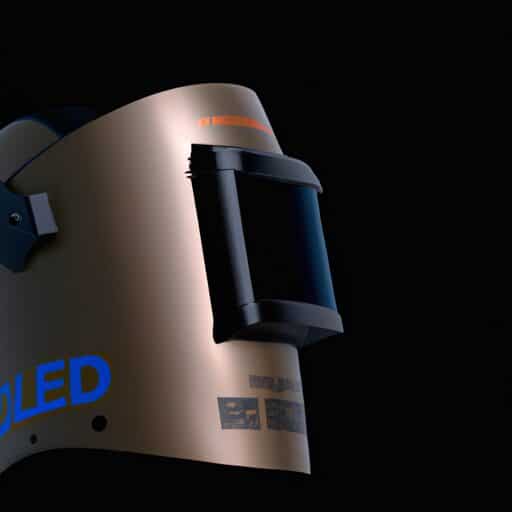

If you’ve ever wondered what the acronym ADF stands for on a welding helmet, we’ve got you covered. ADF, short for Auto-Darkening Filter, is a technology incorporated into modern welding helmets that revolutionizes the welding experience. With its ability to automatically adjust the shade of the helmet’s lens, ADF enhances safety, convenience, and overall productivity for welders. Curious to know more about this innovative feature? Keep reading to discover the fascinating world of ADF and its impact on the welding industry.

What is ADF?

Definition

ADF stands for Auto-Darkening Filter. It is a feature found in welding helmets that automatically adjusts the darkness level of the helmet’s lens in response to the brightness of the welding arc. This ensures that the welder’s eyes are protected from harmful UV and infrared (IR) radiation during the welding process.

Purpose

The primary purpose of ADF is to protect the welder’s eyes from the intense light and radiation produced during welding. Traditional welding helmets have fixed lenses, which require the welder to manually raise and lower the helmet between welds. This can be time-consuming and can increase the risk of eye damage if the helmet is not lowered in time. ADF eliminates the need for manual adjustments, allowing for a more efficient and convenient welding experience.

Components

ADF is comprised of several key components that work together to provide optimal protection for the welder. These components include:

-

Light sensors: These sensors detect the intensity of the welding arc and send a signal to the ADF unit to darken the lens.

-

Liquid crystal display (LCD): The LCD is responsible for changing the lens shade from its default state to a darker shade when the sensors detect a bright arc.

-

UV/IR protection: ADF lenses are designed to filter out harmful ultraviolet (UV) and infrared (IR) radiation, ensuring that the welder’s eyes are shielded from these potentially damaging rays.

How Does ADF Work?

Automatic Darkening

When the welding arc is struck, the light sensors in the ADF detect the sudden increase in brightness. They then send a signal to the LCD, triggering it to darken the lens to a shade that is appropriate for the welding process being performed. This automatic darkening process happens within milliseconds, offering seamless protection for the welder’s eyes.

Light Sensors

The light sensors in the ADF are strategically positioned in the helmet to effectively measure the intensity of the welding arc. These sensors are highly sensitive and can accurately detect the changes in brightness, allowing for precise control of the lens shade. By constantly monitoring the welding environment, the sensors ensure optimal eye protection at all times.

UV/IR Protection

One of the key functions of ADF is to provide protection against harmful UV and IR radiation. The ADF lens is specifically designed to filter out these types of radiation, preventing them from reaching the welder’s eyes. This is crucial, as prolonged exposure to UV and IR rays can cause significant eye damage, such as photokeratitis (welder’s flash) and cataracts. With ADF, welders can work confidently knowing that their eyes are shielded from these risks.

Advantages of ADF

Improved Efficiency

One of the major advantages of ADF is its ability to enhance efficiency during the welding process. With a fixed lens helmet, welders would need to manually flip the helmet up and down between welds, interrupting their workflow. ADF eliminates this constant helmet movement, allowing welders to work continuously without any interruptions. This ultimately leads to greater productivity and faster completion of welding projects.

Saves Time and Effort

By removing the need for manual adjustments, ADF saves welders valuable time and effort. Instead of wasting precious seconds flipping the helmet, welders can focus solely on their work. This time-saving aspect is particularly beneficial in time-sensitive welding tasks or when welders are working on large projects that require uninterrupted concentration. ADF streamlines the welding process, making it more efficient and less physically demanding.

Enhanced Safety

The most important advantage of ADF is the enhanced safety it provides to welders. Since ADF automatically adjusts the lens shade, it ensures that the welder’s eyes are constantly protected from the intense light and radiation produced during welding. This reduces the risk of eye injuries, such as arc eye or welder’s flash, which can cause extreme discomfort and temporary vision impairment. By safeguarding their vision, ADF promotes long-term eye health for welders.

Different ADF Modes

Welding Mode

The welding mode is the primary mode of ADF and is used during welding operations. In this mode, the lens darkens to the appropriate shade level to protect the welder’s eyes from the intense light and radiation produced by the welding arc. The specific shade level can be adjusted based on the welding process and the welder’s comfort.

Grinding Mode

ADF also includes a grinding mode, which is specifically designed for grinding and cutting operations. In this mode, the lens remains clear, allowing the welder to have an unobstructed view of the workpiece. This is essential for precision work, as it enables the welder to accurately see the grinding or cutting point.

Cutting Mode

Some advanced ADF models offer a cutting mode, which is optimized for plasma cutting and similar processes. This mode provides a slightly darker shade compared to grinding mode but not as dark as welding mode. It offers adequate protection for the eyes while allowing the welder to clearly see the cutting point.

Choosing the Right ADF for You

Variable Shade

One of the key factors to consider when choosing an ADF is the variable shade range it offers. The shade range determines the darkness level of the lens when the welding arc is struck. Different welding processes require different shades, so it’s important to choose an ADF that can provide the appropriate shade for your specific welding needs. A broader shade range offers greater versatility and adaptability to different welding applications.

Reaction Time

Another crucial factor to consider is the ADF’s reaction time. Reaction time refers to how quickly the lens darkens once the welding arc is detected. A faster reaction time is desirable, as it ensures instant eye protection and minimizes the risk of exposure to harmful light and radiation. Look for an ADF with a reaction time of 1/20,000th of a second or faster for optimal protection.

Sensitivity Adjustment

ADF should also have sensitivity adjustment capabilities. Different welding environments can vary in terms of light intensity, so it’s important to have the ability to adjust the ADF’s sensitivity. This allows welders to fine-tune the ADF’s response to different lighting conditions and ensure consistent and reliable eye protection.

Care and Maintenance of ADF

Cleaning

To maintain the efficiency and longevity of ADF, regular cleaning is essential. Start by removing any dust or debris from the helmet, paying special attention to the lens area. Use a soft cloth or specialized lens cleaning wipes to gently wipe the lens, ensuring that no smudges or residue remain. Avoid using abrasive materials or harsh cleaners, as they can scratch or damage the lens. Regular cleaning helps to ensure clear visibility and uninterrupted functionality of the ADF.

Replacement

Over time, the ADF lens may become scratched or damaged, compromising its effectiveness. It’s important to regularly inspect the lens for any signs of wear and tear. If the lens is significantly scratched or damaged, it should be replaced promptly. Most ADF helmets offer replaceable lenses, making it easy to maintain optimal eye protection. Follow the manufacturer’s instructions for proper lens replacement to ensure the ADF continues to function effectively.

Battery Replacement

Many ADF helmets are powered by batteries to operate the automatic darkening feature. It is important to regularly check the battery status and replace them as needed. Low batteries can result in slower reaction times or even failure of the ADF. Follow the manufacturer’s instructions for battery replacement and ensure that fresh batteries are always available to ensure consistent and reliable eye protection.

Common FAQs about ADF

Is ADF necessary?

While ADF is not mandatory, it is highly recommended for any welding operation. ADF provides crucial eye protection by automatically adjusting the lens shade, reducing the risk of eye injuries caused by bright welding arcs. Investing in an ADF helmet demonstrates a commitment to safety and promotes long-term eye health for welders.

Can ADF be used for other purposes?

While ADF is primarily designed for welding, it can be used for other applications that involve exposure to intense light and radiation. For example, some ADF helmets can be used for plasma cutting or brazing. However, it’s important to note that not all ADF models are suitable for these alternate applications. Always check the manufacturer’s specifications to ensure compatibility for specific tasks.

Is ADF compatible with different welding processes?

Yes, ADF is compatible with various welding processes, including MIG, TIG, stick welding, and flux-cored arc welding. The variable shade range and sensitivity adjustment capabilities of ADF allow for adaptability to different welding conditions. However, it’s important to choose the right ADF with appropriate shade range and reaction time for your specific welding process to ensure optimal eye protection.

Conclusion

In conclusion, ADF (Auto-Darkening Filter) is a crucial feature found in welding helmets that provides automatic darkening of the lens to protect the welder’s eyes. It offers improved efficiency, time savings, and enhanced safety during the welding process. ADF has different modes, such as welding, grinding, and cutting, to cater to specific tasks. When choosing an ADF, factors like variable shade, reaction time, and sensitivity adjustment should be considered. Proper care and maintenance, including regular cleaning, lens replacement, and battery replacement, are essential to ensure optimal performance. While ADF is primarily used for welding, it can also be used for other applications that involve exposure to intense light and radiation. Overall, ADF is a valuable tool for welders, providing reliable eye protection and promoting long-term eye health.