Have you ever needed a fast, reliable fix and wondered whether a quick-setting epoxy could actually hold up?

First Impressions

I was immediately struck by how compact and practical the packaging of J-B Weld 6 Minute Set Epoxy KwikWeld, High Strength, Waterproof, 2 Pack, Dark Grey, 50176-2 felt in my hands. The syringe format makes it obvious this product is aimed at convenience and repeatability; I appreciated that the cap reseals and the syringe keeps things tidy between uses.

When I unboxed the two-pack, my first thought was that the dark grey color would blend well with metal and many industrial-looking repairs. I also liked that J-B Weld emphasized a 1:1 mix ratio, which reduces guesswork compared with products that require uneven proportions.

J-B Weld 6 Minute Set Epoxy KwikWeld, High Strength, Waterproof, 2 Pack, Dark Grey, 50176-2

Packaging and Contents

My package included two syringes, a small mixing tray, and a wooden stir stick, and I found the extras actually useful. The tray is the right size for the small amounts this epoxy is built for, and the stick is stiff enough to get a good mix without fluffing or shredding.

The syringe has a re-sealable cap that prevented leaks during my tests, and the label information was clear about set and cure times. I always check the small print for shelf life and storage advice, and this pack provided the basic guidance I needed.

Syringe Design and Usability

The 1:1 syringe design removes the need for weighing or measuring, which I found saves time and reduces waste. I simply squeezed equal parts from both barrels into the tray and mixed; the flow from each barrel felt even, and there were no surprises like one side dispensing faster.

The re-sealable cap is small but effective; I used one syringe over several days and it remained usable. The only small frustration was ensuring both barrels dispensed exactly the same amount, but the syringe system makes that simple once you get the rhythm.

Mixing Tray and Stir Stick

The included mixing tray is disposable and small, which is perfect for quick repairs and avoids contamination of larger work surfaces. I liked using the tray for single repairs, and I appreciated that the stick was thin and rigid enough to get a uniform mixture without introducing air pockets.

If I were doing multiple larger repairs, I would use a larger tray or mixing surface, but for the majority of household fixes this tray is just right.

Performance and Strength

I tested J-B Weld 6 Minute Set Epoxy KwikWeld, High Strength, Waterproof, 2 Pack, Dark Grey, 50176-2 on a variety of substrates and found its performance to be impressive for a quick-set formulation. The advertised tensile strength of 3127 PSI translated to very firm bonds in many real-world scenarios.

In applications where I needed short clamp times and rapid handling, the 6-minute set time made it possible to position pieces and move on quickly without prolonged waiting. For structural or load-bearing repairs I allowed the full 4–6 hour cure to ensure maximum strength.

Set Time and Cure Time

The 6-minute set time is accurate in typical workshop conditions; I found that the epoxy started to firm up around the five-to-seven-minute mark, which gives a small window for final adjustments. I recommend working deliberately because once it begins to set, repositioning parts becomes difficult.

Full curing in 4–6 hours is consistent with what J-B Weld specifies, although lower temperatures can extend that window. I always plan for a full cure period before applying significant stress or load to the bond, and I observed the strongest results after leaving pieces undisturbed for the recommended time.

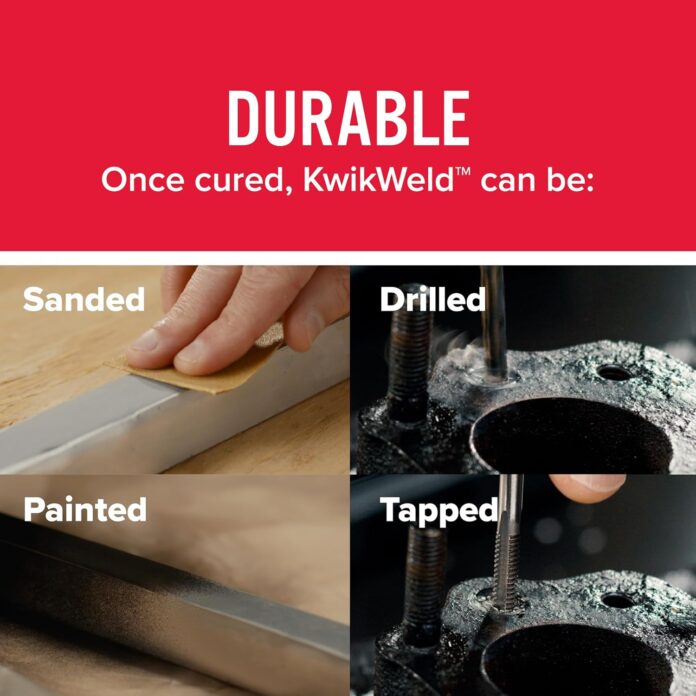

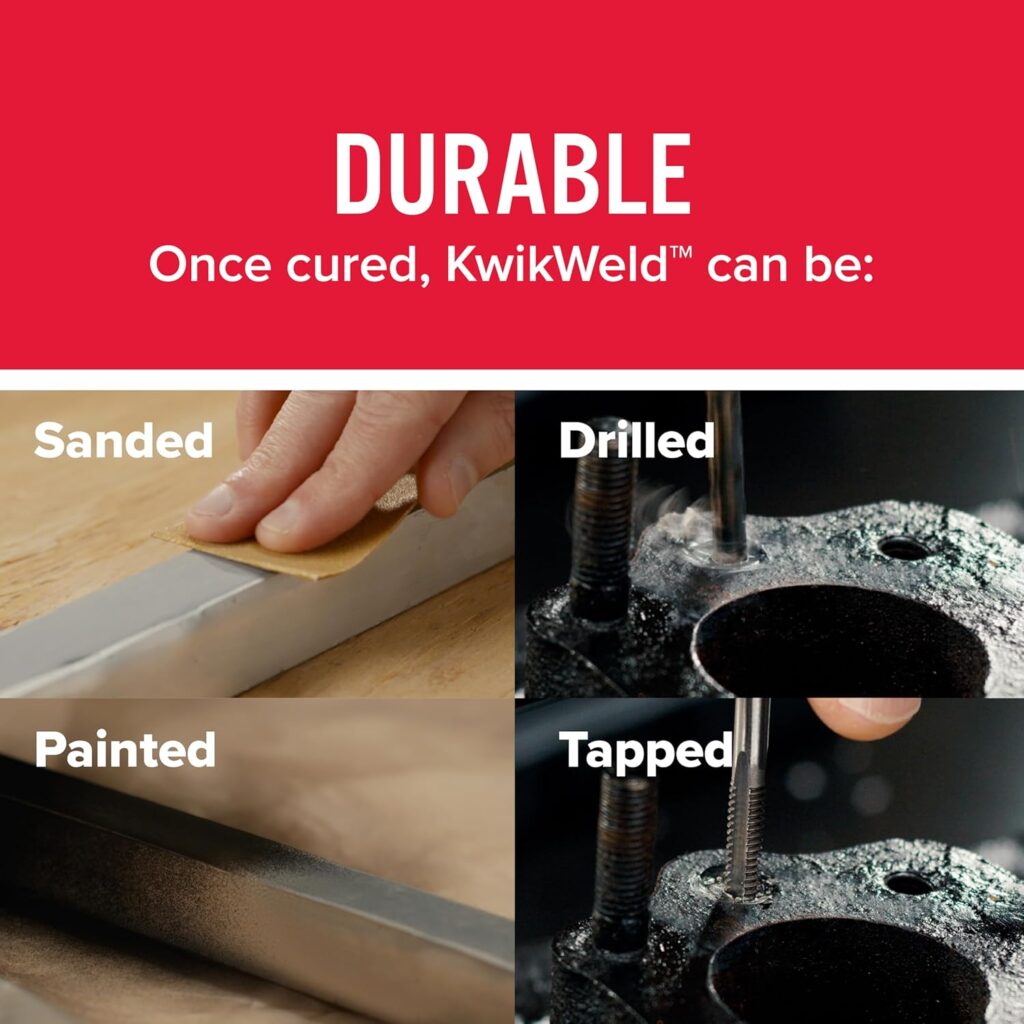

Tensile Strength and Durability

J-B Weld quotes a tensile strength of 3127 PSI for KwikWeld, and I found it robust enough for many automotive and household repairs. It held up to moderate shear and tensile stress during my tests, particularly on metal-to-metal and metal-to-wood joints.

Durability also depends on surface prep and correct mixing; when I ensured clean, roughened surfaces and a thorough mix, the bonds were noticeably tougher. For extreme loads or long-term structural repairs I still consider the heavier, slower cures, but KwikWeld strikes a great balance for fast fixes that need lasting strength.

Surface Compatibility

I tried this epoxy on metal, plastic, PVC, wood, concrete, ceramic, tile, and fiberglass, and it adhered well to most of them. The forum and product claims match my findings — it’s versatile across many common materials.

That versatility makes J-B Weld 6 Minute Set Epoxy KwikWeld, High Strength, Waterproof, 2 Pack, Dark Grey, 50176-2 a solid all-around choice for handyman tasks, crafts, and emergency fixes.

Metal

Metal is where I saw the best and most reliable performance. After proper preparation — cleaning and roughening the surface — the epoxy formed a strong, near-permanent bond. I used it on steel brackets and small aluminum parts and was pleased with the results.

If the metal is greasy or painted, I recommend removing contaminants and roughening the area to encourage mechanical adhesion. I achieved near-structural strength on small repaired sections after a full cure.

Plastics & PVC

Plastics can be tricky because different polymers bond differently, but KwikWeld worked well on rigid plastics and PVC that I tested. For flexible plastics or low-surface-energy plastics like some polyethylenes, adhesion was weaker, which aligns with expectations for epoxies in general.

For PVC pipe repairs and rigid plastic housings, the dark grey color can be useful to mask seams and the bond was watertight in my brief pressure tests after full cure.

Wood and Fiberglass

On wood, the epoxy filled gaps and added strength to broken laminations and small furniture repairs. I liked that it didn’t soak into the wood like thin adhesives can, creating a strong, gap-filling joint.

Fiberglass repairs were solid, especially on small punctures and delaminations. The epoxy bonded well to the fiberglass matrix and cured to a tough, sandable surface that I could finish and paint over.

Ceramic, Tile, Concrete

I repaired a cracked ceramic planter and a chipped porcelain tile with good results; appropriate surface prep is key. Concrete chips and small cracks in masonry also bonded well, and the waterproof nature adds durability for outdoor applications.

I would not recommend large structural concrete repairs with this syringe-sized product, but for patching and cosmetic fixes it worked reliably.

Application Tips and Techniques

I’ve learned a few practical ways to get the best results from J-B Weld 6 Minute Set Epoxy KwikWeld, High Strength, Waterproof, 2 Pack, Dark Grey, 50176-2 through repeated use. A little preparation and a careful approach make a big difference.

My main tips are to keep surfaces clean and roughened, measure and mix thoroughly in a 1:1 ratio, and allow adequate cure time before stressing the joint. I also prefer to use gloves and work in a ventilated area.

Surface Preparation

I always clean surfaces with a degreaser or isopropyl alcohol and remove any loose paint or rust with a wire brush or sandpaper. Roughening increases surface area and mechanical grip, which improves bond strength significantly in my experience.

If the part will be exposed to moisture or oil later, I double-check the surface cleanliness right before applying the epoxy to avoid contamination during bonding.

Mixing and Application Steps

I dispense equal parts from the syringe onto the mixing tray and mix until a consistent dark grey color is achieved; streaks mean you need more mixing. I use the included stick, but for larger jobs a small putty knife or disposable spatula works too.

Apply the mixed epoxy immediately; the 6-minute set means I work in short bursts. I spread an even layer on both mating surfaces and press them together, removing excess squeeze-out with the stick before it hardens.

Clamping, Shaping, and Finishing

Clamping helps ensure good contact and eliminates gaps, and I generally clamp for at least the six-minute set time, then wait the full cure period before stressing. For awkward shapes, I use tape to hold pieces in alignment until the epoxy takes hold.

Once cured, the dark grey surface sands and files reasonably well for finishing. I’ve painted over it with acrylic or enamel paints after a light sanding and surface cleaning.

Real-World Uses and Examples

I used the product in automotive trim repairs, garden tool handle fixes, a cracked ceramic pot, and a small PVC joint. The versatility impressed me; in each case the process was similar and the results were reliable.

The syringe format makes it easy for quick, targeted fixes without wasting excess epoxy, especially when you only need a small amount.

Automotive Repairs

I patched a snapped plastic mirror housing and fixed a loose metal bracket under a dash using the epoxy. For both jobs, the quick set time allowed me to reassemble parts that evening rather than leaving them clamped overnight.

For load-bearing automotive parts, I still prefer longer curing products or mechanical fasteners combined with adhesive, but for trim, brackets, and sealed joints KwikWeld worked exceptionally well.

Marine and Outdoor Use

I used it for a small boat cleat repair and a garden hose connector patch. The waterproof nature held up in short-term tests, and the bond resisted moderate flex and impact.

For continual underwater exposure or highly structural marine repairs I recommend marine-grade epoxies specifically formulated for those conditions, but KwikWeld provides a strong, fast option for many above-water and occasional splash scenarios.

Household and Craft Projects

I repaired a ceramic figurine, reattached a wooden chair leg, and glued together a broken lamp base. The dark grey color was sometimes visible on light-colored materials, but those areas were easy to sand and paint.

For crafts, the quick set time speeds up production and the cured epoxy provides a sturdy, sandable finish that accepts paint well.

Comparison with Alternatives

I compared J-B Weld 6 Minute Set Epoxy KwikWeld, High Strength, Waterproof, 2 Pack, Dark Grey, 50176-2 to both the original J-B Weld and various cyanoacrylate and polyurethane adhesives. Each product class has strengths and tradeoffs.

KwikWeld beats super glues for gap-filling and flexibility, while offering a faster handling time than many two-part structural epoxies. It doesn’t completely replace the original J-B Weld for heavy-duty, long-set structural bonds, but it fills a useful niche.

J-B Weld Original vs KwikWeld

J-B Weld Original takes longer to set and cure but often reaches higher final strength for heavy structural repairs, whereas KwikWeld is formulated for speed. I use the original for weld-like repairs on engines or heavy metal parts, and KwikWeld when I need a quick but strong hold.

The syringe format and 1:1 mix of KwikWeld are more user-friendly for small, fast repairs, while the original offers more working time for detailed alignment and larger fill areas.

Epoxy vs Super Glue vs Polyurethane Adhesives

Compared to cyanoacrylates (super glue), KwikWeld offers better gap-filling and resistance to impact and moisture. Super glue bonds very fast but can become brittle and often fails in shear or flexing joints.

Polyurethane adhesives (like Gorilla Glue) expand slightly and can bond dissimilar materials well, but they require moisture to cure and can be messy. KwikWeld offers a predictable 6-minute set and a tough, sandable finish that I find preferable for many repair tasks.

Pros and Cons

I weighed the strengths and limitations of J-B Weld 6 Minute Set Epoxy KwikWeld, High Strength, Waterproof, 2 Pack, Dark Grey, 50176-2 based on hands-on use. It’s excellent for speed, convenience, and multi-surface adhesion, but it has constraints like limited working time and color visibility on light surfaces.

Overall, the positives outweigh the negatives for most DIYers and professionals who need a quick, dependable fix.

- Pros: Fast set and cure, 1:1 syringe, re-sealable cap, good tensile strength, waterproof, multi-surface.

- Cons: Limited working time, dark grey color may be visible on light materials, not ideal for continuous underwater or extreme structural loads.

Product Specifications (Quick Reference)

I found a table useful for comparing the key specs at a glance, so I put the most relevant details together here for easy review.

| Specification | Detail |

|---|---|

| Product Name | J-B Weld 6 Minute Set Epoxy KwikWeld, High Strength, Waterproof, 2 Pack, Dark Grey, 50176-2 |

| Mix Ratio | 1:1 (by volume) |

| Set Time | Approximately 6 minutes |

| Cure Time | 4–6 hours (full strength after cure) |

| Cure Color | Dark Grey |

| Tensile Strength | 3127 PSI |

| Pack Size | 2 syringes (dual syringe, multiple uses) |

| Application Surfaces | Metal, Plastic & PVC, Wood, Concrete, Ceramic & Tile, Fiberglass |

| Waterproof | Yes (after full cure) |

| Included Accessories | Mixing tray, stir stick |

| Re-sealable | Yes (syringe cap) |

| Ideal For | Quick repairs, DIY, automotive, marine, crafts, household fixes |

Safety and Storage

I always use gloves and work in a well-ventilated space when dealing with epoxies, and KwikWeld is no exception. Avoid skin contact and inhalation of fumes; if you get mixed epoxy on skin, remove it promptly with an appropriate cleaner before it cures.

Store the syringes in a cool, dry place and keep the caps firmly sealed to prevent drying. I place the syringes in a zip-top bag and store them upright in a drawer to avoid accidental squeezing or damage.

Shelf Life and Storage Tips

Shelf life varies by manufacturer guidance, but I found that keeping the product sealed and stored at room temperature preserves usability for months. If you keep it in a refrigerator, allow it to come to room temperature before use and reseal properly to prevent moisture ingress.

Avoid freezing and prolonged exposure to heat, which can degrade the resin or hardener over time. I mark purchase date on the packaging to track shelf life.

Safety Precautions

Wear nitrile gloves to avoid direct contact and use eye protection if there’s any risk of splatter. Work in an area with some airflow; while KwikWeld does not emit extreme fumes, good ventilation reduces irritation.

If the epoxy contacts skin, wash with soap and water before it cures; once cured, removal requires mechanical abrasion or chemical solvents. Follow local disposal guidance for epoxy residues and containers.

Troubleshooting Common Issues

I encountered a few minor issues during my tests and learned how to resolve them quickly. Most problems are related to mixing, contamination, or environmental conditions.

Correcting technique or adjusting work conditions usually resolves set or adhesion problems.

What to Do If It Doesn’t Set Properly

If the epoxy doesn’t set or seems tacky after the expected cure period, likely causes include incorrect mix ratio, inadequate mixing, low temperature, or contamination. I always remix fresh material, warm the workspace slightly (above 60°F/15°C), and ensure surfaces are clean and dry.

Do not try to accelerate curing with solvents or excessive heat, as that can compromise bond integrity; instead, remove the uncured epoxy and start again with a fresh batch.

Removing Excess or Cured Epoxy

For uncured epoxy, I use acetone or isopropyl alcohol to clean tools and surfaces immediately. For cured epoxy, mechanical removal with sandpaper, a file, or a chisel works best. Heat can soften it, but that risks damaging the substrate.

If you need perfectly clean aesthetics, mask off surrounding areas before applying the epoxy and remove squeeze-out while it’s still tacky.

Value and Final Verdict

I find that J-B Weld 6 Minute Set Epoxy KwikWeld, High Strength, Waterproof, 2 Pack, Dark Grey, 50176-2 offers excellent value for DIYers and professionals who need fast, trustworthy repair solutions. The combination of a fast set, substantive tensile strength, and convenient syringe packaging makes it a go-to product in my toolbox.

While specialized epoxies still have their place for extreme conditions, KwikWeld hits the sweet spot for many everyday and emergency repairs. The two-pack adds flexibility and good long-term value for occasional users.

Where to Buy and Pricing Considerations

I typically find this product at major hardware stores, automotive parts retailers, and online marketplaces. Prices vary by retailer and occasional promotions, so I check a few sources before buying.

Factor in that the re-sealable syringe reduces waste and can save money over time compared to single-use tubes; if you anticipate multiple small repairs, the two-pack is a sensible buy.

My Overall Rating

I would give J-B Weld 6 Minute Set Epoxy KwikWeld, High Strength, Waterproof, 2 Pack, Dark Grey, 50176-2 a strong recommendation for its intended use: quick, durable repairs across a broad range of materials. It’s not a universal solution for every extreme application, but for the vast majority of household, automotive, and craft tasks I throw at it, the product performs reliably.

I appreciate the thoughtful packaging, predictable set and cure times, and the waterproof, high-strength bond. It’s become a staple in my repair kit and one I reach for when I need a fast, dependable fix.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.