In this article, we will explore the fascinating world of welding electrodes. These tools play a crucial role in the welding process, but understanding the various types and when to use them can be overwhelming. So, let’s break it down and demystify the world of welding electrodes, helping you gain clarity and confidence in your welding endeavors.

Electrode Basics

What is a welding electrode?

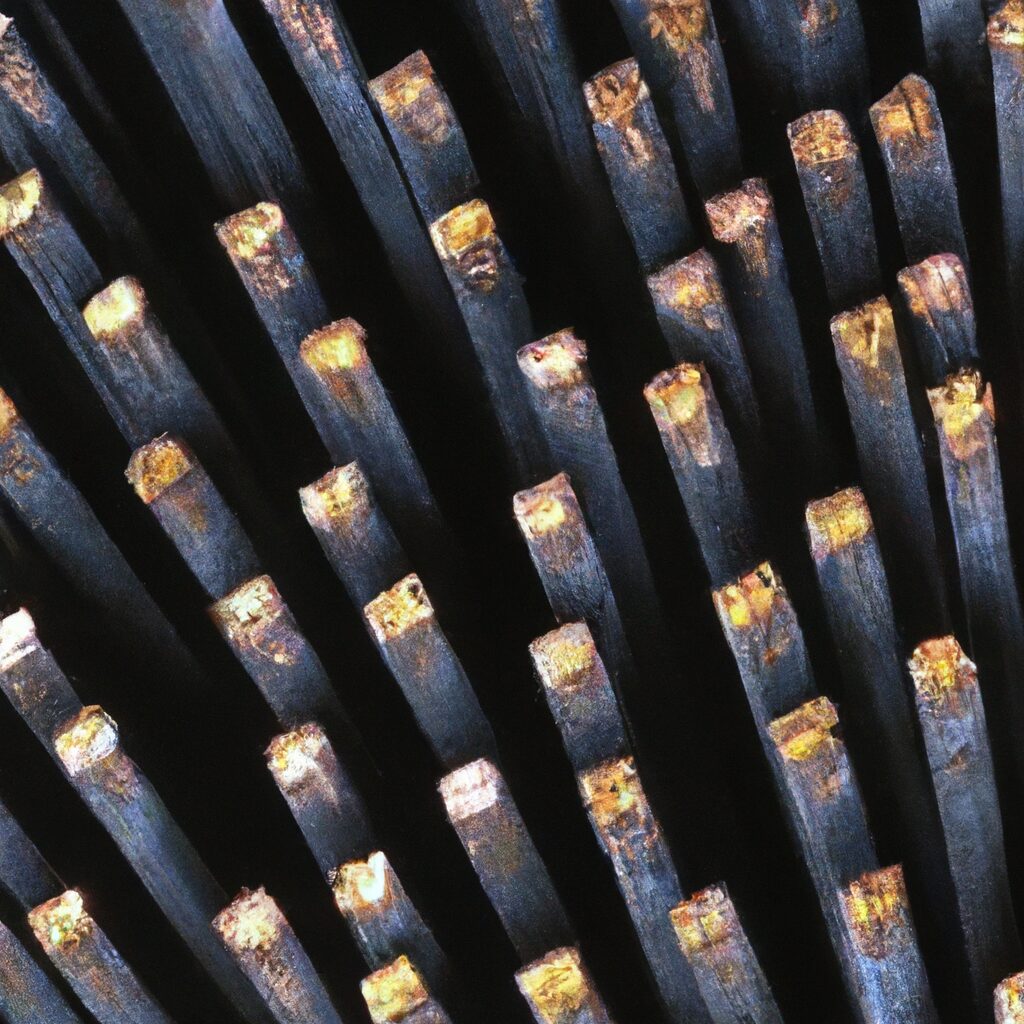

A welding electrode is a consumable metal rod or wire that plays a vital role in the welding process. It is used to conduct the electric current necessary to generate the heat required for welding. The electrode melts and forms a weld pool, which then solidifies to create a strong bond between two metal surfaces.

Types of welding electrodes

There are numerous types of welding electrodes available, each designed for specific applications and materials. The choice of electrode depends on factors such as the base metal, welding position, joint type, and desired mechanical properties. Electrodes can be classified based on their coating and composition, each fulfilling different requirements in welding processes.

Electrode classification based on coating

Welding electrodes can have different types of coatings, which serve multiple purposes during the welding process. Coatings can enhance the arc stability, control the molten metal transfer, improve the weld bead shape, and provide shielding gas protection. The most common electrode coatings include rutile, cellulosic, basic, iron powder, stainless steel, and aluminum.

Electrode classification based on composition

Electrodes can also be classified based on their composition, which determines their specific characteristics and applications. Different compositions are suitable for welding various base metals, such as mild steel, stainless steel, aluminum, cast iron, nickel alloys, copper alloys, titanium, and magnesium. The varying compositions ensure that the electrodes possess the necessary mechanical properties to create strong and durable welds.

Common Types of Welding Electrodes

1. Rutile electrodes

Rutile electrodes, also known as E6013 electrodes, are the most commonly used type of welding electrode. They have a rutile-based coating and are ideal for general-purpose welding applications. These electrodes provide good arc stability, easy arc initiation and re-striking capabilities, smooth weld beads, and minimal spattering. Rutile electrodes can be used on mild steel, stainless steel, and galvanized steel in various welding positions.

2. Cellulosic electrodes

Cellulosic electrodes, also referred to as E6010 and E6011 electrodes, are specifically designed for welding in challenging conditions. The cellulose-based coating on these electrodes produces a deep penetrating arc, allowing for welding in vertical and overhead positions with high current settings. Cellulosic electrodes are often used for pipe welding, shipbuilding, and structural steel fabrication.

3. Basic electrodes

Basic electrodes, or E7018 electrodes, are widely used for their excellent mechanical properties and high-quality welds. Due to their low hydrogen content, they provide superior crack resistance, making them suitable for applications in high-strength steels, low-alloy steels, and critical structures. Basic electrodes offer good penetration, easy slag removal, and efficient deposition rates.

4. Iron powder electrodes

Iron powder electrodes, such as E7014 electrodes, have high metal deposition rates, making them ideal for welding joints with thicker fillet or groove welds. The iron powder content in these electrodes enhances their productivity and results in higher efficiency and reduced slag. They are often used in heavy fabrication and structural welding, where high-quality welds with high deposition rates are desired.

5. Stainless steel electrodes

Stainless steel electrodes, also known as E308 and E316 electrodes, are specifically designed for welding stainless steel. These electrodes contain alloys that provide excellent corrosion resistance and mechanical properties. Stainless steel electrodes are commonly used in industries such as food processing, chemical, and pharmaceutical, where resistance to oxidation and contamination is crucial.

6. Aluminum electrodes

Aluminum electrodes, such as E4043 and E5356 electrodes, are used for welding aluminum and aluminum alloys. These electrodes have a high melting point and good fluidity, ensuring efficient penetration and fusion. Aluminum electrodes are commonly employed in industries like aerospace, automotive, and marine, where lightweight and corrosion-resistant welds are required.

7. Nickel alloy electrodes

Nickel alloy electrodes, such as ENiCrFe-3 and ENiCrMo-3 electrodes, are designed for welding various nickel alloys. These electrodes possess good heat resistance, high strength, and excellent corrosion resistance in extreme environments. They are commonly used in applications involving chemical processing, power generation, and petrochemical industries.

8. Copper alloy electrodes

Copper alloy electrodes, including ERCu and ERCuNi electrodes, are used for welding copper and copper alloys. These electrodes provide good electrical and thermal conductivity, making them suitable for applications requiring excellent heat dissipation. Copper alloy electrodes are commonly used in electrical and electronic industries, as well as in plumbing and heat exchangers.

9. Cast iron electrodes

Cast iron electrodes, such as ENi-C1 and ECI electrode types, are specifically designed for welding cast iron materials. These electrodes have a high nickel content, which helps in minimizing cracking and creating strong welds with cast iron. Cast iron electrodes are widely used in automotive, machinery, and architectural applications.

10. Tungsten electrodes

Tungsten electrodes, including pure tungsten (WP), thoriated tungsten (WT), and lanthanated tungsten (WL) electrodes, are primarily used in tungsten inert gas (TIG) welding. These electrodes possess high melting points and excellent thermal conductivity, making them suitable for welding applications requiring precise control and high-quality welds. Tungsten electrodes are commonly used in industries such as aerospace, nuclear, and automotive.

Applications and Uses

Rutile electrodes

Rutile electrodes are versatile and can be used in a wide range of applications. They are commonly used in automotive, shipbuilding, construction, and general fabrication industries. Rutile electrodes are suitable for welding mild steel, stainless steel, and galvanized steel in various welding positions. They provide good weld bead appearance with minimal spatter and are easy to use, making them ideal for both beginner and experienced welders.

Cellulosic electrodes

Cellulosic electrodes are commonly used in pipe welding to create strong and efficient joints. Their deep penetrating arc and high current settings allow for vertical and overhead welding with ease. Cellulosic electrodes are primarily used in industries such as oil and gas, petrochemical, and pipeline construction. They are well-suited for welding carbon steel and high-strength steel in challenging conditions.

Basic electrodes

Basic electrodes find applications in high-strength steels, low-alloy steels, and critical structures. They are widely used in industries such as construction, infrastructure, and heavy fabrication. Basic electrodes provide excellent mechanical properties, including high crack resistance, which is essential for critical welds. They offer good penetration, easy slag removal, and efficient deposition rates, ensuring strong and reliable welds.

Iron powder electrodes

Iron powder electrodes are commonly used in heavy fabrication and structural welding. Their high metal deposition rates and efficiency make them ideal for welding thicker fillet or groove welds. Iron powder electrodes are often used in construction, shipbuilding, and bridge fabrication industries. They provide high-quality welds, increased productivity, and reduced slag, resulting in cost-effective welding operations.

Stainless steel electrodes

Stainless steel electrodes are used in industries where corrosion resistance is crucial, such as food processing, chemical, and pharmaceutical industries. They are suitable for welding stainless steel and provide excellent mechanical properties and resistance to oxidation and contamination. Stainless steel electrodes ensure clean and sanitary welds, making them essential in industries that require high levels of hygiene and durability.

Aluminum electrodes

Aluminum electrodes are commonly used in industries that require lightweight and corrosion-resistant welds, such as aerospace, automotive, and marine industries. They are designed to weld aluminum and aluminum alloys efficiently. Aluminum electrodes provide good penetration and fusion, resulting in strong and reliable welds. Their use ensures that welded structures maintain their strength and integrity in demanding environments.

Nickel alloy electrodes

Nickel alloy electrodes are employed in applications involving extreme environments, such as chemical processing, power generation, and petrochemical industries. They offer excellent heat resistance, high strength, and superior corrosion resistance. Nickel alloy electrodes are specifically designed to withstand harsh conditions and ensure the longevity of welded structures.

Copper alloy electrodes

Copper alloy electrodes find applications in electrical, electronic, plumbing, and heat exchanger industries. They provide excellent electrical and thermal conductivity, making them suitable for applications requiring efficient heat dissipation. Copper alloy electrodes are essential in creating durable and reliable welds that maintain the desired electrical and thermal performance.

Cast iron electrodes

Cast iron electrodes are primarily used in industries such as automotive, machinery, and architecture, where cast iron materials are common. These electrodes have a high nickel content, ensuring minimal cracking and strong welds with cast iron. Cast iron electrodes allow for the repair and joining of cast iron components, ensuring their longevity and preserving the integrity of the structures.

Tungsten electrodes

Tungsten electrodes are vital in tungsten inert gas (TIG) welding, where precise control and high-quality welds are necessary. They are commonly used in industries such as aerospace, nuclear, and automotive. Tungsten electrodes possess high melting points and excellent thermal conductivity, ensuring efficient heat distribution and excellent arc stability. These electrodes play a crucial role in creating clean and precise welds on various materials.

Factors to Consider when Choosing Electrodes

Base metal

The base metal being welded is a significant consideration when selecting electrodes. Different electrodes are designed to weld specific base metals, such as mild steel, stainless steel, aluminum, cast iron, nickel alloys, copper alloys, titanium, magnesium, high-strength steel, and low-alloy steel. Matching the electrode composition to the base metal ensures optimal weld strength and mechanical properties.

Welding position

The welding position, whether flat, horizontal, vertical, or overhead, impacts the choice of electrodes. Some electrodes, like rutile and basic electrodes, are versatile and suitable for various positions, while others, like cellulosic electrodes, excel in vertical and overhead welding. Selecting electrodes based on the welding position ensures the welder’s comfort and the successful completion of the weld.

Joint type

Different joint types, such as butt joints, fillet joints, lap joints, and corner joints, require specific electrodes for optimal weld quality. Some electrodes penetrate deeply, making them suitable for butt joints, while others provide good fillet welds or have low spatter characteristics for lap joints. Matching the electrode to the joint type ensures proper fusion, strength, and aesthetic appearance of the weld.

Electrode diameter

Electrode diameter plays a crucial role in controlling the heat input during welding. Thicker electrodes (larger diameters) can handle higher current settings and result in faster deposition rates but may lead to higher heat input and potential distortion. Thinner electrodes (smaller diameters) provide greater control and are ideal for precision welding. Selecting the appropriate electrode diameter ensures proper heat distribution and weld quality.

Power source

The type of power source used for welding, whether AC or DC, impacts the selection of electrodes. Certain electrodes are specifically designed for AC or DC welding, while others can be used in both power sources. The power source influences the arc stability, electrode performance, and overall welding process efficiency. Matching the electrode to the power source ensures optimal welding performance and results.

Coating type

The electrode coating type influences the ease of use, arc stability, weld bead appearance, and shielding gas protection. Different coatings, such as rutile, basic, or cellulosic, offer specific characteristics suitable for various applications and welding conditions. Understanding the requirements of the welding project and selecting the appropriate coating type ensures successful and efficient welding operations.

Application temperature

The application temperature, whether low or high, affects the choice of electrodes. Some electrodes are specifically designed to withstand high temperatures, such as those encountered in power generation or chemical processing industries. These electrodes offer excellent heat resistance and maintain their mechanical properties in extreme environments. Considering the application temperature ensures weld quality and longevity.

Mechanical properties

The required mechanical properties of the weld joint, such as strength, ductility, toughness, and corrosion resistance, must be considered when selecting electrodes. Different electrode compositions yield different mechanical properties in the weld. Understanding the desired mechanical properties and matching them to the electrode composition ensures that the weld will possess the necessary strength and durability for its intended use.

Selection Guidelines by Material

Mild steel

When welding mild steel, rutile electrodes, such as E6013 and E6012, are commonly used. These electrodes provide good penetration and are ideal for general-purpose welding applications. They offer excellent weld bead appearance and are suitable for welding in multiple positions. Rutile electrodes with a diameter between 2.5 mm and 3.2 mm are typically used for mild steel.

Stainless steel

Stainless steel electrodes, such as E308 and E316, are specifically designed for welding stainless steel. These electrodes possess excellent corrosion resistance and mechanical properties. For austenitic stainless steels, E308 electrodes are commonly used, while E316 electrodes are suitable for welding duplex and super duplex stainless steels. The electrode diameter depends on the thickness of the stainless steel being welded.

Aluminum

When welding aluminum, aluminum electrodes, such as E4043 and E5356, are typically used. These electrodes offer good penetration and fusion, ensuring strong welds. E4043 electrodes are suitable for welding cast and wrought aluminum alloys, while E5356 electrodes are ideal for welding stronger aluminum alloys. The electrode diameter depends on the thickness of the aluminum being welded.

Cast iron

For welding cast iron, specific cast iron electrodes, such as ENi-CI and ECI, are commonly used. These electrodes have a high nickel content, which helps minimize cracking and produces strong welds with cast iron. Cast iron electrodes are available in various diameters, depending on the thickness of the cast iron being welded.

Nickel alloys

Nickel alloy electrodes, such as ENiCrFe-3 and ENiCrMo-3, are designed for welding various nickel alloys. These electrodes offer excellent heat resistance, high strength, and superior corrosion resistance. The electrode diameter depends on the thickness of the nickel alloy being welded.

Copper alloys

Copper alloy electrodes, such as ERCu and ERCuNi, are used for welding copper and copper alloys. These electrodes provide excellent electrical and thermal conductivity, making them suitable for applications that require efficient heat dissipation. The electrode diameter depends on the thickness of the copper alloy being welded.

Titanium

When welding titanium, specific titanium electrodes, such as ERTi-1 to ERTi-9, are used. These electrodes are designed to weld different grades of titanium, offering high purity and excellent mechanical properties. The electrode diameter depends on the thickness of the titanium being welded.

Magnesium

For welding magnesium, specific magnesium electrodes, such as AZ61A and AZ92A, are commonly used. These electrodes possess good fluidity and penetration, ensuring strong and reliable welds. The electrode diameter depends on the thickness of the magnesium being welded.

High-strength steel

When welding high-strength steel, basic electrodes, such as E7018, are commonly used. These electrodes provide excellent mechanical properties and high-quality welds. The electrode diameter depends on the thickness of the high-strength steel being welded.

Low-alloy steel

For welding low-alloy steel, basic electrodes, such as E7018, are commonly used. These electrodes offer excellent crack resistance and provide superior weld quality. The electrode diameter depends on the thickness of the low-alloy steel being welded.

Factors Affecting Electrode Performance

Moisture content

Moisture content in electrodes can significantly impact their performance. Electrodes with high moisture content can cause hydrogen-induced cracking and result in weak and brittle welds. Proper storage and handling of electrodes, specifically keeping them in sealed containers and using moisture-resistant packaging, can minimize moisture absorption and prevent welding defects.

Storage

Proper storage of electrodes is crucial for maintaining their integrity and performance. Electrodes should be stored in a dry, clean, and temperature-controlled environment. Exposure to moisture, extreme temperatures, and contaminants can degrade the electrodes’ coating and lead to welding defects. Following manufacturer recommendations for storage conditions ensures optimal electrode performance.

Operating temperature

The operating temperature during welding affects electrode performance. Some electrodes have specific operating temperature ranges, beyond which their performance may be compromised. Exceeding the recommended operating temperature can lead to increased spatter, poor arc stability, and reduced weld quality. Monitoring and controlling the operating temperature ensures consistent and high-quality welds.

Welding technique

Different welding techniques, such as shielded metal arc welding (SMAW), gas metal arc welding (GMAW), flux-cored arc welding (FCAW), tungsten inert gas welding (TIG), submerged arc welding (SAW), plasma arc welding (PAW), oxy-fuel gas welding (OFW), and electroslag welding (ESW), require specific electrodes for optimal performance. Understanding the welding technique and selecting compatible electrodes ensure efficient and successful welding operations.

Electrode diameter

Electrode diameter affects welding parameters, heat input, and weld penetration. Thicker electrodes (larger diameters) handle higher current settings and result in faster deposition rates, but may lead to higher heat input and potential distortion. Thinner electrodes (smaller diameters) offer greater control, precise welds, and reduced heat input. Selecting the appropriate electrode diameter ensures proper heat distribution and weld quality.

Current type and magnitude

The type (AC or DC) and magnitude of current influence the performance of electrodes. Some electrodes are designed specifically for AC or DC welding, while others can be used with both types of current. Using the correct current type and magnitude ensures stable arcs, optimal penetration, and spatter control. Following manufacturer recommendations for current settings is vital for optimal electrode performance.

Joint preparation

Proper joint preparation is crucial for successful welding. The joint surface must be clean, free from contaminants, and properly beveled or grooved to allow for proper fusion. Selecting the appropriate electrode based on the joint type and preparing the joint correctly ensure full penetration and strong welds.

Coating thickness

The thickness of the electrode coating can impact welding performance. Excessive coating thickness can affect arc stability, increase spatter, and create slag entrapment issues, while insufficient coating thickness may compromise electrode performance. Selecting electrodes with appropriate coating thickness ensures optimal performance and high-quality welds.

Welding speed

The welding speed, the rate at which the weld progresses, affects electrode performance. Welding too quickly can result in insufficient heat input and inadequate fusion, while welding too slowly can cause excessive heat input and potential distortion. Maintaining the proper welding speed ensures optimal electrode performance, proper fusion, and consistent weld quality.

Welding Techniques with Different Electrodes

Shielded metal arc welding (SMAW)

Shielded metal arc welding, also known as stick or manual metal arc welding, is a versatile welding technique that uses a consumable electrode coated in flux. The flux coating provides shielding gas protection, allowing the welder to create strong welds in various positions and environments. SMAW is commonly used in industries such as construction, maintenance, and repair.

Gas metal arc welding (GMAW)

Gas metal arc welding, commonly known as MIG welding, utilizes a continuous solid wire electrode and a shielding gas to protect the weld pool. GMAW is known for its efficiency and versatility, allowing for high deposition rates and faster welding speeds. This technique is widely used in industries such as automotive, fabrication, and manufacturing.

Flux-cored arc welding (FCAW)

Flux-cored arc welding, similar to GMAW, uses a continuous electrode wire. However, the electrode contains flux inside, eliminating the need for an external shielding gas. FCAW is ideal for welding in outdoor and windy conditions, as the flux provides adequate protection against atmospheric contamination. It is commonly used in industries such as construction, shipbuilding, and heavy fabrication.

Tungsten inert gas welding (TIG)

Tungsten inert gas welding, also known as GTAW or TIG welding, uses a non-consumable tungsten electrode to create an arc. A separate filler metal may be used, depending on the application. TIG welding offers precise control, excellent weld quality, and the ability to weld various metals, including aluminum, stainless steel, and titanium. It is commonly used in industries such as aerospace, nuclear, and precision fabrication.

Submerged arc welding (SAW)

Submerged arc welding utilizes a continuous solid or flux-cored electrode and a granular flux that covers the weld pool completely. The flux provides excellent protection against atmospheric contamination, resulting in high-quality welds. SAW is commonly used in industries such as shipbuilding, pressure vessel fabrication, and large structural welding.

Plasma arc welding (PAW)

Plasma arc welding uses a non-consumable tungsten electrode and a constricted arc to create a high-energy plasma jet. This technique offers excellent control, precise welds, and deep penetration. PAW is commonly used in industries such as aerospace, automotive, and precision fabrication, where high-quality and visually appealing welds are required.

Oxy-fuel gas welding (OFW)

Oxy-fuel gas welding is a technique that utilizes a fuel gas and oxygen to generate a flame for welding. It is commonly used for welding mild steel and copper alloys. OFW is portable and versatile, making it suitable for applications in construction, repair, and plumbing.

Electroslag welding (ESW)

Electroslag welding is a highly efficient welding process used for welding thick sections. It utilizes a consumable electrode and a molten slag, which conducts electrical current and protects the weld pool. ESW is commonly used in industries such as shipbuilding, bridge construction, and heavy fabrication. It provides excellent productivity and facilitates the welding of large structures.

Precautions and Safety Measures

Proper ventilation

Proper ventilation is essential during welding to remove fumes and gases generated from the welding process. Adequate ventilation helps maintain a safe and healthy work environment by preventing the buildup of toxic fumes, such as those containing zinc, lead, or chromium. Ensure the workspace is well-ventilated to protect the welder and others in the vicinity.

Personal protective equipment (PPE)

Welding involves various hazards, including intense heat, UV radiation, flying sparks, and potential exposure to harmful fumes and gases. It is crucial to wear appropriate personal protective equipment (PPE) to ensure the welder’s safety. This includes wearing a welding helmet, safety glasses, gloves, flame-resistant clothing, and respiratory protection, as necessary.

Handling of electrodes

When handling electrodes, it is important to wear appropriate gloves to prevent injury from the sharp ends and edges. Care should be taken to avoid dropping or mishandling the electrodes, as this can damage the coating and affect their performance. Always follow manufacturer guidelines for proper handling to ensure optimal electrode quality.

Storage of electrodes

Proper storage of electrodes is essential to maintain their integrity and performance. Electrodes should be stored in a dry, clean, and temperature-controlled environment to prevent moisture absorption and degradation. Ensure that electrodes are kept in sealed containers or moisture-resistant packaging when not in use.

Electrode identification

It is important to properly identify electrodes before use, as using the wrong type of electrode can lead to welding defects and compromised weld quality. Each electrode is typically labeled with specific information, including the electrode type, diameter, and classification. Always verify that the electrode being used matches the intended application.

Inspection of electrodes

Before use, electrodes should be inspected for any signs of damage, such as cracks, excessive moisture, or coating deterioration. Damaged electrodes should not be used, as they may lead to welding defects. Regularly inspecting electrodes helps ensure their quality and performance.

Proper disposal

Used electrodes should be properly disposed of in accordance with local regulations. Some electrodes may contain hazardous substances, such as heavy metals or toxic coatings, which require careful disposal. Consult local waste management guidelines or recycling facilities for appropriate disposal methods to minimize environmental impact.

Common Welding Defects and their Causes

Porosity

Porosity refers to the presence of small cavities or voids within the weld. It is often caused by factors such as moisture in the electrode, improper shielding gas coverage, or inadequate weld preparation. The presence of porosity weakens the weld and reduces its overall quality.

Weld cracking

Weld cracking can occur due to several factors, including excessive heat input, high levels of residual stress, improper joint preparation, or incorrect electrode selection. Cracks can compromise the structural integrity of the weld and lead to welding failure.

Undercutting

Undercutting is characterized by a groove or depression along the edges of the weld joint. It is primarily caused by excessive heat input or improper welding technique. Undercutting can reduce the weld’s strength and increase the risk of cracking.

Incomplete fusion

Incomplete fusion refers to a lack of proper bonding between the weld metal and the base metal. It can occur due to insufficient heat input, improper welding technique, or inadequate joint preparation. Incomplete fusion can result in weak and unreliable welds.

Spatter

Spatter refers to the expulsion of molten metal particles during welding. It can be caused by factors such as excessive current, improper electrode diameter, or poor electrode coating. Spatter can lead to rough and uneven welds and may require additional cleaning and finishing.

Underfill

Underfill occurs when the weld does not completely fill the intended groove or joint. It can be caused by factors such as low heat input, improper electrode angle, or inadequate welding technique. Underfill compromises the integrity of the weld and reduces its strength.

Stress corrosion cracking

Stress corrosion cracking is a type of cracking that occurs in the presence of specific corrosive environments. It can be caused by factors such as high residual stress levels, improper material selection, or exposure to corrosive substances. Stress corrosion cracking can lead to catastrophic failure of welded structures in severe cases.

Hot cracking

Hot cracking, also known as solidification cracking, occurs during the cooling of the welded joint. It is commonly caused by factors such as high sulfur content in the base metal, excessive heat input, or improper welding technique. Hot cracking can significantly weaken the weld and compromise its integrity.

Distortion

Distortion refers to the deformation or bending of the materials being welded due to the welding process. It can be caused by factors such as high heat input, improper joint preparation, or inadequate clamping or fixturing. Distortion can affect the fit and function of welded structures and may require additional corrective measures.

Brittle fracture

Brittle fracture occurs when the welded joint fractures without significant deformation. It can be caused by factors such as high levels of residual stress, inadequate material toughness, or improper welding technique. Brittle fractures can lead to sudden and unexpected failure of welded components.

Conclusion

In conclusion, welding electrodes play a significant role in various welding processes, providing a means to generate heat and create strong and durable welds. Understanding the different types of welding electrodes, their applications, and factors to consider when selecting and using them is crucial for achieving high-quality welds. By considering factors such as the base metal, welding position, joint type, electrode diameter, and mechanical properties, welders can make informed decisions to ensure successful welding operations. Additionally, adhering to safety measures, such as proper ventilation, personal protective equipment (PPE), and appropriate handling and storage practices, is essential to protect the welder’s health and well-being. By recognizing and addressing common welding defects and their causes, welders can troubleshoot and produce defect-free welds. Overall, knowledge of welding electrodes and their proper usage allows for efficient and effective welding, resulting in strong, reliable, and aesthetically pleasing welds in various industries and applications.