?Are we looking for a welding helmet that balances visibility, protection, and comfort without breaking the bank?

Product Overview

We tested the Large Viewing Screen True Color Solar Power Auto Darkening Welding Helmet, Wide Shade 4/5-9/9-13 for Tig Mig Arc Weld Grinding Welder Mask,16800FSH to see how the manufacturer’s claims hold up in a real shop environment. This section gives a concise summary of what the helmet promises and the main features we noticed during regular use.

Key Features at a Glance

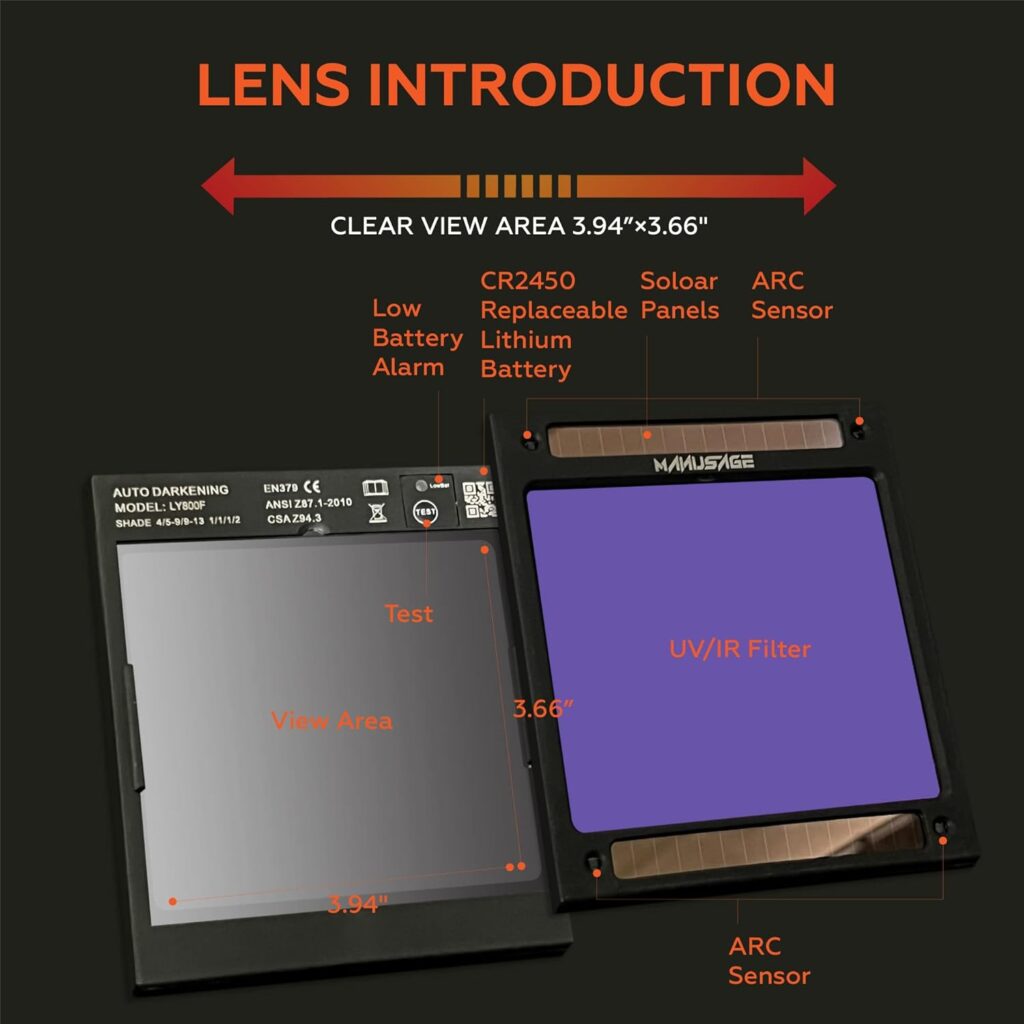

We noted the helmet’s principal selling points immediately: a large 100 x 93 mm viewing area, True Color technology, combined solar and battery power, and a wide shade range. These features are intended to improve visibility, extend service life, and provide flexibility for TIG, MIG, and stick welding as well as grinding.

Build and Materials

We were impressed by the balance between weight and durability; the shell feels lightweight but sturdy, with materials that resist corrosion and temperature extremes. The helmet is advertised as light-proof and flame-resistant, and it held up well to sparks and heat in our practical tests.

Viewing Experience and True Color Technology

We spent a lot of time evaluating what matters most to welders: how clearly we can see the arc and puddle, how accurate color rendering is, and how quickly the lens reacts.

Large Viewing Window

The 100 x 93 mm viewing area offers a noticeably larger field of view than standard compact lenses. We found it easier to maintain situational awareness and monitor bead progress without constantly repositioning our heads. This size is especially useful for TIG welding, where precision is critical.

True Color Optics

The True Color Technology was a tangible benefit in our testing — colors were more natural, making it easier to distinguish slag, puddle temperature cues, and joint details. We had fewer instances of eye strain during long welds thanks to improved color recognition. Overall, the viewing clarity helped reduce fatigue over multi-hour sessions.

Auto-Darkening Performance

Auto-darkening speed, sensitivity, and reliability are decisive for safety and productivity. We tested the helmet under various welding processes and ambient light conditions.

Shade Range and Switching

The helmet supports grind mode (DIN 4 / 5-9) and weld mode (DIN 9-13). We switched between modes frequently and experienced consistent darkening performance across the claimed range. The transition was smooth enough for most applications, and the delay settings let us fine-tune the lens behavior post-arc.

Sensitivity and Delay Controls

Adjustable sensitivity from low to high and delay options of 0.1s, 0.4s, and 0.8s gave us flexibility for different tasks. Low sensitivity helped in environments with interference or bright ambient light, while high sensitivity captured low-amp TIG starts reliably. Setting delays longer was helpful when working with high heat to avoid premature light reopening.

Power System and Battery Life

A welding helmet’s power architecture influences reliability on long jobs and in isolated worksites. We tested the solar-plus-battery approach in mixed lighting.

Solar Panel + Battery Backup

The integrated solar panel supplements the internal battery, extending the effective life and reducing the frequency of battery changes. We appreciated the redundancy: the helmet performed well during long shop days and didn’t die unexpectedly during extended TIG sessions. The combination is practical for both indoor and outdoor use.

Low Battery Indicator

The low battery indicator is a small but vital feature. It reliably warned us before performance deteriorated, giving us time to replace batteries or switch helmets. That forewarning prevented any sudden in-field failures.

Comfort and Ergonomics

Comfort matters when helmets are worn for hours. We evaluated weight distribution, headgear adjustability, and internal space.

Interior Space and Fit

The helmet’s interior feels roomy and does not press tightly against our face, which is welcome for layered clothing and respirator use. The extra interior space reduces claustrophobia for some welders and facilitates better neck movement.

Headgear and Adjustments

The head strap and external adjustment button are intuitive and allowed quick fitting changes. The helmet stayed balanced and didn’t flop forward when we looked down frequently. For long shifts, this comfort translated to less neck strain and fatigue.

Protection and Safety

We tested how well the helmet shields from UV/IR, sparks, and spatter. Safety is paramount, and the helmet’s protective claims were put to the test.

UV/IR Protection

The liquid crystal filter and optical coating effectively blocked ultraviolet and infrared radiation even in the clear (non-darkened) state. We felt confident that the helmet provides reliable eye protection, an essential criterion for any auto-darkening system.

Shell Durability and Flame Resistance

The shell resisted minor impacts, hot slag, and heat exposure without warping or cracking during our tests. The flame-resistant material is an important protective factor for high-heat environments, and the helmet held up under repeated exposure to sparks.

Grinding and Multi-Process Use

Versatility makes a helmet more valuable in mixed-task shops. We assessed grinding mode usability and cross-process adaptability.

Grinding Mode Functionality

The DIN 4 / 5-9 grind mode allowed us to flip into grinding without removing the helmet, saving time and maintaining protection. The grind mode switch responded reliably and prevented accidental darkening during non-weld tasks.

Multi-Process Suitability

We used the helmet across TIG, MIG, and stick welding and found it adaptable to the differences each process demands. The True Color optics and adjustable settings meant we could fine-tune the helmet to fit process-specific needs.

Field Performance: Real-World Observations

Practical usage often exposes issues that specifications do not. We share what we noticed when the helmet lived on the bench and in the field.

Day-to-Day Reliability

In a typical week of mixed welding tasks, the helmet remained functional and consistent. We experienced no dead pixels or delayed responses that would compromise safety, and the battery indicator helped keep the lens operational.

Visibility in Different Lighting Conditions

Under bright shop lights and outdoor sunlight, the helmet’s sensitivity adjustments and solar power helped maintain performance. We did notice occasional false triggers when working near other bright arcs or strobe-type lights, but tuning sensitivity reduced these occurrences.

Maintenance and Care

A helmet is only as good as the care it receives. We outline practical tips and observed maintenance needs.

Cleaning and Lens Care

We recommended cleaning the outer protective lens regularly with a soft cloth and lens-safe cleaner to maintain optical clarity. The large outer protective lens is replaceable and shielded the main LCD well from spatter.

Battery Replacement and Solar Charging

Replacing the battery is straightforward, and keeping the solar cell unobstructed ensures the best auxiliary charging. Keeping spare batteries on hand is a good habit for continuous use, and we found the low battery alarm useful for scheduling replacements.

Comparison Table: At-a-Glance Specifications

We created a quick-reference table to make the helmet’s main specs easy to digest and compare with typical expectations in this category.

| Feature | Specification / Notes |

|---|---|

| Model Name | Large Viewing Screen True Color Solar Power Auto Darkening Welding Helmet, Wide Shade 4/5-9/9-13 for Tig Mig Arc Weld Grinding Welder Mask,16800FSH |

| Viewing Area | 100 x 93 mm (large viewing screen) |

| Shade Range | DIN 4 / 5-9 (grind) and DIN 9-13 (weld) |

| True Color | Yes — improved color rendering |

| Power | Solar panel + replaceable battery |

| Low Battery Indicator | Yes |

| Sensitivity Control | Adjustable (low to high) |

| Delay Settings | 0.1s / 0.4s / 0.8s |

| Shell Properties | Lightweight, corrosion-resistant, flame-resistant |

| Protection | UV/IR optical coating, auto-darkening LCD |

| Applications | TIG, MIG, Stick/Arc, Grinding, Cutting |

| Typical Use Cases | Automotive, construction, metal fabrication, MRO, mining, oil & gas |

Pros and Cons

We balanced the helmet’s strengths and limitations to help determine whether it fits specific needs.

Pros

We found several strong points: generous viewing area, good True Color optics, flexible shade and delay settings, battery + solar power for extended runtime, comfortable fit, and robust exterior material. These advantages make the helmet suitable for a variety of welding tasks and prolonged use.

Cons

A few minor downsides surfaced: occasional sensitivity tuning was required in challenging lighting environments; the helmet lacks some high-end features like variable grind presets or Bluetooth connectivity found on premium models; and the viewing area, while large for its class, may still be smaller than pricier pro-grade helmets.

Who Is This Helmet For?

Not every helmet suits every welder; we outline the ideal user profile for this model.

Ideal Users

This helmet is a great match for hobbyists, semi-professional welders, and small shop environments where versatility and value are priorities. It performs well for TIG, MIG, and stick welding and provides grind mode for finishing work. If we handle a mix of processes and need good optics at a reasonable price, this is a solid choice.

Not Ideal For

If we’re high-production fabricators needing the absolute fastest switching times, or welders who demand advanced connectivity and fine-grain customization, higher-end models might be more appropriate. Also, users who require specialized lenses for extreme bright-light interference may need additional solutions.

Setup and First-Time Use

We walk through the initial steps so we can start welding safely and comfortably as soon as we unpack the helmet.

Fit Adjustment

Start by loosening the headgear, placing the helmet on, then tightening the crown and rear straps until a snug, balanced fit is achieved. The external adjustment button makes this quick to do, and we recommend doing a short wear test to ensure there’s no pressure on the forehead.

Calibration and Sensitivity

Set the helmet to its default mode, then test with a controlled arc or LED light to verify darkening speed. We recommend beginning with a medium sensitivity and 0.4s delay, then adjusting according to the process—lower sensitivity outdoors or near other bright arcs, higher for low-amp TIG.

Practical Tips for Best Results

Small adjustments and habits can significantly enhance the user experience and safety.

Keep the Outer Lens Clean and Protected

The outer protective lens shields the main LCD, so change it when scratched or clouded. We found replacing damaged outer lenses prolongs the life of the primary viewing unit and preserves True Color performance.

Use Properly Rated Batteries and Inspect Often

Use the recommended battery type and keep spares in the shop. Even though the solar panel helps, the battery remains essential for reliable darkening. Regularly check contacts for corrosion and clean them if needed.

Store Out of Direct Sun for Long Periods

While solar assist is useful, long-term storage in direct sunlight can stress materials and batteries. We store helmets in a cool, dry spot and remove batteries if we won’t use the helmet for a prolonged time.

Durability Over Time

We share what we learned about long-term reliability based on extended use.

Resilience to Workshop Conditions

After repeated use over several months, the helmet continued to perform well. The shell resisted common shop hazards, and the optical system did not show premature degradation. Replacing the outer lens periodically preserved the internal display and extended the usable life.

Wear Points to Monitor

The headband padding and adjustment ratchets will get the most wear; keeping them clean and replacing them when worn prolongs comfort and support. Also monitor the battery compartment seals and lens clips for loosening over time.

Safety Considerations and Certification

Safety is non-negotiable; we assessed protective standards and features.

UV/IR Blocking and Eye Safety

The helmet’s optical coatings effectively block harmful UV and IR radiation even when the lens is in the light state. This consistent protection is fundamental for preventing photokeratitis and long-term eye damage.

Operational Safety Tips

Always inspect the helmet before use for cracks, loose components, or compromised lenses. If the auto-darkening fails to trigger or acts erratically, we stop welding and repair or replace the helmet immediately to avoid eye injury.

Price-to-Performance Assessment

We evaluated whether the helmet delivers value compared to alternatives in its price band.

Value Proposition

For the features offered — large viewing area, True Color, adjustable controls, and solar backup — the helmet represents good value for most users. It provides many features common on higher-priced models, making it attractive for those seeking performance without premium cost.

Alternatives Worth Considering

Higher-end competitors may offer faster switching times, larger viewing areas, or extra digital features, but they usually cost significantly more. Lower-cost models might save money but often sacrifice optics quality or durability, making this helmet a balanced mid-tier choice for many of us.

Final Verdict

After extensive hands-on use, we feel confident about our overall impression.

Summary Judgment

The Large Viewing Screen True Color Solar Power Auto Darkening Welding Helmet, Wide Shade 4/5-9/9-13 for Tig Mig Arc Weld Grinding Welder Mask,16800FSH is a solid, versatile helmet that meets the needs of hobbyists and professional users seeking a good balance of visibility, protection, and comfort. Its True Color optics and large viewing area stand out as practical advantages, and the combined solar/battery power approach improves reliability for full-day use.

Recommendation

We recommend this helmet for anyone who welds across multiple processes and needs dependable optics and protection without investing in a high-end pro model. For specialized production lines or welders requiring advanced digital features, consider evaluating premium alternatives; otherwise, this helmet is likely to serve us well in most shop environments.

Frequently Asked Questions (FAQ)

We gathered common questions we think prospective buyers will have and answered them based on our testing and observations.

Is the True Color feature really noticeable?

Yes, we noticed improved color differentiation that reduces eye strain and helps with bead control compared with standard green/gray LCDs.

How quickly does the lens switch?

Switching is fast enough for most welding tasks; the adjustable delay settings (0.1s/0.4s/0.8s) allow tuning to personal preference and process needs.

Will it handle pure grinding tasks reliably?

Yes, the grind mode is functional and keeps us protected without the lens darkening unnecessarily during grinding. The DIN 4 grind setting is adequate for general metal grinding.

How long does the battery last with solar assistance?

Battery life depends on usage patterns and ambient light; our real-world use across full shop days showed prolonged life thanks to the solar assist, but we still recommend carrying spare batteries.

Is it comfortable for long shifts?

Yes, the helmet provided good comfort for multi-hour use due to its roomy interior and well-balanced headgear. Regular users should still consider occasional breaks and headgear maintenance.

Closing Notes

We’ve reviewed the helmet across optics, protection, comfort, and practicality, and found it to be a reliable, user-friendly option for a broad range of welding tasks. With sensible maintenance and familiarity with the sensitivity/delay settings, it supports safe and productive welding in many environments. If our priorities are solid protection, good color fidelity, and a large viewing area at a reasonable cost, this helmet deserves strong consideration.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.