So you’ve had this burning question: Can I weld underwater? Well, you’ll be relieved to know that the answer is yes!

Welding underwater is not only possible, but it’s highly specialized skill with a wide range of applications. From repairing oil rigs to constructing underwater structures, underwater welding opens up a new world of possibilities.

In this article, we will explore the fascinating world of underwater welding and delve into the techniques, challenges, and safety precautions involved in this unique profession.

So, fasten your oxygen tanks, and let’s dive into the depths of underwater welding!

Safety Considerations

Underwater welding is a challenging and specialized process that requires careful consideration of safety measures. It is essential to prioritize protective equipment, undergo proper underwater welding training, be aware of environmental hazards, follow electrical safety guidelines, and take diving precautions.

Protective Equipment

Wearing the appropriate protective equipment is vital to ensure your safety when engaging in underwater welding. This includes a full-face diving mask or helmet with built-in welding goggles to protect your eyes from the intense light and harmful radiation produced during welding. Additionally, a dry or wet suit should be worn to protect your body from the cold water and potential contact with contaminants.

Underwater Welding Training

Before attempting underwater welding, receiving specialized training from certified institutions is crucial. Underwater welding requires unique skills and knowledge due to the underwater environment and the specific challenges it presents. Proper training will teach techniques, safety procedures, and equipment handling skills. By obtaining the appropriate training, you will become well-prepared to tackle the complexities of underwater welding.

Environmental Hazards

Working underwater exposes welders to various environmental hazards. One significant concern is the presence of marine life, such as electric rays or jellyfish, which can cause injuries if proper precautions are not taken.

Additionally, underwater welding often occurs in saltwater environments, which may accelerate corrosion. Other potential hazards include strong currents, limited visibility, and unpredictable weather conditions. Awareness of these environmental hazards and taking necessary precautions is crucial for safety during underwater welding operations.

Electrical Safety

Underwater welding involves working with electricity in a unique environment, which requires strict adherence to electrical safety guidelines. Engaging in proper grounding and insulation procedures is essential to prevent electrical shocks.

Additionally, the welding equipment used underwater must be specially designed to withstand challenging conditions and ensure user safety. Regular equipment inspections and maintenance are necessary to minimize the risk of electrical hazards.

Diving Precautions

As underwater welding involves working at significant depths, it is crucial to prioritize diving safety. Proper training in diving techniques, including decompression procedures, is necessary to minimize the risk of decompression sickness.

Properly maintaining diving equipment, such as air tanks and regulator systems, ensures optimal functionality and reliability underwater. Regularly monitoring your dive time and adhering to safe diving practices will contribute to a safer underwater welding experience.

Types of Underwater Welding

Underwater welding can be classified into three main types: dry, wet, and hyperbaric. Each type has its unique characteristics and applications.

Dry Welding

Dry welding is performed in a dry environment inside a sealed habitat or chamber. The welding is carried out by creating a dry space around the welding joint, which allows for more controlled conditions. This type of welding is commonly used for large-scale projects and repairs that divers cannot easily access. By creating a dry environment, welders do not have to contend with the challenges of working underwater, such as limited visibility and turbulence.

Wet Welding

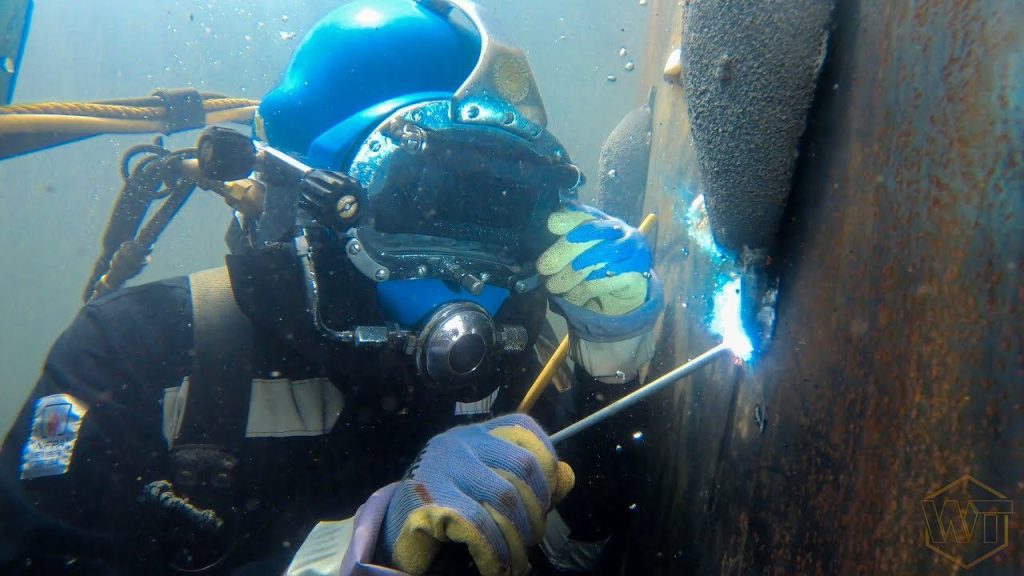

Wet welding is a method where welding is conducted directly in the water without using a sealed chamber.

This technique is frequently used in underwater welding applications as it provides more flexibility and accessibility. Wet welding requires specialized equipment, such as waterproof electrodes and specially designed power sources. Welders specializing in wet welding must be skilled in working underwater, dealing with limited visibility and turbulence.

Hyperbaric Welding

Hyperbaric welding involves welding in a submerged environment under high pressure. It is typically performed in a hyperbaric chamber, which allows for controlled conditions and protects the weld from contact with water.

This method is often used for critical welds that require a high level of precision and reliability. Hyperbaric welding is commonly employed in offshore oil and gas installations, where the weld quality needs to meet strict safety standards.

Equipment for Underwater Welding

Underwater welding requires specialized equipment to ensure efficient and safe operations. The equipment used varies depending on the type of underwater welding being performed.

Welding Power Source

A reliable welding power source is a crucial component of underwater welding equipment. The power source provides the necessary electric current for the welding process. In underwater welding, portable welding machines are commonly used to ensure ease of mobility and accessibility in various underwater environments. These machines are specifically designed to withstand the challenges presented by the underwater environment, such as corrosion and water pressure.

Electrodes and Filler Materials

Underwater welding electrodes and filler materials are critical in creating solid and durable welds. Specialized waterproof electrodes are utilized in wet welding, allowing for efficient underwater welding operations. These electrodes are designed to provide stable and reliable arc performance in the presence of water. The filler materials used in underwater welding are selected based on the specific application and the characteristics of the welded base metal.

Diving Equipment

Diving equipment is essential for the safety and functionality of underwater welders. This includes a full-face diving mask or helmet, which protects the face and enables efficient communication.

Divers also require a dry or wet suit to protect their bodies from the cold water and potential exposure to contaminants. A buoyancy compensator device (BCD) and diving regulators are also necessary for maintaining proper buoyancy and supplying breathing air during dives.

Hyperbaric Chambers

In hyperbaric welding, specialized hyperbaric chambers are used to create a controlled atmosphere for welding. These chambers are typically constructed to withstand high pressures and are equipped with access hatches and viewing ports.

The chambers are designed to maintain a dry environment during the welding process to ensure the integrity of the welds. Proper training and understanding of hyperbaric chamber operations are essential for welders involved in underwater welding.

Underwater Welding Techniques

Underwater welding techniques involve various processes that welders must be proficient in. These techniques are tailored to the specific challenges of underwater welding and the requirements of different applications.

Shielded Metal Arc Welding (SMAW)

Shielded Metal Arc Welding (SMAW), commonly known as stick welding, is one of the most widely used and versatile underwater welding techniques. It involves the use of a consumable electrode coated in a flux material.

During the welding process, the flux coating melts, creating a protective gas shield around the weld pool, preventing oxidation and ensuring a robust weld. SMAW is suitable for a wide range of welding tasks and can be performed effectively in various underwater environments, from shallow depths to significant depths.

Gas Tungsten Arc Welding (GTAW)

Gas Tungsten Arc Welding (GTAW), also known as Tungsten Inert Gas (TIG) welding, is commonly used in underwater welding applications requiring exceptional precision and control.

GTAW involves using a non-consumable tungsten electrode and a shielding gas to protect the weld pool from contamination. This technique produces high-quality welds with excellent aesthetic appearance and minimal post-weld cleaning. GTAW is often employed in critical welding operations where weld quality is paramount.

Flux-Core Arc Welding (FCAW)

Flux-Core Arc Welding (FCAW) is a semi-automatic welding process commonly used underwater due to its versatility and ease of use.

FCAW utilizes a continuously fed consumable tubular electrode filled with flux. When heated, the flux provides a shielding gas, protecting the weld pool from atmospheric contamination. FCAW is highly suitable for welding thicker sections and can be deployed effectively in various underwater environments.

Plasma Arc Welding (PAW)

Plasma Arc Welding (PAW) is a precise and efficient welding technique in specific underwater applications. PAW involves using a constricted and high-energy plasma arc, which melts the base materials and filler metal.

An inert gas shields The arc from the surrounding atmosphere, ensuring a clean and robust weld. PAW offers excellent control and produces high-quality welds with minimal distortion. It is commonly used in applications that require high accuracy and intricate welds.

Benefits of Underwater Welding

Underwater welding offers several benefits, making it a valuable process for numerous industries and applications. Some key benefits include repairing and maintaining underwater structures without needing dry docking, reduced downtime, and cost efficiency.

Repair and Maintenance of Underwater Structures

Underwater structures like offshore platforms and pipelines require regular maintenance and occasional repairs. Underwater welding allows for the efficient repair and maintenance of these structures without costly dry docking or extensive disassembly.

Repairs can be carried out directly at the site by utilizing underwater welding techniques, including wet welding and hyperbaric welding, saving time and resources.

Reduced Downtime

Traditional welding methods often require structures to be taken out of service for welding operations. This results in significant downtime and disruptions to operations. Underwater welding eliminates the need for dry docking or removal of structures, enabling repairs and maintenance to be carried out without interrupting normal operations. Reduced downtime translates to improved efficiency and cost-saving for industries that rely on continuous operation.

Cost Efficiency

Underwater welding provides cost advantages compared to traditional welding methods. The elimination of dry docking and the ability to perform repairs and maintenance in situ significantly reduce costs associated with dismantling, transportation, and reassembly.

Additionally, underwater welding minimizes the need for skilled labor and specialized equipment for disassembly and reassembly. The overall cost efficiency of underwater welding makes it an attractive choice for industries seeking cost-effective repair and maintenance solutions.

Challenges of Underwater Welding

While underwater welding offers numerous benefits, it also presents several challenges that must be overcome to ensure successful and safe operations. Some key challenges include limited visibility, currents and turbulence, the corrosive environment, and fatigue and decompression sickness risk.

Limited Visibility

Underwater visibility is often reduced due to various factors, such as water clarity, suspended particles, and darkness. Limited visibility poses challenges for underwater welders, making locating and welding joints accurately tricky.

Welders must rely on their training and experience to navigate low-visibility conditions and perform precise welding operations. Using specialized lighting and underwater cameras can also enhance visibility and aid in the welding process.

Currents and Turbulence

Underwater welding is frequently conducted in environments with strong currents and turbulence. These dynamic water conditions can affect the weld pool’s stability and the welding arc’s control.

Welders must have sufficient experience and skill to compensate for the effects of currents and turbulence. Proper positioning, technique adjustment, and the use of welding aids assist in managing these challenges effectively.

Corrosive Environment

The underwater environment is highly corrosive due to saline water and various contaminants. Corrosion can weaken the integrity of welds, leading to potential failures.

Selecting the appropriate materials and electrodes with suitable corrosion resistance for underwater welding is crucial. Applying protective coatings and implementing cathodic protection systems can also help mitigate the corrosive effects and ensure the long-term durability of welds.

Fatigue and Decompression Sickness

Underwater welding operations often require divers to stay submerged at significant depths for extended periods. This can lead to fatigue and increase the risk of decompression sickness.

Proper planning and management of dive times and regular decompression procedures are vital to minimize these risks. Divers must closely monitor their physical condition and adhere to strict safety protocols to ensure their well-being during and after underwater welding operations.

Underwater Welding Applications

Underwater welding finds extensive applications across various industries and sectors due to its unique capabilities. Critical underwater welding sectors include the offshore oil and gas industry, shipbuilding and repairs, civil engineering projects, and hydroelectric power plants.

Offshore Oil and Gas Industry

The offshore oil and gas industry heavily relies on underwater welding to construct and maintain vital infrastructure, such as drilling platforms, pipelines, and underwater structures. Underwater welders play a crucial role in ensuring the structural integrity of these installations by performing regular inspections, repairs, and maintenance. The ability to carry out these operations without requiring structures to be taken out of service is a significant advantage.

Shipbuilding and Repairs

Underwater welding is instrumental in shipbuilding and repairs, allowing for efficient and cost-effective maintenance of ships, submarines, and other marine vessels.

This includes hull repairs, propeller repairs, and the installation of additional structures underwater. Underwater welders are skilled in working with the unique challenges of the dynamic marine environment and ensuring the welded structures’ integrity and safety.

Civil Engineering Projects

Underwater welding is vital in civil engineering projects involving underwater structures, such as bridges, dams, and tunnels. Underwater welders contribute to the construction and maintenance of these structures, ensuring their longevity and safety.

The ability to conduct welding operations underwater saves significant time and resources, as structures can be repaired and maintained without the need for expensive and time-consuming dry docking.

Hydroelectric Power Plants

Hydroelectric power plants rely on underwater welding to construct and maintain various components, such as turbines and penstocks. Underwater welders play a critical role in ensuring the efficiency and reliability of these structures by performing regular inspections and repairs.

Repairs and maintenance can be carried out by utilizing underwater welding techniques without disrupting power plant operations, maximizing productivity and minimizing downtime.

Qualifications and Certifications

To become a proficient underwater welder, obtaining relevant qualifications and certifications is essential. These certifications indicate a welder’s competency and adherence to recognized industry standards.

International Institute of Welding (IIW) Certification

The International Institute of Welding (IIW) offers certifications that validate the competency of welders in various welding techniques, including underwater welding.

These certifications follow international standards and establish the proficiency of underwater welders in specific welding processes and applications. Obtaining IIW certifications demonstrates a welder’s commitment to excellence and ensures compliance with globally recognized welding standards.

American Welding Society (AWS) D3.6M Certification

The American Welding Society (AWS) offers the D3.6M certification, explicitly focusing on underwater welding.

This certification recognizes an individual’s knowledge, skills, and abilities in underwater welding techniques and safety procedures. AWS D3.6M certification is widely recognized in the industry and is a testament to a welder’s expertise in this specialized field.

Diver Welder Certification

In addition to obtaining welding certifications, underwater welders must also hold certifications related to commercial diving. Diver Welder certifications ensure that individuals possess the necessary skills and knowledge to perform welding operations underwater safely.

These certifications encompass diving techniques, decompression procedures, and the ability to work effectively in challenging underwater environments. By holding diver welder certifications, individuals demonstrate their competence in diving and welding.

Future Developments in Underwater Welding

The field of underwater welding continuously evolves with technological advancements, techniques, and safety standards. Several future developments are expected to shape the future of underwater welding.

Automation and Robotics

Automation and robotics are expected to play an increasingly significant role in underwater welding.

Developing automated welding systems and robotic underwater welding devices can enhance productivity, precision, and safety. These advancements will reduce reliance on manual labor, improve efficiency, and expand the capabilities of underwater welders.

Improvement in Equipment and Techniques

Ongoing research and development in underwater welding equipment and techniques will bring further advancements.

This includes the development of more durable and corrosion-resistant welding materials, as well as improved welding power sources and electrodes. Underwater lighting and imaging technology advancements will also enhance visibility and facilitate more accurate welding operations.

Training and Safety Standards

The focus on training and safety standards in underwater welding will likely continue growing.

As the industry recognizes the risks associated with underwater welding, there will be an increased emphasis on comprehensive training programs and updated safety regulations. This commitment to training and safety will ensure that underwater welders are well-prepared to handle the challenges of their profession and minimize risks to their well-being.

Conclusion

Underwater welding is a complex and specialized process that requires careful consideration of safety measures, proper training, and appropriate equipment.

Understanding the different types of underwater welding, equipment requirements, and techniques is crucial for successful underwater welding operations.

While the challenges associated with underwater welding are significant, the benefits, applications, and advancements in this field make it an indispensable process across various industries.

By prioritizing safety, acquiring relevant certifications, and staying updated with advancements, underwater welders can continue to excel in this unique and rewarding profession.