You’re ready to tackle your next welding project, but now you’re faced with the dilemma of choosing the right welding wire. With so many options available, it’s easy to feel overwhelmed. But fear not! In this article, we’ll guide you through the process of selecting the perfect welding wire for your needs, ensuring that your welds turn out strong and flawless every time. From understanding the different types of welding wires to considering factors like material compatibility and wire diameter, we’ve got you covered. So grab your welding helmet and let’s get started on this wire-choosing adventure!

1. Understand the Types of Welding Wire

When it comes to welding, one of the most important factors to consider is the type of welding wire you will use. There are various types of welding wire available, each with its own unique properties and characteristics. Understanding these types will help you choose the best wire for your specific welding project.

1.1 Carbon Steel Welding Wire

Carbon steel welding wire is one of the most commonly used types of welding wire. It is suitable for a wide range of applications and is known for its strength and durability. This type of wire is ideal for welding carbon steel materials and is often used in general construction and automotive industries.

1.2 Stainless Steel Welding Wire

Stainless steel welding wire is specifically designed for welding stainless steel materials. It contains a higher percentage of chromium, which gives it excellent corrosion resistance. This type of wire is commonly used in the food and beverage industry, as well as in applications where resistance to rust and corrosion is critical.

1.3 Aluminum Welding Wire

Aluminum welding wire is specially formulated for welding aluminum and aluminum alloys. It has a higher melting point than other types of welding wire and requires specialized equipment for proper welding. This type of wire is frequently used in the aerospace and automotive industries, where aluminum components are common.

1.4 Flux-Cored Welding Wire

Flux-cored welding wire is a type of wire that contains a flux core, which provides a shielding gas when heated. It is commonly used in applications where a separate shielding gas is not available or practical. Flux-cored wire is suitable for welding thicker materials and is often used in heavy fabrication and structural welding.

1.5 Nickel Alloy Welding Wire

Nickel alloy welding wire is designed for welding specific nickel alloys, such as Inconel and Monel. These alloys are known for their high temperature and corrosion resistance. Nickel alloy wire is commonly used in industries such as aerospace, chemical processing, and power generation.

1.6 Copper Alloy Welding Wire

Copper alloy welding wire is used for welding copper and copper alloys. It is known for its excellent electrical conductivity and thermal conductivity. This type of wire is commonly used in electrical and plumbing applications, as well as in the manufacturing of various copper-based products.

1.7 Titanium Welding Wire

Titanium welding wire is specifically formulated for welding titanium and titanium alloys. Titanium is a lightweight and corrosion-resistant metal that is commonly used in aerospace, marine, and medical applications. Titanium welding wire requires specialized equipment and expertise due to the unique properties of titanium.

1.8 Cast Iron Welding Wire

Cast iron welding wire is designed for welding cast iron materials, which can be challenging due to the brittle nature of cast iron. This type of wire contains additives that help prevent cracking and ensure proper fusion. Cast iron welding wire is commonly used for repairing or fabricating cast iron components.

1.9 Magnesium Welding Wire

Magnesium welding wire is used for welding magnesium and magnesium alloys. Magnesium is a lightweight metal with excellent strength-to-weight ratio, making it suitable for applications where weight reduction is critical. Magnesium welding wire requires specialized equipment due to the unique properties of magnesium.

1.10 Tungsten Inert Gas (TIG) Welding Wire

TIG welding wire, also known as GTAW (Gas Tungsten Arc Welding) wire, is commonly used in TIG welding processes. It is available in various materials, such as carbon steel, stainless steel, and aluminum. TIG welding wire provides precise and high-quality welds, making it suitable for applications where aesthetics and precision are important.

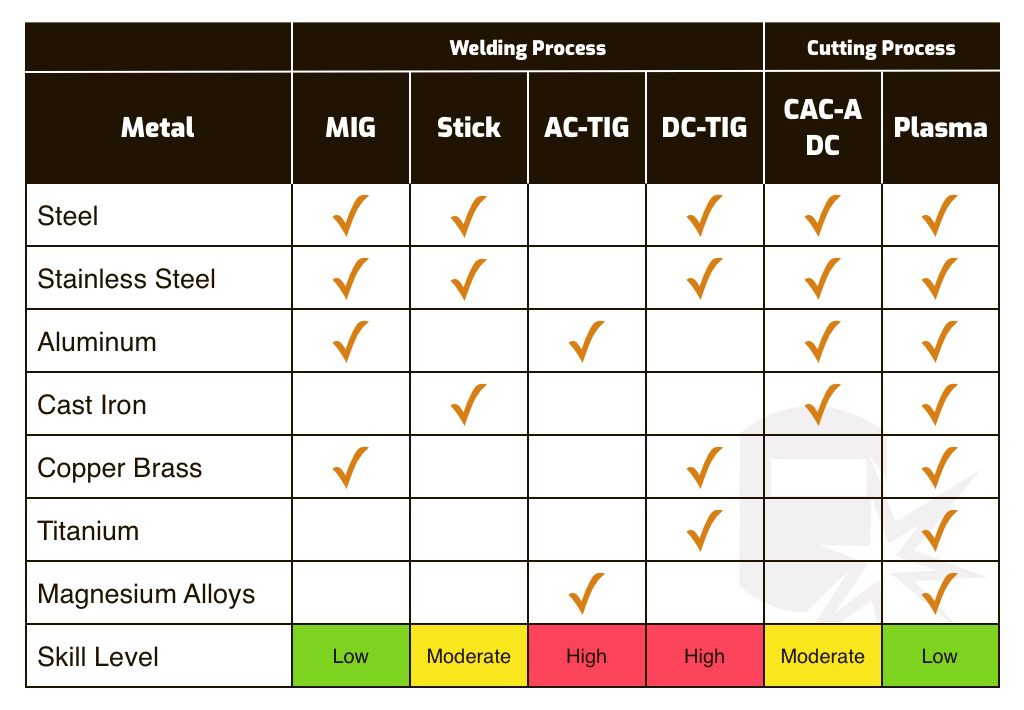

2. Consider the Welding Process

Once you have determined the type of welding wire that is suitable for your application, the next step is to consider the welding process itself. Different welding processes have specific requirements that must be taken into account when choosing welding wire.

2.1 Stick Welding

Stick welding, also known as Shielded Metal Arc Welding (SMAW), is one of the most common welding processes. It uses a consumable electrode coated in flux to create the weld. When choosing welding wire for stick welding, it is important to select a wire that is compatible with the specific electrode used in the process.

2.2 MIG Welding

MIG welding, also known as Gas Metal Arc Welding (GMAW), is a popular welding process that uses a continuous solid wire electrode and a shielding gas to create the weld. When choosing welding wire for MIG welding, it is crucial to consider the material being welded and the required tensile strength and ductility.

2.3 TIG Welding

TIG welding, as mentioned earlier, uses TIG welding wire in the form of a tungsten electrode. It does not require a consumable wire, but rather uses a separate filler material if needed. When choosing TIG welding wire, it is important to consider the material being welded and the desired weld quality, as TIG welding provides precise and high-quality welds.

2.4 Flux-Cored Arc Welding

Flux-Cored Arc Welding (FCAW) is a welding process that uses a hollow wire with flux in its core. The flux provides a shielding gas when heated, eliminating the need for an external shielding gas. When selecting welding wire for FCAW, it is necessary to choose a wire that is appropriate for the specific application and desired weld quality.

2.5 Submerged Arc Welding

Submerged Arc Welding (SAW) is a welding process that uses a granular flux and a continuous wire electrode to create the weld. The electrode is submerged in the flux, hence the name of the process. When selecting welding wire for SAW, it is important to consider the material being welded, the desired weld quality, and the characteristics of the flux being used.

3. Evaluate Material Compatibility

When choosing welding wire, it is crucial to consider the compatibility between the welding wire and the base metal being welded. Misalignment in material compatibility can lead to poor weld quality, lack of fusion, or even weld failure. Here are some important factors to consider:

3.1 Matching Welding Wire and Base Metal

To ensure a strong and durable weld, it is important to match the welding wire material with the base metal material. Welding wire manufacturers provide guidelines and recommendations for suitable welding wire and base metal combinations. It is important to refer to these guidelines to ensure compatibility.

3.2 Dissimilar Metal Welding

In some cases, it may be necessary to weld different types of metals together. This is known as dissimilar metal welding. When performing dissimilar metal welding, it is important to choose welding wire that is specifically designed for this purpose. These types of welding wires have special alloy compositions that promote proper bonding between different metals.

3.3 Chemical Composition Considerations

The chemical composition of the base metal being welded should be taken into consideration when choosing welding wire. Certain elements in the base metal can affect the weld quality and properties. It is important to select welding wire with a composition that complements the base metal and provides the desired mechanical and corrosion resistance properties in the weld.

3.4 Galvanic Corrosion Potential

Galvanic corrosion can occur when two dissimilar metals are in contact in the presence of an electrolyte, such as moisture. When selecting welding wire, it is important to consider the galvanic corrosion potential between the welding wire and the base metal. Choosing welding wire with a similar galvanic potential to the base metal can help minimize the risk of galvanic corrosion.

4. Assess Wire Diameter and Size

The diameter and size of the welding wire can have a significant impact on the welding process and the quality of the weld. Here are some things to consider:

4.1 Determining Wire Thickness

The thickness of the base metal being welded will determine the appropriate wire thickness. It is important to select welding wire that matches the thickness of the base metal. Choosing the correct wire thickness ensures proper heat transfer and penetration, resulting in a strong and reliable weld.

4.2 Wire Feeding Capabilities

Different welding processes require specific wire feeding capabilities. It is crucial to choose welding wire that is compatible with the wire feeding mechanism of the welding equipment being used. Improper wire feeding can lead to inconsistent welds and poor weld quality.

4.3 Welding Current and Voltage

The diameter and size of the welding wire also play a role in determining the appropriate welding current and voltage settings. It is important to choose welding wire that can handle the current and voltage requirements of the specific welding process. Using the wrong wire diameter and size can lead to overheating, melt-through, or inadequate fusion of the weld.

5. Analyze Wire Composition

The composition of the welding wire is another important factor to consider when choosing the right welding wire. Different compositions offer varying mechanical properties and performance characteristics. Here are some key considerations:

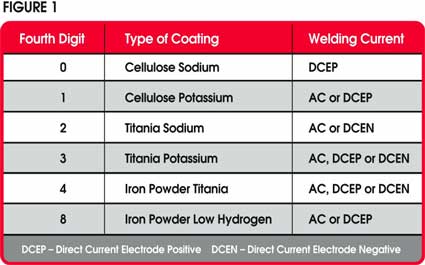

5.1 AWS Classifications

The American Welding Society (AWS) has established classifications for different welding wire compositions. These classifications provide information about the chemical composition and mechanical properties of the welding wire. It is important to choose welding wire that meets the appropriate AWS classification for the desired application.

5.2 Ferritic, Martensitic, and Austenitic Stainless Steel

When it comes to stainless steel welding wire, there are three main types: ferritic, martensitic, and austenitic stainless steel. Ferritic stainless steel offers good corrosion resistance and is suitable for applications where high strength is not required. Martensitic stainless steel provides high strength and hardness, but with lower corrosion resistance. Austenitic stainless steel offers excellent corrosion resistance and is commonly used in a wide range of applications.

5.3 Aluminum Alloys

Aluminum welding wire is available in various alloys, each with its own unique properties. The alloy composition determines the strength, weldability, and corrosion resistance of the weld. It is important to choose aluminum welding wire that is compatible with the specific aluminum alloy being welded.

5.4 Copper Alloys

Copper alloy welding wire is available in different compositions, such as bronze, brass, and copper-nickel alloys. Each composition offers specific properties and characteristics, such as high electrical conductivity or improved corrosion resistance. Proper selection of copper alloy welding wire ensures optimal performance and reliability in the weld.

5.5 Nickel Alloys

Nickel alloy welding wire is available in various compositions, such as Inconel and Monel. Each composition offers unique properties, such as high temperature resistance and corrosion resistance. The selection of the appropriate nickel alloy welding wire depends on the specific application and the desired performance of the weld.

5.6 Titanium Alloys

Titanium welding wire is available in different grades, each designed for specific applications. The grade of the titanium alloy determines its mechanical properties, such as strength, ductility, and corrosion resistance. Choosing the correct titanium welding wire ensures proper weld quality and performance.

6. Consider Shielding Gas Requirements

Shielding gas is an essential component of certain welding processes, such as MIG and TIG welding. The type of shielding gas used can have a significant impact on the weld quality and characteristics. Here are some factors to consider when choosing the right shielding gas:

6.1 Inert Gases (Argon, Helium)

Inert gases, such as argon and helium, are commonly used as shielding gases in welding. They provide an inert atmosphere that protects the weld from atmospheric contamination. Argon is the most commonly used shielding gas for MIG and TIG welding. Helium is often used in applications that require higher heat input and deeper penetration.

6.2 Active Gases (Carbon Dioxide, Oxygen)

Active gases, such as carbon dioxide and oxygen, can also be used as shielding gases in specific welding processes. Carbon dioxide is commonly used in MIG welding, as it provides good penetration and higher welding speeds. Oxygen is used in certain applications where improved arc stability and deeper penetration are required.

6.3 Mixtures

Shielding gas mixtures, such as argon-CO2 or argon-O2, can provide a combination of desired characteristics. These mixtures are often used to achieve specific weld properties, such as improved arc stability, reduced spatter, and increased penetration. It is important to choose the appropriate shielding gas mixture for the specific welding process and desired weld quality.

7. Assess Mechanical Properties

The mechanical properties of the weld are crucial for determining the strength, ductility, and overall performance of the welded joint. Here are some key mechanical properties to consider:

7.1 Tensile Strength

Tensile strength measures the maximum stress that a weld joint can withstand before breaking. It is an important factor in applications where structural integrity and load-bearing capacity are critical. When choosing welding wire, it is important to consider the desired tensile strength requirements of the weld and select wire that can meet those requirements.

7.2 Yield Strength

Yield strength refers to the stress at which permanent deformation or plastic deformation begins to occur in a weld joint. It is an important consideration in applications where cyclic loading or repeated stress is expected. Choosing welding wire with an appropriate yield strength ensures that the weld joint can withstand the anticipated loads and stresses.

7.3 Elongation

Elongation measures the ability of a weld joint to stretch or deform before breaking. It is an important mechanical property in applications where ductility and flexibility are important. High elongation values indicate that the weld joint can withstand deformation without failure. When selecting welding wire, it is important to consider the desired elongation properties of the weld.

7.4 Impact Toughness

Impact toughness measures the ability of a weld joint to withstand sudden impact or shock loading. It is an important property for applications where the weld joint may be subjected to unexpected loads or impacts. Choosing welding wire with good impact toughness ensures that the weld joint can withstand sudden forces without fracturing or breaking.

8. Evaluate Cost and Availability

Cost and availability are important factors to consider when choosing the right welding wire for your project. Here are some considerations:

8.1 Initial Cost

The initial cost of welding wire includes the purchase price of the wire itself. Different types of welding wire have varying costs, depending on factors such as material composition, diameter, and brand. It is important to consider the initial cost when budgeting for your welding project.

8.2 Operational Cost

In addition to the initial cost, the operational cost of welding wire should also be considered. This includes factors such as wire consumption and productivity. Some types of welding wire may have higher consumption rates or require more frequent replenishment, which can increase operational costs. It is important to assess the operational cost over the lifespan of your welding project.

8.3 Supplier Availability

When choosing welding wire, it is important to consider the availability of suppliers. Different types of welding wire may be more readily available from certain suppliers or manufacturers. It is essential to choose a reliable and reputable supplier to ensure consistent quality and availability of the welding wire.

9. Consider Environmental Factors

Environmental factors can have an impact on the welding process and the performance of the weld. Here are some important considerations:

9.1 Indoor or Outdoor Use

The location of the welding project, whether indoor or outdoor, can affect the choice of welding wire. Different types of welding wire may have different requirements for ventilation and atmospheric conditions. It is important to select welding wire that is suitable for the specific working environment.

9.2 Weather Conditions

Weather conditions, such as high humidity or extreme temperatures, can affect the welding process and the quality of the weld. Some types of welding wire may be more sensitive to environmental factors than others. It is important to choose welding wire that can withstand the weather conditions of the specific welding project.

9.3 Fume and Gas Emissions

Welding produces fumes and gases that can be hazardous to health and the environment. It is important to choose welding wire that minimizes fume and gas emissions. Different types of welding wire may have different levels of fume generation and emissions. It is important to assess the potential health and environmental impact of the welding wire.

10. Seek Expert Advice

Choosing the right welding wire can be a complex process, especially for specialized applications or unique requirements. In such cases, it is advisable to seek expert advice from welding professionals and manufacturers. Here are some ways to obtain expert advice:

10.1 Consulting Welding Professionals

Welding professionals, such as certified welders or welding engineers, have extensive knowledge and experience in welding processes and materials. They can provide valuable insights and recommendations based on their expertise. Consulting with welding professionals allows you to tap into their specialized knowledge and ensure proper selection of welding wire.

10.2 Manufacturer Recommendations

Welding wire manufacturers often provide detailed technical data sheets and product catalogs that contain valuable information about their welding wire products. These resources typically include recommendations and guidelines for specific applications and materials. Manufacturer recommendations can help guide your selection process and ensure the use of suitable welding wire.

10.3 Welding Wire Selection Guidelines

Various industry organizations, such as the American Welding Society (AWS), provide guidelines and standards for welding wire selection. These guidelines offer comprehensive information about different welding processes, welding wire classifications, and material compatibility. They serve as a valuable resource for making informed decisions when choosing welding wire.

In conclusion, choosing the right welding wire involves considering various factors, such as the type of welding wire, the welding process, material compatibility, wire diameter and size, wire composition, shielding gas requirements, mechanical properties, cost and availability, environmental factors, and seeking expert advice. By carefully evaluating these factors, you can ensure the selection of welding wire that meets your specific welding project requirements and achieves high-quality, reliable welds.