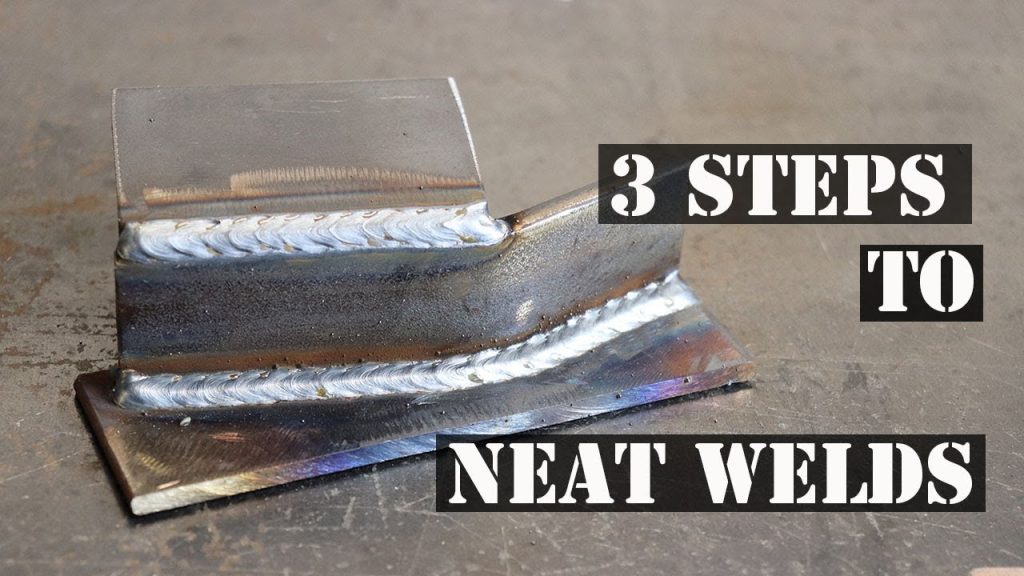

If you’ve ever wondered how to improve the appearance of your welds, you’re not alone. Whether you’re a beginner or an experienced welder, achieving visually pleasing welds can be challenging.

But fear not, as this article will provide you with practical tips and techniques to enhance the aesthetics of your welds. From selecting the correct welding settings to mastering the proper technique, this guide will help you take your welds from functional to impressive.

Get ready to take your welding skills to the next level and create welds that hold strong and look great.

Choosing the Right Welding Method

Choosing the correct method is crucial for achieving successful and aesthetically pleasing results when it comes to welding. Consider the material you will work with; different welding methods are better suited for specific materials.

For example, gas metal arc welding (GMAW) is commonly used for steel and aluminum, while tungsten inert gas welding (TIG) is often preferred for stainless steel and other non-ferrous metals.

Consider the Material

Before deciding on a welding method, it is essential to consider the material you will be working with. Each material has its unique properties, such as melting point and conductivity, which can influence the welding method that would work best.

Researching and consulting with professionals or experienced welders can help you determine the most suitable technique for your material.

Assess the Thickness

Another factor to consider when choosing a welding method is the thickness of the material. Some welding methods, such as TIG welding, are better suited for thinner materials as they provide more precise control over the heat input. On the other hand, methods like shielded metal arc welding (SMAW) or stick welding are often used for thicker materials due to their ability to provide deeper penetration.

Evaluate the Joint Type

The type of joint you will be welding is also essential in determining the appropriate welding method. Different joint types, such as butt joints, lap joints, or fillet joints, require specific welding techniques to achieve high-quality and visually appealing welds. Researching the different joint types and consulting with professionals can help you make an informed decision on the welding method that would be most suitable for your specific joint type.

Preparing the Welding Surface

Properly preparing the welding surface is crucial for achieving solid and visually pleasing welds. Following a few key steps, you can ensure that the surface is clean, contaminant-free, and properly aligned.

Clean the Metal

Before beginning the welding process, cleaning the metal surface thoroughly is essential. Any dirt, grease, or debris on the surface can negatively impact the quality of the weld. Remove any contaminants from the metal surface using a wire brush or sandpaper to ensure a clean and smooth welding surface.

Remove Any Rust or Paint

In addition to cleaning the metal surface, removing any rust or paint that may be present is essential. Rust or paint can interfere with welding, leading to poor adhesion and weak welds. Utilize a wire brush, grinder, or chemical solutions specifically designed for rust removal to eliminate rust or paint before welding.

Ensure Proper Alignment

For successful welding, it is crucial to ensure that the joined pieces are correctly aligned. Misalignment can result in an uneven weld and compromise the structural integrity of the joint. Take the necessary steps to ensure that the pieces are aligned correctly before initiating the welding process. Depending on the specific welding project, This may involve clamps, fixtures, or other alignment tools.

Choosing the Correct Electrode or Filler Metal

The correct electrode or filler metal is vital for achieving robust and visually appealing welds. The electrode or filler metal must be compatible with the base metal and the welding method.

Match the Electrode to the Base Metal

Choosing an electrode compatible with the base metal is crucial for achieving solid and reliable welds. The electrode should have similar properties to the base metal, such as tensile strength and chemical composition, to ensure proper fusion and minimize the risk of defects. Conduct thorough research or consult with professionals to determine which electrode best suits your base metal.

Consider the Welding Position

Different welding positions, such as flat, horizontal, vertical, or overhead, require specific characteristics in an electrode or filler metal. Some electrodes may perform exceptionally well in a flat or horizontal position but struggle in vertical or overhead positions. Consider the welding position you will be working in and select an electrode or filler metal designed for optimal performance.

Choose the Right Size and Type

When selecting an electrode or filler metal, choosing the appropriate size and type is essential. The electrode or filler metal size should be compatible with the thickness of the material you are welding. Using an electrode or filler metal that is too small can result in inadequate penetration, while using one that is too large may lead to excessive heat buildup and distortion. Additionally, consider the type of electrode or filler metal that would work best for your specific welding project, whether a coated electrode, flux-cored wire, or solid wire.

Establishing the Right Welding Technique

Developing and implementing the proper welding technique is essential for achieving consistent, high-quality welds. By focusing on the critical aspects of arc length, travel speed, and angle, you can ensure the success of your welding project.

Maintain the Right Arc Length

Maintaining the right arc length is crucial for achieving robust and visually appealing welds. The arc length refers to the distance between the electrode and the workpiece. Keeping the arc length consistent allows for proper heat control and fusion. Too short of an arc length can cause the electrode to stick to the workpiece, while too long can result in a weak and porous weld. Practice maintaining a consistent arc length to achieve optimal welding results.

Control the Travel Speed

Controlling the travel speed is another important consideration when establishing the proper welding technique. The travel speed refers to how quickly the welder moves along the joint. Moving too quickly can lead to insufficient fusion and weak welds while moving too slowly can result in excessive heat input and distortion. Find the right balance by practicing with different travel speeds and paying attention to the appearance and quality of the weld bead.

Use the Correct Angle

Using the correct angle while welding is crucial for achieving proper penetration and weld profile. The angle refers to the orientation of the electrode relative to the workpiece. The angle can vary depending on the welding method and the joint type. Properly adjusting the angle can ensure adequate fusion and reduce the likelihood of defects. Experiment with different angles and consult professionals to determine the optimal angle for your specific welding project.

Monitoring Welding Parameters

To ensure consistent and high-quality welds, monitoring and controlling various welding parameters is essential. Key parameters to focus on include heat input, voltage and current, and weld pool size.

Control Heat Input

Controlling heat input is crucial for achieving the desired results in welding. Excessive heat can lead to distortion, while insufficient heat can result in inadequate fusion and weak welds. Adjusting the welding parameters and maintaining the appropriate heat input can optimize the welding process and produce high-quality welds. Pay attention to the welded material, as different materials require different heat input levels.

Optimize Voltage and Current

The voltage and current settings play a significant role in the welding process. These settings determine the heat generated by the welding arc. Optimizing the voltage and current can help achieve the desired weld penetration and fusion. Experiment with different voltage and current settings to find the optimal combination for your welding project.

Monitor the Weld Pool Size

Monitoring the size of the weld pool is essential for controlling the quality of the weld. A weld pool that is too large can lead to excessive heat input, distortion, and insufficient fusion. Conversely, a weld pool that is too small may result in weak and porous welds—practice monitoring and adjusting the welding parameters to maintain the appropriate weld pool size throughout the welding process.

Ensuring Proper Joint Preparation

Proper joint preparation is crucial for achieving robust and visually appealing welds. By taking the necessary steps to bevel or cut the joint edges, remove contaminants, and use proper clamping and fixturing, you can ensure the success of your welding project.

Beveling or Cutting the Joint Edges

Beveling or cutting the joint edges is often necessary for proper penetration and fusion. Beveling involves cutting a sloped edge on the joint, allowing for a wider welding area and more excellent fusion. This is particularly important for thicker materials or when working with certain joint types. Take the time to properly bevel or cut the joint edges to ensure optimal weld quality.

Removing Any Contaminants

Before welding, removing any contaminants from the joint surfaces is crucial. Contaminants such as dirt, oil, or grease can negatively impact the quality of the weld, leading to porosity, weak fusion, and other defects. Thoroughly clean the joint surfaces using appropriate cleaning methods and materials to ensure a clean and uncontaminated welding surface.

Using Proper Clamping and Fixturing

Properly clamping and fixturing the joint is essential for maintaining alignment and achieving solid welds. Securely holding the joint in place with clamps, fixtures, or other holding devices minimizes the risk of misalignment during welding. This ensures the weld is consistent, visually appealing, and structurally sound. Take time to properly position and clamp the joint before beginning welding.

Applying Suitable Welding Accessories

Using suitable welding accessories can significantly enhance the quality of your welds and ensure your safety. Consider incorporating water-cooled systems, tungsten grinders for TIG welding, and welding helmets with good visibility into your welding setup.

Using Water-Cooled Systems

Water-cooled systems can help regulate the temperature of your welding torch or electrode holder, preventing overheating and extending their lifespan. By dissipating excess heat, water-cooled systems can also improve weld quality and reduce the risk of distortions. Consider investing in a water-cooling system compatible with your welding equipment for improved welding performance.

Using Tungsten Grinders for TIG Welding

Investing in a tungsten grinder can significantly enhance your welding results if you frequently work with TIG welding. Tungsten grinders ensure that the tungsten electrode maintains a precise and clean tip, which improves arc stability and weld quality. By adequately preparing the tungsten electrode, you can better control the TIG welding process and produce aesthetically pleasing welds.

Using Welding Helmets with Good Visibility

Protecting your eyes and face during welding is essential for your safety. Using a welding helmet with good visibility ensures you can see the welding area and maintain better control over the welding process. Look for helmets with high-quality lenses that provide excellent optical clarity and protection against harmful ultraviolet and infrared radiation. Investing in a welding helmet with good visibility can significantly improve your welding technique and overall welding experience.

Practicing Welding Technique and Control

Practicing welding technique and control is essential for improving your skills and achieving high-quality welds. You can enhance your welding abilities by using scrap materials, mirrors or cameras for better visibility, and managing spatter and weld pool fluidity.

Practice on Scrap Materials

To enhance your welding technique, consider practicing scrap materials before tackling essential projects. This allows you to familiarize yourself with different welding methods, adjust your settings, and fine-tune your technique without the pressure of producing a perfect weld. With practice, you can gain confidence, improve your control, and make your welds look better.

Use a Mirror or Camera for Better Visibility

It can be challenging to see the welding area clearly, especially when working on complex joints or tight spaces. Using a mirror or camera can provide an alternative perspective, improving visibility and ensuring precise control over the welding process. Place a mirror strategically or use a camera with a screen or live feed to monitor your progress and adjust accordingly.

Control Spatter and Weld Pool Fluidity

Spatter and excessive weld pool fluidity can negatively affect the appearance and quality of your welds. Excessive spatter can lead to welding defects and require additional cleanup, while overly fluid weld pools can result in weak and porous welds. Adjusting parameters such as arc length, voltage, and travel speed can help minimize spatter and control the fluidity of the weld pool. Practice controlling these parameters and experiment with different techniques to achieve cleaner and more controlled welds.

Post-Welding Processes and Finishing

After completing the welding process, there are additional steps you can take to improve the appearance of your welds. Removing welding slag, cleaning the weld area, and performing post-weld heat treatment, if required, are essential finishing touches.

Removing Welding Slag

Welding slag is the residue that forms on the surface of the weld after welding. It can be removed using a chipping hammer, wire brush, or other tools. Removing welding slag not only enhances the appearance of the weld but also allows for better inspection of the weld bead and ensures a smooth and clean surface.

Cleaning the Weld Area

In addition to removing welding slag, cleaning the surrounding weld area is crucial for achieving visually appealing results.

Use appropriate cleaning methods and materials to remove contaminants from the weld area, such as dust, debris, or spatter. This will help showcase the weld and improve the overall aesthetic appearance.

Performing Post-Weld Heat Treatment if Required

In some cases, post-weld heat treatment may be necessary to relieve residual stresses and improve the mechanical properties of the weld.

Post-weld heat treatment typically involves subjecting the weld to controlled heating and cooling cycles. Consult professionals or refer to welding codes and standards to determine if post-weld heat treatment is recommended for your specific application.

Seeking Advice from Professionals

Even with comprehensive knowledge and understanding of welding techniques, seeking advice and guidance from professionals can significantly benefit your welding journey.

By attending welding workshops or training sessions, consulting experienced welders and joining online welding communities; you can learn from the experiences of others and gain valuable insights.

Attend Welding Workshops or Training

Attending welding workshops or training sessions can provide you with hands-on experience, exposure to different welding techniques, and the opportunity to learn from industry experts.

These workshops often cover a wide range of topics and allow for practical application of welding principles. Consider enrolling in local welding workshops or online training programs to enhance your skills further and connect with fellow welders.

Consult Experienced Welders

Experienced welders can provide valuable insights and guidance based on their years of practical experience.

Reach out to experienced welders in your community or network and ask for their advice on specific welding techniques or challenges you may be facing. Their expertise and mentorship can help you overcome obstacles, refine your techniques, and make your welds look even better.

Join Online Welding Communities

Online welding communities provide platforms for connecting with fellow welders worldwide.

These communities offer opportunities to share knowledge, ask questions, and receive feedback on your welding projects. Participating in online discussions and seeking advice from community members can broaden your perspective, help you troubleshoot welding issues, and foster connections within the welding community.

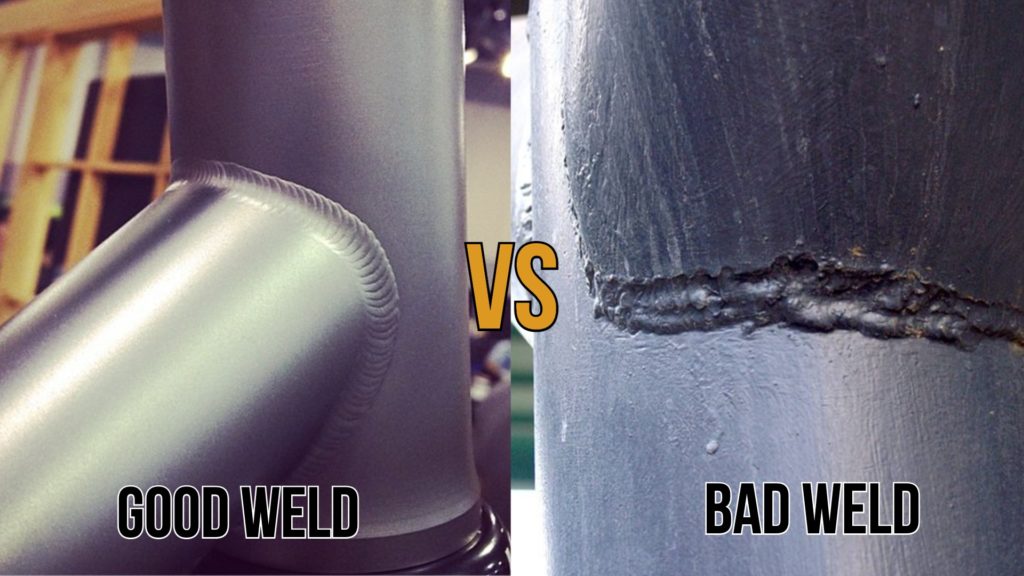

In conclusion, making your welds look better requires careful consideration of various factors such as material selection, joint preparation, electrode choice, welding technique, and post-welding processes.

By following the outlined steps and seeking guidance from professionals, you can continually improve your welding skills, resulting in stronger and visually appealing welds. Remember to practice, experiment, and never stop learning on your journey to becoming a skilled welder.