So you’ve discovered a cracked weld, and you’re wondering how to fix it? Well, fear not! This article will explore practical techniques and tips to help you address this common issue.

Whether you’re a DIY enthusiast or a professional welder, we’ve got you covered.

From identifying the cause of the crack to choosing the correct repair method, you’ll find all the information you need to fix a cracked weld successfully.

So, let’s get started and get your weld back in top shape!

Preparation

Before attempting to fix a cracked weld, it is essential to assess the extent of the damage and gather all the necessary tools and materials. This will ensure that the repair process goes smoothly and effectively.

Assessing the Damage

Begin by closely examining the cracked weld to determine the severity and location of the crack. This will help you determine the best approach for fixing it. Is the crack small and superficial, or does it run deep?

Are there any other signs of damage or fatigue in the surrounding area? Understanding the nature of the crack will guide you in choosing the appropriate repair method.

Gathering Necessary Tools and Materials

Once you have assessed the damage, gather all the tools and materials needed for the repair.

This may include welding tape, epoxy, a welder, appropriate safety gear (such as gloves and a welding helmet), a grinder, a drill, a backing plate, and any other equipment required for your specific repair method.

Temporary Fixes

Temporary fixes can help provide immediate stability to the cracked weld until a more permanent solution is implemented. Here are two common temporary fixes that you can try:

Using Welding Tape

Welding tape is a quick and convenient temporary fix for tiny cracks in the weld. Simply clean and dry the area around the crack, then apply the tape directly over the crack. The tape will provide some temporary reinforcement and prevent further crack spreading until a permanent repair can be done.

Using Epoxy

Epoxy is another temporary fix that can be used for small cracks. Clean the cracked area thoroughly, ensuring it is free from dirt or debris.

Mix the epoxy according to the manufacturer’s instructions and apply it directly onto the crack. Allow it to cure completely before using the welded item again. Although epoxy is not as strong as a welded repair, it can be effective in certain situations.

Mending with a Welder

For more permanent and reliable repairs, welding is the way to go. To properly mend a cracked weld, follow these steps:

Cleaning the Area

Before welding, cleaning the area around the crack is essential to ensure proper adhesion. Grind away any paint, rust, or debris from the surface using a grinder or wire brush. This will create a clean surface for the weld to bond with, resulting in a more substantial repair.

Choosing the Welding Method

The choice of welding method will depend on various factors, such as the type of material being welded and the size and location of the crack. Standard welding methods for repairing cracks include stick welding (SMAW), MIG welding (GMAW), and TIG welding (GTAW). Each method has advantages and considerations, so choosing the one that best suits your specific repair needs is essential.

Setting Up the Welder

Once you choose the appropriate welding method, ensure your welder is set up correctly. Follow the manufacturer’s instructions for adjusting settings such as amperage, wire speed, or electrode size. Take the time to familiarize yourself with your specific welder model’s controls and safety features.

Repairing Thin Cracks

Thin cracks in a weld can be repaired using the following steps:

Grinding the Crack

Begin using a grinder or rotary tool to carefully grind out the crack, creating a V-shaped groove along its length. This will allow for better penetration of the weld material and improve the overall strength of the repair.

Filling the Crack with Weld

Once the crack has been ground, it is time to fill it with weld material. Using the chosen welding method, carefully deposit the weld material into the groove, ensuring it fills the crack. Take your time and maintain a steady hand to achieve a clean and consistent weld bead.

Finishing Touches

After the weld has cooled, use a grinder or file to smooth rough edges or protrusions. This will help ensure a visually appealing and structurally sound repair. Finally, inspect the repaired weld for any signs of cracks or defects and make necessary adjustments or additional weld passes as needed.

Dealing with Thicker Cracks

Thicker cracks in a weld require a slightly different approach to ensure a successful repair. Follow these steps to mend thicker cracks effectively:

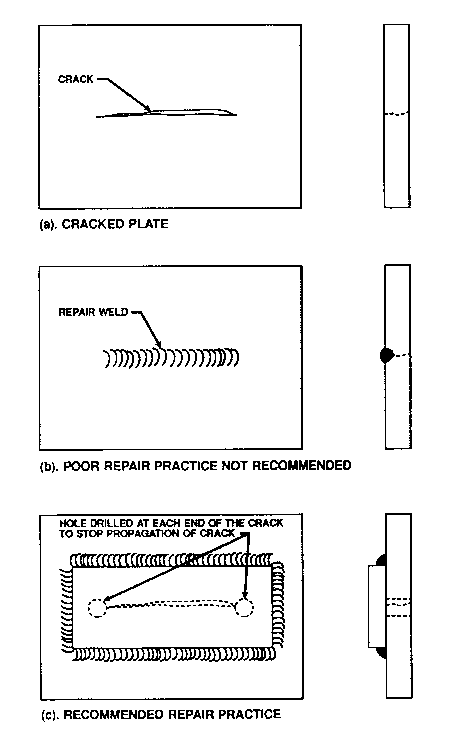

Drilling a Hole at Each End of the Crack

To prevent the crack from spreading further during the welding process, drilling a small hole at each end of the crack is recommended. This will serve as a stopping point for the weld and help contain the repair within the desired area.

Welding the Cracked Area

Using the appropriate welding method, carefully weld along the length of the crack, filling it with weld material. Be sure to maintain a consistent weld bead and avoid overheating the surrounding base metal. Take breaks as needed to prevent excessive heat buildup and potential warping.

Smoothing the Weld

Once the crack has been thoroughly welded, use a grinder or file to smooth the weld bead, blending it with the surrounding base metal. This will not only improve the appearance of the repair but also help ensure that the welded area is structurally sound and free from any sharp edges or protrusions.

Reinforcing and Strengthening the Weld

Sometimes, it is necessary to reinforce and strengthen the weld to prevent future cracks and enhance overall durability. Consider these additional measures:

Adding a Backing Plate

Adding a backing plate behind the cracked area can reinforce scenarios where added strength is required. The plate should be compatible and securely welded to the base metal, effectively distributing stress and preventing further cracking.

Stitch Welding

In some cases, stitch welding can reinforce the repaired weld. This technique involves creating intermittent welds along the length of the previously cracked area, effectively distributing stress and minimizing the likelihood of future cracks.

This method is beneficial for high-stress applications or where the base metal is prone to cracking.

Preventing Future Cracks

Repairing a cracked weld is just the first step towards keeping your welded items in optimal condition. To prevent future cracks and ensure long-lasting repairs, consider the following measures:

Identifying and Addressing Root Causes

It is crucial to identify the underlying causes of the crack to prevent it from happening again. Factors such as improper welding technique, inadequate material selection, or excessive stressors should be rectified. Consult welding professionals or industry experts to identify and resolve root causes effectively.

Regular Inspections and Maintenance

After repairing a cracked weld, it is essential to conduct regular inspections to ensure its ongoing integrity. Regular inspections can help identify any potential issues or signs of fatigue early on, allowing for timely repairs and preventing future cracking.

Additionally, implementing a proper maintenance routine, such as cleaning, lubricating, or reinforcing welded structures, can significantly extend their lifespan and reduce the likelihood of cracks.

Seeking Professional Help

Sometimes, it may be necessary to seek professional assistance to repair a cracked weld. Consider the following factors when determining the need for professional help:

Determining the Need for Professional Assistance

If the crack is extensive, particularly in critical and high-stress areas, or if you lack the necessary skills and equipment to perform a practical repair, it is best to seek professional help.

Welding professionals have the expertise and experience to assess the damage accurately and implement the most suitable repair methods for long-lasting results.

Finding a Welding Professional

When looking for a welding professional, consider their qualifications, certifications, and reputation within the industry. Seek recommendations from trusted sources or consult local welding associations for referrals.

Choosing a professional specializing in welding repair is essential, and can provide references and examples of their previous work.

Safety Precautions

When working with welding equipment and repairing cracked welds, it is crucial to prioritize safety. Always take the following safety precautions:

Wearing Proper Protective Gear

Protective gear, including welding gloves, a welding helmet with a proper filter, flame-resistant clothing, and steel-toed boots, should always be worn during welding and repair activities. This will protect you from potential burns, sparks, and other hazards associated with the welding process.

Clearing the Work Area

Ensure the work area is clear of flammable or combustible materials, as sparks and heat generated during welding can pose a fire hazard. Remove any potential tripping hazards, establish a safe perimeter, and secure your workpiece to prevent movement during the repair process.

Taking Fire Safety Measures

In an emergency, have appropriate fire extinguishing equipment nearby, such as a fire extinguisher or a bucket of sand. Familiarize yourself with proper fire safety procedures and use the extinguishing equipment effectively. Regularly inspect your welding equipment for any signs of damage or malfunction that could contribute to a fire hazard.

Final Thoughts

Repairing a cracked weld requires careful assessment, proper tools and materials, and a systematic approach. Whether you opt for temporary fixes or undertake permanent welding repairs, following the outlined steps will help you mend cracked welds effectively.

Knowing when to repair or replace a cracked weld is essential. Assess the severity of the crack and consult with professionals if needed, as they will have the expertise to determine the most appropriate course of action.

Lastly, continuous skill development is crucial in welding. Regularly practice and refine your welding techniques to ensure quality repairs and improve your welding abilities. Seek opportunities for training, attend workshops, and learn from experienced welders to continually enhance your skillset.

With the proper preparation, tools, and knowledge, you can confidently fix a cracked weld and restore strength and durability to your welded projects.