill the applicator bottle from the can, I do it carefully to avoid spills and keep both containers capped when not in immediate use.

Clamping and Alignment

Because Weld-On 3 sets quickly, I align and clamp pieces before applying solvent. I prefer using non-marring clamps or jigs to hold parts in position, which allows me to apply solvent without worrying about pieces shifting.

Once I release the clamp depends on joint geometry; for simple butt joints I generally wait about 10–30 minutes before light handling, and longer for full strength depending on thickness.

Avoiding Surface Crazing

Surface crazing (small cracks or whitening) can occur if the solvent is overapplied or pooled on the surface. I avoid this by using small amounts and allowing capillary action to draw the solvent into the joint rather than letting it sit on visible surfaces.

If I notice slight crazing, I stop, let it dry, and lightly polish the area. For deep crazing, I sometimes need to recut and re-bond the area, or use gentle heat and polish techniques if appropriate for the project.

Safety and Ventilation

I treat Weld-On 3 with respect because solvent cements contain volatile organic compounds (VOCs) that can be hazardous. I work in a ventilated area or under a fume hood and wear nitrile gloves and eye protection during application.

I always read the Material Safety Data Sheet (MSDS) and follow recommended precautions, including avoiding breathing fumes and keeping the product away from open flames or sparks.

Personal Protective Equipment (PPE)

I wear gloves, safety glasses, and in some cases a respirator with organic vapor cartridges when ventilation is limited. These precautions keep me safe and comfortable during prolonged use.

I also keep an easily accessible spill kit and fire extinguisher because the solvent is flammable. Proper PPE and emergency readiness are part of routine safety in my workshop.

Ventilation Tips

If I’m working indoors, I open windows and use a fan to move air away from my breathing zone. For frequent use, I set up a small local exhaust or fume extractor to capture vapors at the source.

I avoid prolonged exposure and take breaks to reduce inhalation risk. I also store the product in a cool, well-ventilated area to minimize evaporative buildup.

Drying, Curing, and Testing

Understanding the difference between initial set and full cure is crucial for safety and project planning. Weld-On 3 typically gives a fast initial set but may require hours or longer to reach full structural strength, depending on joint thickness and ambient conditions.

I always test a small sample joint or wait an appropriate cure time before putting a bonded assembly into service.

Initial Set and Handling Strength

I observed that initial handling strength can develop within minutes to an hour under ideal conditions. For thin acrylic and simple joints, I can handle the piece gently in a short time; for thicker sections or critical joints, I allow more time.

I avoid stressing the joint during this early phase because the solvent-bonded interface is still consolidating and may be weaker than expected.

Full Cure and Long-term Strength

Full cure depends on solvent evaporation and molecular re-bonding, which can take 24–72 hours or more for thicker assemblies. I schedule my projects to allow sufficient time for complete curing before placing heavy loads or subjecting parts to temperature cycles.

For permanent installations or aquarium use, I follow recommended cure times and, when in doubt, perform a controlled pressure or load test to validate the joint.

Compatibility and Limitations

I appreciate that Weld-On 3 is formulated specifically for acrylic (PMMA). That focus gives it excellent performance on intended materials, but I’m careful not to assume universal compatibility.

Knowing what the product works with and what it won’t bond helps me pick the right adhesive for the job.

Materials It Bonds To

This solvent cement works very well for acrylic-to-acrylic bonding. I have used it on both extruded and cast acrylic sheets with consistent results, and it produces bonds that are often as strong as the material itself when applied correctly.

I also use it for acrylic trims, small acrylic tubes, and acrylic components in light fixtures and display cases where solvent bonding is the preferred method.

Materials to Avoid

I avoid using Weld-On 3 on polycarbonate, ABS, PVC, or flexible plastics because the chemistry differs and the solvent will not create the same molecular bond. In some cases, solvent can damage or crazing other plastics.

For dissimilar materials, adhesives like epoxy, structural acrylic adhesives, or mechanical fasteners are often better choices. I also avoid using Weld-On 3 on painted or coated surfaces unless the coating is removed at the bond interface.

Shipping and Hazards

The product is classified as hazardous material and is not approved for air shipments. I learned this early on and plan purchases accordingly since ground delivery is required.

This shipping restriction is important for people who need the product quickly and might otherwise expect air shipping to be available.

No Air Shipments and Hazardous Material Notes

Because of flammability and VOC content, many carriers restrict air transport of products like Weld-On 3. I arrange for ground shipping and factor in delivery times when planning projects.

I also follow all local regulations and workplace rules for handling hazardous materials, including storage in a flammable cabinet if required.

Storage and Shelf Life

I store the sealed can in a cool, dry place away from direct sunlight and heat. I periodically check the can for signs of evaporation or crystallization, and I use the product within a recommended timeframe to ensure effectiveness.

If the solvent has thickened or changed color, I treat it as degraded and dispose of it per local hazardous waste guidelines.

Pros and Cons

I weigh the benefits and drawbacks of any tool or material I use, so here’s how I see Weld-On 3 after multiple projects.

Pros:

- Very fast-setting, which speeds up assembly.

- Clear finish that maintains the appearance of acrylic.

- Applicator bottle with needle included for precise application.

- Strong bonds on properly prepared acrylic surfaces.

Cons:

- Strong odor and hazardous vapors requiring ventilation.

- Not gap-filling; works best with close-fitting joints.

- Hazardous material restrictions (no air shipments) can delay delivery.

- Potential for surface crazing if overapplied.

I find that the pros outweigh the cons for typical acrylic fabrication tasks, provided I respect safety and application guidelines.

Alternatives I Considered

I’ve tried other adhesives in my shop for comparison, and they each have pros and cons depending on the project. I’ll summarize what I considered and why I usually return to Weld-On 3 for many acrylic tasks.

Other Solvent Cements (e.g., Weld-On 4, 16)

Alternative Weld-On formulations are available that vary in setting speed and viscosity. For example, Weld-On 4 is sometimes recommended for larger joints or when slightly slower set is desired, while Weld-On 16 may be better suited for thicker sections.

I choose the formulation based on joint size and required working time; for fast tacking and thin sheets, Weld-On 3 is my go-to.

Two-Part Acrylic Adhesives and Epoxies

Two-part structural adhesives or epoxies can fill gaps and bond dissimilar materials. I use those when I need gap-filling capability or when bonding acrylic to other substrates such as metal or glass.

While two-part adhesives offer versatility, they often require mixing, have curing schedules, and can leave visible seams. I prefer Weld-On 3 when aesthetics and optical clarity are priorities.

Cost and Value

I assess value not only by price but by performance and how much fuss is involved in achieving a good bond. In my experience, this product is competitively priced for a professional-grade acrylic solvent and the included applicator adds immediate value.

Because a little goes a long way, a 4 oz can lasts me a long time on small- to medium-scale projects, making the effective cost per use quite reasonable.

How Much I Use Per Project

My consumption depends on project size; for small displays or picture frames I may use only a few milliliters per joint. For larger fabrications, I budget accordingly and sometimes purchase multiple cans to have on hand.

I keep the applicator bottle dedicated to a specific formulation to avoid cross-contamination with other adhesives, which helps preserve the solvent’s effectiveness and reduces waste.

Long-term Cost Consideration

Over time, using a reliable product reduces rework and improves the quality of finished pieces. I consider that savings in repair time and improved aesthetics justifies the investment in a known, quality solvent like Weld-On 3.

If I needed to cost-compare for large production runs, I’d factor in labor savings from the fast set and lower finishing requirements.

Troubleshooting and Frequently Asked Questions

I’m often asked about common issues and how I solve them. Below are the problems I’ve encountered and the steps I took to fix or avoid them.

What if the Joint Shows Crazing?

Crazing usually results from overapplication or solvent pooling. I stop applying solvent, wipe away excess quickly with solvent-resistant rags, and let the area dry. For minor crazing, light sanding and polishing can help. For severe crazing, I sometimes disassemble and redo the joint.

I also modify my technique to use less solvent and rely more on capillary action to draw the solvent in rather than flooding the seam.

What If Parts Don’t Bond?

If the joint fails to bond, it may be due to surface contamination (oils, dust), improper fit, or incompatible acrylic. I clean both surfaces with isopropyl alcohol, ensure a tight fit, and test on scrap material. If those steps don’t work, I check the shelf life and storage conditions of the solvent.

For particularly problematic acrylic or heavily machined surfaces, I lightly abrade the interface with fine grit to create a fresh bonding surface.

How Do I Prevent Yellowing?

Acrylic itself can yellow under UV, and some adhesives can contribute if impurities are present. I use clear acrylic intended for optical clarity and avoid exposing finished assemblies to prolonged UV when possible. For display pieces, I sometimes use UV-stabilized acrylics and maintain minimal solvent on visible surfaces.

Routine polishing and keeping joints free of trapped solvent also reduce the risk of long-term discoloration.

Project Examples Where I Use It

I’ve used Weld-On 3 in a range of personal and professional projects. Sharing a few helps illustrate where the product shines.

- Display cases and museum mounts: I appreciate the optical clarity and neat seams for aesthetic presentations. I build jigs and use the needle applicator to ensure a clean capillary joint.

- Small aquaria and terraria: After following extended cure times and pressure testing, welded seams have held up well for small tanks. I always confirm manufacturer recommendations for aquarium use and ensure a complete cure.

- Lighting fixtures and diffusers: The clear, strong bond is ideal for assembling acrylic lenses and housings where seam visibility matters.

- Fabricated signage: For rigid, flat signs and overlays, the fast set minimizes downtime between assembly and installation.

I choose Weld-On 3 when a neat, near-invisible joint is important and when components are made entirely of acrylic.

Final Thoughts and Recommendation

After using IPS Weld-On 3 Acrylic Plastic Cement with Weld-On Applicator Bottle with Needle, 4 oz Can, Clear across several projects, I’m comfortable recommending it for anyone working primarily with acrylic. I value its fast setting time, clear finish, and included applicator that makes precision work easier.

I advise anyone using it to plan prep and clamping up front, follow safety practices diligently, and test on scrap material if you’re unsure about compatibility. If you need a strong, clean-looking bond for acrylic, this product is a reliable choice that I often reach for in my shop.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.