Are you looking to dive into the world of welding, but wondering how to prepare your metal for this exciting process?

Look no further, as we uncover the best techniques to ensure your welding projects are successful.

From cleaning the metal surface to removing any contaminants that could affect the bond, we’ll guide you through the essential steps for achieving strong and durable welds.

So, grab your welding gear and get ready to learn the secrets of optimal metal preparation!

Choosing the Right Metal for Welding

Before you begin the welding process, it is crucial to choose the right metal for your project. The metal’s composition plays a significant role in determining its weldability and the strength of the final weld. Different metals have varying melting points and react differently to heat, so understanding their composition is essential.

Understanding the Metal’s Composition

To choose the right metal for welding, you must have a good understanding of its composition. Different metals, such as carbon steel, stainless steel, aluminum, and copper, have distinct properties that affect the weldability. Consider factors like carbon content, alloying elements, and heat conductivity when selecting the metal for your welding project.

Identifying the Metal Type

Identifying the metal type is crucial in determining the appropriate welding technique and filler material to use. Various methods can help you identify the metal, such as visual inspection, spark testing, and magnetic properties. Once you have identified the metal, you can proceed with the necessary preparations.

Determining its Weldability

Not all metals are easily weldable, so determining the metal’s weldability is vital. Some metals, like carbon steel and stainless steel, are commonly welded, while others, like cast iron, require special procedures. You can consult welding charts or seek advice from experts to determine the weldability of the specific metal you are working with.

Considering the Metal Thickness

The thickness of the metal also affects the welding process. Thicker metals require more heat and welding passes to ensure proper fusion. It is essential to consider the metal thickness when selecting the welding technique and equipment to ensure a strong and durable weld.

Cleaning and Removing Contaminants

Preparing the metal surface by cleaning and removing contaminants is crucial to achieve a high-quality weld. Contaminants like paint, coatings, grease, rust, and corrosion can negatively impact the welding process and the integrity of the weld.

Removing Paint and Coatings

Paint and coatings must be completely removed from the metal surface before welding. Using paint strippers, sanding, or scraping can effectively remove these coatings. Ensure that no traces of paint or coatings remain to achieve a clean surface for welding.

Degreasing the Metal Surface

Grease and oil can prevent proper fusion during welding, leading to weak and unreliable welds. Using suitable degreasers, solvents, or alkaline cleaners can effectively remove grease and oil from the metal surface. Make sure to thoroughly clean the metal to eliminate any residue before proceeding with welding.

Cleaning with Solvents

Solvents can be used to remove stubborn contaminants from the metal surface. They are particularly effective in removing oils, greases, and other organic residues. However, it is essential to handle solvents with care and wear proper safety equipment when using them.

Removing Rust and Corrosion

Rust and corrosion can significantly weaken the metal and affect the quality of the weld. Various methods, such as wire brushing, sanding, or chemical rust removers, can be used to remove rust and corrosion. Ensure that the metal surface is free from any signs of rust or corrosion before proceeding with welding.

Mechanical Cleaning Methods

Mechanical cleaning methods involve physically removing contaminants and preparing the metal surface for welding. These methods are effective in removing stubborn residues and providing a clean surface for welding.

Grinding and Sanding

Grinding and sanding are commonly used mechanical cleaning methods. They involve using abrasive tools, such as grinding discs or sandpaper, to remove coatings, rust, and other contaminants. These methods are particularly useful for preparing large metal surfaces or removing thick layers of contaminants.

Wire Brushing

Wire brushing is an excellent method for removing loose rust, paint, or coatings. It involves using wire brushes with stiff bristles to scrub the metal surface, effectively removing contaminants. Wire brushing is generally used for smaller areas or for providing a final cleaning touch before welding.

Blasting

Blasting, such as sandblasting or shot blasting, is an efficient method to clean large metal surfaces. It involves using high-pressure air or a stream of abrasive particles to remove contaminants, rust, and old paint. Blasting is particularly effective for preparing metal surfaces that will be painted or coated after welding.

Using Abrasive Pads or Discs

Abrasive pads or discs are another mechanical cleaning method that can be used for smaller or hard-to-reach areas. These pads or discs come in various grit sizes and can effectively remove light coatings, rust, or other contaminants. They can be attached to handheld tools or used with power tools for convenience.

Chemical Cleaning Methods

Chemical cleaning methods involve using cleaning solutions or chemicals to remove contaminants from the metal surface. These methods can be particularly useful for removing stubborn or hard-to-reach contaminants.

Pickling and Passivation

Pickling and passivation are common chemical cleaning methods used for stainless steel. Pickling involves immersing the stainless steel in an acid solution to remove surface impurities and enhance corrosion resistance. Passivation, on the other hand, involves treating the metal with an oxidizing agent to create a passive oxide layer that protects against corrosion.

Acid Cleaning

Acid cleaning involves using acids, such as hydrochloric acid or sulfuric acid, to remove rust, scale, and other contaminants from the metal surface. It is important to handle acids with caution and follow proper safety procedures when using them. Acid cleaning can be highly effective but should only be used on metals that can withstand the corrosive nature of the acids.

Alkaline Cleaning

Alkaline cleaning uses alkaline solutions to remove grease, oil, and other organic contaminants from the metal surface. Alkaline cleaners are often less corrosive than acids and are generally safer to use. They are ideal for cleaning metals that are sensitive to acid solutions.

Electrochemical Cleaning

Electrochemical cleaning, also known as electrolytic cleaning, involves using an electrolyte solution and an electrical current to remove contaminants from the metal surface. This method is particularly effective for cleaning intricate or delicate parts, as it can reach areas that are difficult to access with other cleaning methods.

Surface Preparation Techniques

Surface preparation techniques play a crucial role in achieving a strong and reliable weld. These techniques ensure proper joint fit-up, remove metal oxides, and create bevels that facilitate better fusion between the metal pieces.

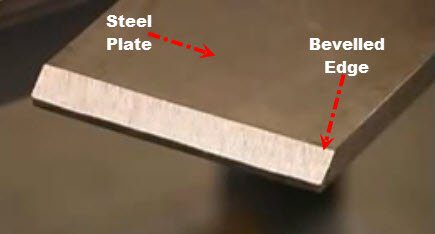

Creating Bevels

Creating bevels involves cutting or grinding an angled edge along the metal pieces to be welded. Bevels allow for more significant penetration during welding, resulting in stronger and more durable welds. The specific angle and depth of the bevel depend on the metal thickness and welding process being used.

Achieving Proper Joint Fit-up

Proper joint fit-up is essential for ensuring a successful weld. It involves ensuring that the metal pieces to be welded are aligned correctly. Utilizing clamps or fixtures can help hold the pieces in place during welding and maintain proper alignment. Proper fit-up ensures that the metals will fuse together effectively.

Using Backing Bars

Backing bars are commonly used when welding thicker metals or when a complete penetration weld is required. These bars provide support on the backside of the weld joint, preventing distortion and ensuring full penetration. Backing bars can be made of materials that match the base metal or dissolvable materials that can be easily removed after welding.

Removing Metal Oxides

Metal oxides, such as rust or scale, can hinder the fusion of the metals during welding. Mechanical or chemical cleaning methods can be used to remove these oxides and achieve a cleaner surface for welding. It is essential to remove all metal oxides before welding to ensure a strong and reliable weld joint.

Preheating the Metal

Preheating the metal before welding can be necessary in some cases to prevent issues like cracking or distortion. Preheating helps equalize the temperature of the metal and minimizes the difference between the welding temperature and the surrounding metal.

Determining the Preheating Requirements

The preheating requirements vary depending on the metal type, thickness, and welding process being used. Referring to welding codes, standards, or consulting with experts can help determine the necessary preheating temperature and duration. Failure to preheat adequately in certain situations can lead to weld defects and compromises the integrity of the weld joint.

Using Torches or Induction Heating

Preheating can be done using various methods, such as flame torches or induction heating. Flame torches produce an open flame, which provides the required heat. Induction heating, on the other hand, uses electromagnetic fields to generate heat within the metal. Both methods are effective in preheating the metal to the desired temperature.

Monitoring the Preheating Temperature

Maintaining the correct preheating temperature is crucial to ensure a successful weld. Using temperature-indicating devices, such as temperature crayons or infrared thermometers, can help monitor the preheating temperature accurately. Regularly checking and adjusting the preheating temperature throughout the welding process is necessary to prevent overheating or underheating.

Preventing Warpage and Distortion

Preheating the metal can help minimize warpage and distortion during welding. By equalizing the temperature of the base metal and reducing thermal stress, preheating allows for more controlled and stable welding. This is particularly important when working with thicker metals or when welding complex structures.

Using Clamping and Fixturing

Clamping and fixturing are essential techniques to ensure proper alignment, prevent movement during welding, and reduce the chances of heat sinkage. Choosing the right clamps and fixtures and using them correctly can significantly improve the quality of your welds.

Choosing the Right Clamps and Fixtures

Selecting the appropriate clamps and fixtures for your welding project is crucial. Consider factors such as the material being welded, the joint type, and accessibility when choosing clamps and fixtures. Welding supply stores or experts can provide guidance on the most suitable clamps and fixtures for your specific needs.

Ensuring Proper Alignment

Proper alignment of the metal pieces to be welded is essential to achieve strong and reliable welds. The use of clamps and fixtures can help hold the metals in place during welding, ensuring that they do not move or shift. Careful alignment before welding is crucial for successful fusion and avoiding defects.

Preventing Heat Sink

Heat sinkage occurs when a significant amount of heat is absorbed by a nearby metal object, such as a thick plate or structure. This can result in inadequate penetration of the weld and weak joints. Using proper clamping and fixturing techniques can help prevent heat sinkage by isolating the heat-affected zone and allowing for proper fusion.

Utilizing Magnetic Clamps

Magnetic clamps are commonly used when conventional clamps or fixtures cannot be used due to accessibility or other factors. Magnetic clamps provide a strong magnetic hold, ensuring that the metal pieces stay in position during welding. They can be particularly useful when working with thin or non-ferrous metals.

Protecting Adjacent Areas from Welding Spatter

Welding spatter is the small molten metal droplets that can fly off during the welding process. These spatter particles can cause damage or leave unsightly marks on adjacent areas. Proper protection measures can prevent spatter-related issues during welding.

Using Fire-Resistant Materials

Using fire-resistant materials, such as fire-resistant blankets or shields, can effectively protect nearby areas from welding spatter. These materials are designed to withstand high temperatures, reduce the risk of fire, and prevent damage to surrounding objects or structures.

Using Heat-Resistant Blankets or Curtains

Heat-resistant blankets or curtains can be used to enclose the welding area and prevent spatter from reaching adjacent surfaces. These blankets or curtains are made from flame-resistant materials that can withstand the high temperatures generated during welding.

Applying Spatter-Resistant Coatings

Applying spatter-resistant coatings to nearby surfaces can provide an additional layer of protection against welding spatter. These coatings are designed to repel spatter, making it easier to remove any spatter that lands on them without causing damage.

Protecting Sensitive Components

In some cases, welding may need to be performed near sensitive components or electronic equipment. Using specialized barriers or shielding can effectively protect these components from spatter and prevent any damage or interference. It is crucial to take extra precautions when working in such environments to ensure the safety of both the welding process and the sensitive components.

Correcting Distortion and Warping

Distortion and warping are common issues that can occur during welding. These issues can compromise the structural integrity of the weld joint and affect the overall quality of the completed project. Corrective measures can help address and minimize distortion and warping.

Understanding Causes of Distortion

Distortion and warping can be caused by factors such as uneven heating, improper weld sequencing, or inadequate fixturing. By understanding the causes of distortion, you can implement appropriate corrective measures to minimize their occurrence.

Applying Welding Sequence and Technique

Proper welding sequence and technique can significantly reduce distortion and warping. This involves carefully planning the order in which welds are made and using the appropriate welding technique for the specific joint and metal being welded. Following recommended welding procedures and techniques can help control the heat input and minimize distortion.

Using Heat Sinkage Techniques

Heat sinkage techniques involve distributing heat more evenly across the metal to minimize distortion. This can be achieved by intermittently cooling sections of the metal or using heat sinks, such as copper bars, to absorb excess heat during welding. Heat sinkage techniques are particularly useful when working with heat-sensitive or thin metals.

Utilizing Corrective Straightening Methods

If distortion or warping occurs despite preventive measures, corrective straightening methods can be used to restore the metal to its intended shape. These methods involve applying controlled force and heat to bend or reshape the affected areas. It is important to seek advice from experts or refer to welding standards when performing corrective straightening to ensure the structural integrity of the weld joint is maintained.

Post-Weld Cleaning and Finishing

After welding, it is essential to clean the weld area to remove any welding slag, flux, or other residues. Additionally, depending on the specific requirements of the project, the weld bead may require further cleaning or finishing.

Removing Slag and Flux

Slag and flux are byproducts of the welding process and need to be removed to achieve a clean and visually appealing weld. Various cleaning methods, such as wire brushing, grinding, or chipping, can help remove welding slag and flux effectively. It is important to remove all residues to prevent corrosion and ensure the weld’s longevity.

Cleaning Weld Beads

Weld beads can be rough or uneven, depending on the welding process used. Hence, cleaning and smoothing the weld beads may be necessary to achieve a polished and aesthetically pleasing finish. Grinding or polishing tools can be used to clean and smoothen weld beads, ensuring a professional appearance.

Grinding or Polishing

Grinding or polishing the weld area and adjacent surfaces can improve the appearance and quality of the weld. These methods help remove any surface imperfections, slag, or rough edges, resulting in a smoother, more refined weld. The level of grinding or polishing required depends on the project’s specific requirements and aesthetic preferences.

Applying Protective Coatings or Paint

To provide long-term protection against corrosion and improve the weld’s overall appearance, applying protective coatings or paint may be necessary. These coatings act as a barrier, preventing moisture and other corrosive elements from reaching the underlying metal. Depending on the metal type and environment, different coatings or paints may be recommended.

By following these guidelines for preparing your metal for welding, you can ensure a successful and high-quality welding project. Remember to choose the right metal, clean the surface thoroughly, and use appropriate techniques and protective measures.

Taking the time to properly prepare your metal will result in strong, reliable welds and a finished product that meets your expectations. happy welding!