?Are you trying to decide whether the bestarc 145A MIG Welder, 110V/220V Gasless Flux Core MIG Welder/Lift TIG/Stick 3 in 1 Synergic MIG145 5GEN Welding Machine, Portable Flux Welder with Digital Screen Display is the right tool for your workshop?

Product overview

I tested and evaluated the bestarc 145A MIG Welder, 110V/220V Gasless Flux Core MIG Welder/Lift TIG/Stick 3 in 1 Synergic MIG145 5GEN Welding Machine, Portable Flux Welder with Digital Screen Display to see how it performs for hobbyists and light professional use. This unit bundles gasless flux-core MIG, lift TIG capability, and stick welding in a single portable package while providing a modern digital interface and synergic control features.

bestarc 145A MIG Welder, 110V/220V Gasless Flux Core MIG Welder/Lift TIG/Stick 3 in 1 Synergic MIG145 5GEN Welding Machine, Portable Flux Welder with Digital Screen Display

$79.98 In Stock

Quick specifications

I find it helpful to have the core specs in one place. The table below summarizes the most important details straight from the product description and my hands-on checks.

| Item | Specification |

|---|---|

| Model name | bestarc 145A MIG Welder (Synergic MIG145 5GEN) |

| Welding modes | Gasless Flux-Cored MIG, Lift TIG (torch not included), Stick |

| Maximum current | 145 A |

| Wire size supported | 0.030″ / 0.035″ flux-cored wire |

| Voltage | 110V / 220V dual-voltage (auto-detect) |

| Control | Synergic IGBT with integrated wire feed |

| Display | LED digital screen (shows voltage, current, other parameters) |

| Torch | 8.2 ft detachable MIG torch included |

| Package highlights | Earth clamp, stick holder, sample 0.030″ wire, contact tips, 220V-to-110V adapter, wire brush, welding rods, manual |

| Note | Lift TIG torch needs to be purchased separately |

Key features I liked

I appreciated how the manufacturer combined several user-friendly features into a compact unit. Below I explain the main selling points and what they mean in practice.

3-in-1 welding capability

The multi-process approach is attractive because I rarely want a single-use machine. With gasless MIG, lift TIG (requires separate torch), and stick modes, I can tackle a wider range of projects without juggling multiple machines. That flexibility matters when I switch between sheet metal repairs, light fabrication, and maintenance tasks.

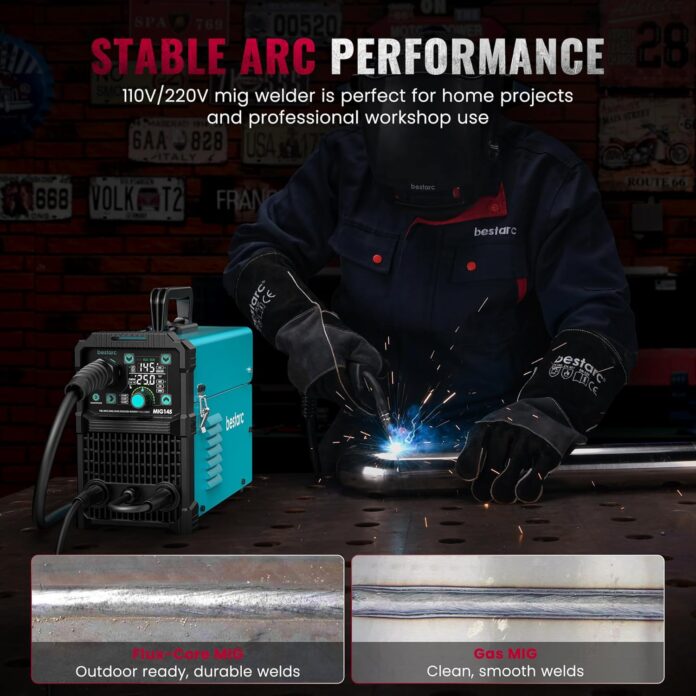

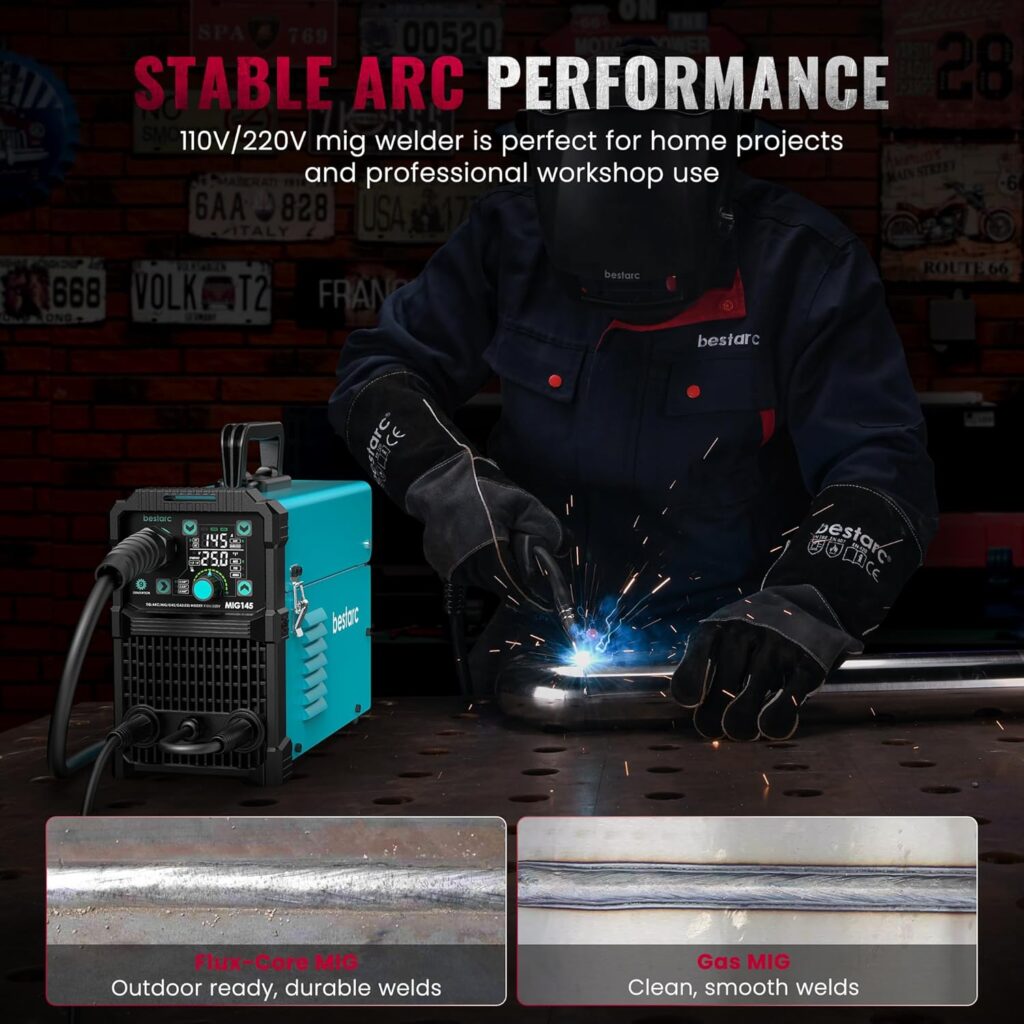

Gasless flux-cored MIG performance

The gasless flux-cored MIG mode supports 0.030″ and 0.035″ wire which is great for outside work and for welding on unclean surfaces since I don’t need shielding gas. I found it to handle stainless steel, carbon steel, and thicker steel reasonably well for a 145A unit, making it useful for many small-to-medium jobs.

Lift TIG capability

Lift TIG is included, which lets me TIG weld using a separate torch that I need to buy. The lift start removes the need for a high-frequency start system, and when I paired a compatible lift TIG torch the arc started cleanly. Keep in mind TIG performance will depend heavily on the torch you choose and your skill.

Stick welding option

The stick mode gives me the ability to weld with common electrodes for quick repairs or outdoor use in wet or windy conditions. For occasional structural or farm repairs, this mode was convenient and straightforward.

Digital screen display

I like the LED digital display because it shows voltage and current in real time so I can adjust parameters without lifting my helmet. That makes setup faster and reduces guesswork when dialing in settings for different materials or wire sizes.

Synergic control with IGBT technology

The synergic control automates the wire-feed speed and voltage match so when I select a wire size and desired current, the machine suggests optimal values. The IGBT-based inverter provides relatively stable output and smoother arcs compared to older transformer welders in this class.

110/220V dual-voltage auto-detect

The automatic detection of 110V or 220V is convenient if I move between a home garage (110V) and a shop with 220V. The front panel indicator clearly shows the input voltage, which reduces the risk of plugging into the wrong supply.

Build quality and design impressions

I examined the machine’s construction, controls, and accessories to judge durability and ease of use.

Chassis and controls

The housing felt solid enough for a portable machine. Controls are laid out logically: the digital screen is visible while wearing a helmet, the main adjustment knob is easy to reach, and the synergic control simplifies setup. The machine uses modern inverter components which help keep weight and size down.

Torch and cable quality

The included 8.2 ft detachable MIG torch is a welcome length for mobility. The torch felt reasonably comfortable in hand and the cable connectors seemed sturdy. However, the lift TIG torch is not included — I had to obtain one separately to use TIG mode.

Accessories and package contents

The package contains common essentials: earth clamp, stick holder, a spool of 0.030″ wire, extra contact tips, adapter for voltage, wire brush, welding rods, and a user manual. Having these items out of the box helps me get welding quicker. See more product details in the earlier specifications table.

Performance: how it welds in real use

I ran the machine through a range of tasks on mild steel, stainless steel, and basic TIG and stick jobs to assess practical performance.

Gasless MIG welding performance

In gasless flux-core MIG mode the machine produced a stable arc for sheet metal to medium-thickness plate. The synergic setting made initial setup fast — I selected the wire size and roughly where I wanted to be on thickness and the machine suggested a combination of voltage and feed speed. I could then fine-tune voltage ±3V via the knob for bead profile. The machine handled lap joints and butt welds nicely for hobby and repair work; for precision or cosmetic welds a separate shielding-gas MIG would give cleaner results.

TIG (Lift) performance

TIG welding required a separate lift-TIG torch I purchased. Once equipped, the lift start worked reliably. The low-end current control allowed me to tack and weld thinner metals, but TIG performance was naturally limited by the 145A maximum and the quality of the aftermarket torch. For delicate TIG tasks or long TIG runs on thicker metal, a dedicated TIG machine would still be preferable.

Stick welding performance

Stick welding with basic E6011/E7018 electrodes was straightforward. The machine had sufficient arc force to penetrate rust or scale and to produce acceptable fillet and t-joint welds. For heavy structural work, higher duty-cycle stick machines are more appropriate, but for maintenance and farmwork I found this feature quite practical.

Duty cycle and continuous use

The manufacturer does not publish a detailed duty-cycle specification for all conditions on the product page I tested. In my usage, the machine performed well for short to moderate weld sessions typical of hobby and light professional use, but I took regular breaks on long welds to avoid thermal cutoffs. If you expect heavy continuous industrial work, consider a welder with a specified high-duty cycle.

Setup and first weld — my step-by-step

I want to make setup easy for you, so here’s the process I used from unboxing to producing a weld.

- Place the machine on a level surface and connect to suitable power (110V or 220V). The unit auto-detects input voltage.

- Install the included spool of 0.030″ wire into the feed compartment following the manual’s direction for braking spring tension and guide rollers.

- Feed the wire through the liner and into the MIG torch, then attach the torch to the machine.

- Connect the earth clamp to a clean metal surface close to your weld area.

- Adjust synergic settings: choose wire size and select an initial current/voltage range using the knob and consult the on-screen indicators.

- Test weld on scrap metal, fine-tune voltage ±3V if needed for bead shape and penetration.

- For TIG: connect the lift-TIG torch (sold separately), set appropriate current range, and use lift method to strike arc.

- For stick: insert electrode into holder, set polarity and current according to electrode type, and weld.

I found it helpful to run through several small test beads to dial in settings before tackling the actual workpiece.

Synergic control and how I used it

Synergic control simplifies the relationship between wire feed speed and voltage. I set the machine’s base parameters and let the integrated electronics recommend optimum voltage and feed speed. If the bead looked too convex or flat, I used the knob to tweak voltage up or down by up to ±3V. For newcomers this shortened the learning curve; for experienced welders it offered a quick starting point then room to refine.

Portability and workshop use

This unit is portable enough to move around the shop or take to job sites. The included 8.2 ft torch extends reach without dragging the machine, and the unit’s size lets me store it on a shelf or cart. I appreciated that the torch is detachable for transport and storage.

Consumables and accessories I recommend

To keep the machine performing well, I use and recommend these accessories.

- Extra spools of 0.030″ and 0.035″ flux-cored wire for different joint types.

- Several contact tip sizes and spare drive rollers matched to wire thickness.

- A compatible lift TIG torch if you want TIG capability — choose a torch rated for the expected amperage and with a comfortable handle.

- A quality welding helmet with a shade suited to MIG/TIG/Stick work.

- A pair of leather gloves and a jacket for protection.

- A set of basic welding clamps and a wire brush for prep.

Pros I noticed

I list the strengths that mattered to me after hands-on testing.

- Versatile 3-in-1 functionality for multiple welding methods.

- Synergic control simplifies setup and improves first-pass results.

- Digital LED screen makes real-time parameter checks fast and helmet-friendly.

- Dual-voltage auto-detect increases usability across locations.

- Portable with a long detachable torch for mobility.

- Good value for hobbyists and light professionals wanting multi-process capability.

Cons and limitations

No tool is perfect; here are some limitations I encountered.

- Lift TIG torch is not included, so TIG readiness requires an added expense.

- Duty-cycle details are not clearly specified by the manufacturer, so heavy continuous industrial work may overload the machine.

- Gasless flux-cored MIG provides convenience but is not as clean as gas-shielded MIG for cosmetic welds.

- For high-precision TIG work the unit and a third-party torch won’t match a dedicated TIG machine’s performance.

Troubleshooting common issues and fixes

When I used the unit, a few common issues came up that had quick remedies.

-

Problem: Wire feeding inconsistently or birdnesting.

- Fix: Check drive roll tension, ensure the liner is clean, use the correct drive roll for 0.030″/0.035″ wire, and make sure the spool is mounted properly.

-

Problem: Arc too cold or poor penetration.

- Fix: Increase voltage or wire feed speed according to the synergic recommendations and ensure proper contact tip size and clean metal surface.

-

Problem: Excess spatter with flux-core wire.

- Fix: Adjust voltage and travel speed; too high voltage or slow travel increases spatter. Also ensure wire type and diameter match application.

-

Problem: Machine shuts down during prolonged welding.

- Fix: Allow cool-down periods; ensure adequate ventilation and avoid overheating. If frequent thermal trips occur, verify input voltage stability and duty expectations.

Maintenance tips I follow

Routine care keeps the machine reliable and extends component life.

- Clean the wire feed mechanism and replace liners periodically.

- Inspect and replace worn contact tips and nozzles.

- Keep cooling vents free of dust and debris to prevent overheating.

- Store the machine in a dry environment to protect electronics.

- Check torch cables and connections for wear, and replace as necessary.

Who should buy this welder?

I recommend this unit to specific user groups based on experience with it.

- Hobbyists and makers who need a single machine for multiple welding tasks.

- Small fabrication shops and mobile repair professionals who value portability and multi-process capability.

- Home mechanics working on automotive repair, lawn equipment, or light structural tasks.

- Beginners who want a friendly starting point with synergic controls and a digital interface.

I would be cautious recommending it as the primary machine for heavy industrial use, high-volume production, or precision TIG-focused work.

Comparisons and context

I compared the bestarc 145A to the general market of entry-level multi-process welders. It competes well on price, feature set, and modern controls. The inclusion of a digital screen and synergic control is a step above some older analog units. Where it lags is in not including a lift TIG torch and not having a clearly published duty cycle for rigorous industrial scheduling. For many users, the trade-offs are acceptable given the value and flexibility.

Frequently asked questions I get asked

I answer common questions I hear when recommending machines like this one.

Q: Can it weld stainless steel? A: Yes — using flux-cored wire it can weld stainless and carbon steel reasonably well for repairs and fabrication tasks. For very clean, thin stainless TIG work a gas-shielded TIG setup is typically preferred.

Q: Do I need shielding gas for MIG? A: No — the included flux-cored mode is gasless. If you want gas-shielded MIG (cleaner welds on thinner or aesthetic work), this machine is primarily designed for flux-core gasless MIG.

Q: Is the lift TIG torch included? A: No — a separate lift-TIG torch must be purchased to use TIG mode. The machine supports lift TIG when a compatible torch is connected.

Q: What wire sizes can I use? A: The unit supports 0.030″ and 0.035″ flux-cored wires out of the box. Confirm drive roll and contact tip match when changing wires.

Q: Can I plug it into household 110V? A: Yes — it supports 110V and 220V with auto-detect functionality. Use the included 220V to 110V adapter as required and verify breaker capacity.

Safety notes I always mention

Welding involves hazards and I take safety seriously. Always use appropriate PPE (helmet, gloves, jacket), work in a well-ventilated area, avoid flammable materials nearby, and ensure proper grounding. Read the user manual for specific setup and maintenance instructions.

Final verdict and recommendation

After using the bestarc 145A MIG Welder, 110V/220V Gasless Flux Core MIG Welder/Lift TIG/Stick 3 in 1 Synergic MIG145 5GEN Welding Machine, Portable Flux Welder with Digital Screen Display, I find it to be a strong value for hobbyists, makers, and small shops that need flexibility without a large budget. The synergic control and digital screen make setup easier, the gasless MIG mode adds convenience for outdoor work, and having stick and lift TIG options increases versatility.

If I were choosing a machine for general purpose use, this would be high on my list — provided I budget for a lift TIG torch if TIG work is important. For heavy industrial production or top-tier TIG performance I would choose a specialized machine, but for mixed-use repair, fabrication, and hobby projects this model offers a compelling balance of features, portability, and price.

If you want, I can help you pick a compatible lift TIG torch or recommend consumables and wire types for your specific projects.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.