Are you curious about the right size of welding clamps for your projects? Well, fret not! In this article, we’ll guide you through selecting the perfect size of welding clamps. Whether you’re a seasoned welder or starting, we’ve got you covered.

So, let’s dive in and explore the factors you need to consider for a snug fit and secure welding!

Factors to Consider

When choosing the right size of welding clamps, there are several factors that we need to take into consideration. These factors will help us determine the appropriate clamp size for our project and ensure we achieve secure and effective welds.

Type of Project

The first factor to consider is the type of project we are working on. Different projects require different clamp sizes depending on the size and complexity of the welds. For example, we may only need smaller clamps if we work on a small-scale project with thin materials. On the other hand, more significant projects with thicker materials will require larger clamps to provide adequate clamping force.

Material Thickness

Material thickness is crucial in determining the size of welding clamps we should use. Thicker materials require clamps with a broader opening capacity to accommodate the thickness. Using too small clamps for the material thickness can result in inadequate clamping force, leading to poor welding quality or joint failure. Thus, measuring the material thickness and selecting clamps with matching capacity is essential.

Joint Configuration

The joint configuration is another factor affecting the welding clamp size choice. Different joint configurations require different clamping techniques and clamp sizes. For example, a corner joint may require larger clamps to secure the materials at the desired angle, while a T-joint may need a narrower jaw to hold the pieces together. Understanding the joint configurations will help us determine the appropriate clamp size for each situation.

Clamp Design

The design of the welding clamp is an important consideration when selecting the correct size. Different clamp designs are available, each with unique features and advantages. Some standard clamp designs include C-clamps, locking pliers, toggle clamps, and magnetic clamps. The choice of clamp design should depend on the project’s specific requirements, such as the accessibility of the joint, the need for adjustable clamping force, or the ability to hold materials securely in place. By selecting the right clamp design, we can ensure efficient and effective clamping during welding.

Available Space

The available space in our workspace also influences the selection of welding clamp sizes. If we have limited space, choosing clamps that fit well and maneuvered quickly within the restricted area is essential. Conversely, larger clamps may be more suitable to provide a secure grip on the materials if we have a spacious workspace. The available space will help us optimize our work area and make welding operations more convenient.

Understanding Welding Clamps

Before diving into the factors that determine the right size of welding clamps, it is essential to understand the definition and purpose of welding clamps.

Definition and Purpose

Welding clamps are tools that are specifically designed to hold and secure materials together during the welding process. They provide the necessary clamping force to keep the pieces in place, ensuring precise alignment and preventing movement or distortion during welding. Welding clamps are crucial for maintaining joint stability and achieving high-quality welds. They come in various sizes and designs to cater to different project requirements.

Types of Clamps

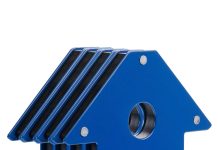

Several types of welding clamps are available, each with its advantages and applications. Joint clamps include C-clamps, locking pliers, corner clamps, magnetic clamps, and toggle clamps. C-clamps are versatile and widely used, providing a good balance between strength and flexibility, and locking pliers, also known as Vise-Grips, feature adjustable jaw openings, and locking mechanisms, allowing for easy and quick clamping. Corner clamps are designed to hold materials at a precise right angle, making them ideal for corner joint welding. Magnetic clamps use magnetism to hold materials together securely, while toggle clamps provide a quick and efficient method of clamping using a lever mechanism. Understanding the different types of clamps will help us choose the most suitable one for our specific project needs.

Type of Project

To choose the right size of welding clamps, we need to consider the requirements of our project carefully.

Determining Project Requirements

Before selecting the appropriate clamp size, we need to understand the specific requirements of our project. This includes assessing the welds’ size, the materials’ dimensions, and any unique considerations that may affect the clamping process. By evaluating these requirements, we can determine the overall scope and complexity of the project, which will guide us in selecting the proper size of welding clamps.

Identifying Clamp Size

Once we have determined the requirements of our project, we can proceed to identify the appropriate clamp size. The maximum opening capacity of the jaws typically specifies the clamp size. This measurement determines the maximum thickness of the materials that the clamp can accommodate. By measuring the thickness of our materials and selecting a clamp size that matches or slightly exceeds this measurement, we can ensure a proper fit and optimal clamping force. It is important to note that choosing a clamp size that is too small may result in inadequate clamping force, while choosing a clamp size that is too large may cause unnecessary bulkiness or difficulty maneuvering the clamp.

Material Thickness

The thickness of the materials we are working with is crucial in determining the size of welding clamps we should use.

Impacts on Clamp Size

Thicker materials require clamps with a broader opening capacity to hold them securely securely. When selecting clamps, it is essential to consider the maximum thickness the jaws can accommodate. If the materials are too thick for the clamps, they will not provide sufficient clamping force, and the weld may be compromised. Choosing clamps with a slightly larger capacity than the material thickness is advisable to ensure a secure and stable grip.

Matching Material Thickness to Clamp Capacity

To ensure a proper fit, matching the material thickness to the clamp capacity is essential. This can be done by accurately measuring the thickness of the materials and selecting clamps with corresponding maximum opening sizes. For instance, if we are working with materials that are 1/4 inch thick, we should choose clamps that can accommodate this thickness comfortably. We can achieve effective clamping and produce high-quality welds by ensuring a proper match between material thickness and clamp capacity.

Joint Configuration

The joint configuration plays a significant role in determining the size of welding clamps required for a project.

Types of Joints

Welding joints come in various configurations, each with unique characteristics and requirements. Common types of joints include butt joints, corner joints, lap joints, T-joints, and edge joints. Each joint configuration requires different clamping techniques and sizes to ensure proper alignment and stability during welding. Understanding the different joint configurations will help us select the appropriate clamp size for each joint type.

Choosing Clamp Size for Different Joint Configurations

When choosing the right clamp size for different joint configurations, it is essential to consider the specific requirements of each joint type. For example, a corner joint requires clamps that can securely hold the materials at a right angle, while a butt joint may require larger clamps to hold the materials in line with each other. We can select the appropriate clamp size to ensure precise alignment and stability during welding by carefully assessing the joint configuration and its unique demands.

Clamp Design

The design of welding clamps is critical when selecting the right size for our project.

Different Clamp Designs

Various clamp designs are available, each offering advantages and suitability for different applications. Some standard clamp designs include C-clamps, locking pliers, toggle, corner, magnetic, and parallel clamps. Each design has unique features and mechanisms determining its clamping force, adjustability, and compatibility with different projects. It is essential to understand the characteristics of each clamp design to make an informed decision when choosing the right size.

Choosing the Right Clamp Design for the Job

When choosing the right clamp design, we need to consider the specific requirements of our project. Factors such as joint accessibility, desired clamping force, adjustability, and ease of use should all be considered. For example, a C-clamp or locking pliers may be the most suitable options if we have limited space or need to work in tight corners. On the other hand, for projects requiring a quick and efficient clamping process, toggle clamps or magnetic clamps can offer significant advantages. By understanding the strengths and limitations of each clamp design, we can select the one that best meets our project’s needs.

Available Space

The available workspace is essential in determining the size of welding clamps that should be used.

Considering Workspace Limitations

Before selecting the clamp size, assessing the available space in our workspace is crucial. If we have limited space, we must choose clamps that fit well within the confined area and offer ease of maneuverability. Large clamps may be cumbersome and restrict our ability to work efficiently. Considering the workspace limitations, we can select clamps to optimize our work area and allow for smooth and effective welding operations.

Selecting Clamps that Fit Well in the Workspace

Based on the available space, we can select welding clamps that fit well and provide optimum functionality within the workspace. Compact clamps or clamps with adjustable components can be beneficial when space is limited. Additionally, considering the ergonomics of the clamps, such as their handles and weight distribution, can contribute to a comfortable and user-friendly experience. By choosing clamps that fit well in the workspace, we can maximize our productivity and achieve better results in our welding projects.

Clamp Capacity and Strength

Determining the required clamp capacity and ensuring sufficient strength is essential for successful welding operations.

Determine Required Clamp Capacity

To determine the required clamp capacity, we must consider the thickness and material type of the joined pieces. By measuring the thickest part of the materials, we can ascertain the maximum opening size that the clamps need to accommodate. Choosing clamps with a capacity equal to or slightly larger than the maximum material thickness is crucial to ensure a secure grip and adequate clamping force. Failing to choose clamps with the correct capacity can lead to joint instability and compromised weld quality.

Ensuring Sufficient Strength for the Job

In addition to determining the required clamp capacity, we must ensure that the clamps are strong enough to withstand the forces exerted during welding. Choosing clamps with sufficient strength is particularly important when working with heavy or bulky materials. The clamps must handle the weight and stress without deforming or losing grip. By selecting clamps with a suitable strength rating, we can ensure that they will effectively hold the materials in place throughout the welding process, resulting in solid and durable welds.

Budgetary Constraints

Budgetary considerations are another essential aspect when choosing the right size of welding clamps.

Finding the Right Balance

While investing in high-quality welding clamps is essential, budget constraints may require us to balance cost and functionality. It is advisable to prioritize clamps that meet the specific requirements of our project while staying within our budget. Considerations such as the frequency of use, durability, and performance of the clamps should be weighed against the cost. We can make informed decisions that meet our project needs and financial limitations by carefully assessing the value and cost-effectiveness of different options.

Considering Cost-Effective Options

When working within a budget, exploring cost-effective options for welding clamps may be beneficial. This could include purchasing clamp sets or bundles that offer multiple clamps at a discounted price or considering second-hand or refurbished clamps that are still in good working condition. Additionally, researching different brands and comparing prices can help us identify affordable yet reliable options. By considering cost-effective alternatives, we can ensure that we acquire the necessary welding clamps without compromising quality or performance.

Ergonomics and Comfort

The ergonomics and comfort of welding clamps are essential for a pleasant and efficient working experience.

Choosing Clamps that Provide Comfort and Ease of Use

Working with cumbersome or uncomfortable clamps can affect our productivity and lead to fatigue and strain on our hands and wrists. Choosing clamps that provide ergonomic features such as comfortable handles, non-slip grips, or mechanisms that reduce hand fatigue is advisable. Clamps with user-friendly adjustments or quick-release mechanisms can also contribute to a smoother clamping process. By prioritizing comfort and ease of use, we can enhance our overall workflow and positively impact the quality of our welds.

Evaluating Grip Strength

The grip strength of welding clamps is crucial to ensure the secure and stable clamping of materials. Clamps with a high grip strength will firmly hold the materials in place, preventing any movement or misalignment during welding. It is essential to evaluate the grip strength of the clamps under consideration to ensure they are suitable for the specific requirements of our project. This can be achieved by researching the clamp’s specifications, reading user reviews, or even physically testing the clamps before making a final decision.

In conclusion, choosing the right size of welding clamps is a critical decision that can significantly impact the quality and success of a welding project. By considering factors such as the type of project, material thickness, joint configuration, clamp design, available space, clamp capacity, budgetary constraints, and ergonomic considerations, we can make informed choices that ensure optimal clamping force and performance. T

Evaluating these factors and selecting the appropriate welding clamps will result in secure, precise, and high-quality welds, making our welding projects successful.