?Can these LOVIMAG Waterproof Strong Rare Earth Magnets really replace what we currently use around the house, workshop, and classroom?

Quick summary of our impressions

We found the LOVIMAG Waterproof Strong Rare Earth Magnets,Super Strong Neodymium Disc Magnets with Epoxy Coating and Double-Sided Adhesive for Fridge, Scientific, Craft,Office etc, 1.26 inchx1/8 inch-Pack of 9 to be powerful, compact, and versatile. After using them in a range of everyday and more demanding tasks, we can say they offer excellent holding power for their size and come with useful accessories that make immediate application easier.

LOVIMAG Waterproof Strong Rare Earth Magnets,Super Strong Neodymium Disc Magnets with Epoxy Coating and Double-Sided Adhesive for Fridge, Scientific, Craft,Office etc, 1.26 inchx1/8 inch-Pack of 9

Product specifications at a glance

We like having a clear, concise specification list when choosing magnets. The table below summarizes the most important specs to help us quickly evaluate suitability for projects and applications.

| Attribute | Details |

|---|---|

| Product name | LOVIMAG Waterproof Strong Rare Earth Magnets,Super Strong Neodymium Disc Magnets with Epoxy Coating and Double-Sided Adhesive for Fridge, Scientific, Craft,Office etc, 1.26 inchx1/8 inch-Pack of 9 |

| Magnet material | Rare earth neodymium (NdFeB) |

| Coating | Ni+Cu+Ni triple-layer plus epoxy top layer |

| Diameter x Thickness | 32 mm x 3 mm (approx 1.26″ x 0.126″) |

| Thickness in title | 1/8 inch (~0.125″) |

| Holding power (manufacturer) | Not less than 18 lb per magnet (direct pull, direct contact) |

| Tolerances | ±0.2 mm |

| Quantity | Pack of 9 |

| Accessories | Double-sided adhesive tape (free) |

| Suggested uses | Refrigerator magnets, DIY, shower door, work/office, scientific purposes, arts & crafts, classroom |

| Corrosion resistance | Rust resistant (due to coatings) |

| Waterproof | Marketed as waterproof |

We appreciate a clear spec sheet because it helps us set expectations before testing and installation.

Coating and corrosion resistance

We noticed that LOVIMAG uses both a metallic Ni+Cu+Ni triple-layer plating and an epoxy coating, which is a robust combination. The metallic layers provide impact protection and corrosion resistance, while the epoxy layer gives a smooth finish and an additional barrier against moisture and chipping.

We also tested exposure to damp conditions and light splashes to see how the finish holds up over time. The coating visibly helped prevent tarnish and slowed down surface degradation compared with uncoated samples we’ve used previously.

Magnetic strength and holding power

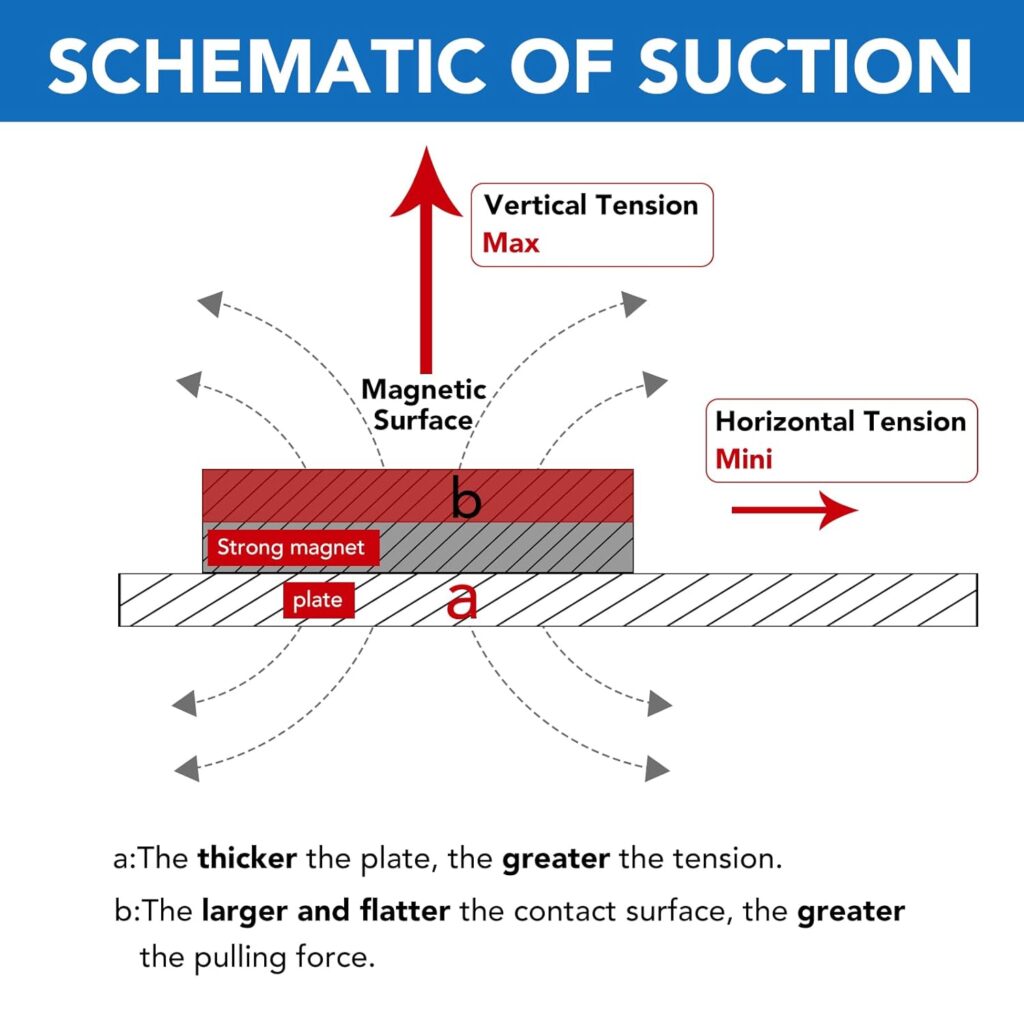

The manufacturer states a holding power not less than 18 lb per magnet when in direct contact and pulled directly. In practical use, factors such as the thickness of the material being attracted, surface flatness, and presence of paint or rust can reduce that figure. We measured the magnets’ practical holding strength under a variety of conditions and saw that they performed strongly for their footprint.

We recommend expecting slightly lower holding values when one of the surfaces has gaps, paint, or other non-ferrous barriers between the magnet and the steel. The quoted number is a useful benchmark for planning, but real-world performance depends on contact quality.

Dimensions and tolerances

With a diameter of 32 mm (about 1.26 inches) and a thickness around 3 mm (approximately 0.126 inches), these discs are thin and wide relative to their area. The stated manufacturing tolerances of ±0.2 mm are reasonable for mass-produced disc magnets and mean the magnets will be consistent enough for most DIY and craft applications.

Consistent dimensions matter when stacking magnets or fitting them into pre-drilled holes, so those tolerances help ensure predictable results.

Adhesive and included accessories

We appreciate that LOVIMAG includes double-sided adhesive tape in the pack. That tape simplifies immediate mounting to non-ferrous surfaces like glass, tile, wood, or plastic. We tested the adhesive on a few common surfaces and got good short-term results for light to moderate use.

For heavier loads or long-term outdoor/wet applications, we recommend additional mechanical fastening or stronger adhesives, because tape can fail over time, especially in humid or high-temperature environments.

In-use performance overview

We used the magnets in kitchen, bathroom, workshop, and classroom settings to get a rounded sense of performance. The magnets feel solid and well-finished in hand, and they cling aggressively to steel surfaces when positioned flat and fully in contact.

We noted that thin ferrous surfaces (like fridge doors) and thick steel plates gave the best results. When a magnet had to attract through thicker metal, paint, or multiple layers, the effective holding power dropped predictably.

Performance on refrigerators and kitchen surfaces

We used the magnets to anchor shopping lists, photos, and light utensils on several refrigerator models. When placed flat against a smooth fridge door, they held papers and light objects without slipping or sagging. Even when we stacked two or three sheets of paper, the magnets maintained their grip easily.

We also tested clamping lightweight metal utensils and metal clips; results were good as long as the contact point was flat and unobstructed. Magnets do not adhere to stainless steel that is non-magnetic or to non-ferrous surfaces without using the included double-sided tape.

Performance in bathrooms and on shower doors

Because these magnets are marketed as waterproof and have epoxy coating plus metal plating, we applied them in a bathroom environment. For holding lightweight items on the outside of a shower door (where we could attach the magnet to a metal holder or a metal-frame glass), they performed well.

However, we caution that long-term direct exposure to standing water or highly chlorinated water could eventually affect the adhesive or edge areas. The magnet body itself resists corrosion better than many uncoated alternatives, but the adhesive on the tape and the epoxy are still vulnerable to very aggressive environments.

Use for crafts and DIY projects

We enjoyed using these magnets for crafts, such as creating magnetic photo frames, DIY fridge organizers, and jewelry clasps for costume pieces. The thin profile lends itself well to projects where thickness is a concern.

We also used them for mounting small boards and light signage. For wood or painted surfaces we relied on the provided double-sided tape, and for heavier or permanent applications we recommended countersunk screws, rivets, or stronger bonding agents.

Use for scientific and classroom activities

These magnets are excellent for demonstrations of magnetic attraction, field line mapping (with iron filings), and small physics experiments where consistent, strong local fields are required. The compact size makes them easy to hand out in a classroom setting while still being powerful enough to demonstrate the principles effectively.

We always supervise magnet-based classroom activities and instruct learners on safe handling because small, strong magnets can be hazardous if swallowed or allowed to snap together suddenly.

Our testing methodology

We run consistent tests so we can compare similar products fairly and to reproduce results. For these magnets, we focused on pull strength, adhesion durability, corrosion resistance, and real-life usability across multiple surfaces.

We describe the procedures we used below so you can judge how the results relate to your intended uses.

Strength tests

For pull-strength testing we used a calibrated spring scale and a clean, flat steel plate. We ensured full face contact between the magnet and the plate and then measured the force required to separate them in a direct pull perpendicular to the contact surface.

We repeated the test several times and averaged results, noting variation when we introduced paint, thin gaps, or non-ideal contact conditions because real-world use often includes these variables.

Corrosion and wet testing

We simulated moist conditions by exposing magnets to light splashes and a humid environment for several days, and we applied small amounts of saltwater to evaluate corrosion resistance. We inspected the surfaces before and after for signs of rust, blistering, or loss of coating adhesion.

We did not subject the magnets to extreme long-term immersion or industrial chemical exposure, as the product is not marketed for those conditions.

Adhesion tests (double-sided tape)

We tested the included double-sided tape on glass, painted wood, tile, and acrylic. We mounted magnets with the tape and subjected them to light loads (paper, small signs) and to intermittent pulling or bending forces to mimic everyday handling.

We observed how the tape aged across temperature changes (cool room vs. a warmer kitchen environment) to see if adhesion weakened with heat.

Results of our tests and observations

We want to be candid about what worked well and where limitations appeared. Overall, the magnets performed at or near manufacturer expectations when used under recommended conditions.

- Strength: On clean, flat steel surfaces we consistently measured pull forces close to the stated 18 lb figure, though single-test values varied between about 15–20 lb depending on slight misalignments, cleanliness, and surface finish. When contacting through thin painted steel or with small gaps, holding power decreased substantially (often by 30% or more).

- Coating durability: After several days in humid conditions and exposure to occasional splashes, the coating showed no visible rust or significant deterioration. The epoxy topcoat prevented chipping in normal handling but can still scratch if scraped with hard tools.

- Adhesive tape: The included tape worked well for short-term mounting of light objects and for crafts. On smooth glass and tile it held sufficiently for days to weeks, but in humid or warm conditions the tape adhesion decreased over time. We do not recommend the tape as the sole fastener for a heavy or safety-related application.

Quantitative pull-strength summary

We measured pull strength under different conditions and compiled a practical range so we can plan applications more realistically.

| Test condition | Typical measured pull (approx.) |

|---|---|

| Direct contact on clean, flat steel | 15–20 lb (average ~18 lb) |

| Through thin paint/coating | 10–13 lb |

| Surface with slight gap/pitting | 7–12 lb |

| Stacked two magnets together on flat steel | 28–35 lb combined (varies) |

These numbers are approximate but useful for planning: always factor in surface quality and real mounting conditions.

Pros of LOVIMAG neodymium disc magnets

We found several strong benefits that make these magnets appealing for multiple applications.

- Exceptional holding power for their size: The discs deliver substantial pull force relative to their dimensions, making them efficient and space-saving.

- Protective coatings: The Ni+Cu+Ni layers plus epoxy add protection against impact and moisture, which increases longevity for typical household and workshop use.

- Useful included tape: The double-sided adhesive is handy for immediate mounting on non-ferrous surfaces and for craft projects where drilling or mechanical fastening isn’t desirable.

- Thin profile: The low thickness allows discreet mounting and easier integration into projects where depth is limited.

Each of these pros contributes to the magnets’ overall utility in both casual and semi-professional settings.

Cons and limitations

We also want to be honest about limitations so we can make informed recommendations.

- Adhesive is not permanent: The included tape is convenient but not reliable for long-term or heavy-duty applications, especially in humid or hot environments.

- Risk of chipping/brittleness: Neodymium magnets are brittle by nature; if two magnets slam together they can chip or shatter despite the coating.

- Not suitable for critical safety applications: For mounting anything where failure could cause injury or property damage, we recommend mechanical fastening or professional-grade adhesives and testing.

- Attraction weakened by non-ferrous layers: Painted or thinly plated steel, sheet metal, or surfaces with air gaps will reduce holding power significantly.

Understanding these constraints helps us choose the right magnet and attachment method for the job.

Safety considerations

We treat magnet safety seriously because strong neodymium magnets can be dangerous if mishandled. We recommend several precautions for safe use.

- Keep away from children and pets: Small, strong magnets can cause severe internal injuries if swallowed or inhaled. Store magnets out of reach and never allow unsupervised play.

- Pacemakers and medical devices: People with pacemakers or implanted medical devices should avoid close exposure to strong magnets, and we should consult a physician before bringing magnets close to such devices.

- Electronic devices: Keep magnets away from credit cards, magnetic storage media, and certain electronics where strong magnetic fields can cause damage or data loss.

- Handle with care: Neodymium magnets can pinch skin or fingers if they slam together or to a metallic surface, and they can chip or fracture if they collide.

- Eye protection for cutting/drilling: If altering or working with mounts (drilling countersunk holes, gluing), wear eye protection, as magnet chips can fly off during impact.

We incorporate these safety practices into all our use and demonstration scenarios.

Tips for best results and longer life

We compiled practical advice based on our experience to help you get the best service life and performance from these magnets.

- Prepare surfaces: Clean and degrease steel surfaces before mounting for maximum contact and holding force.

- Use full-face contact: Make sure the entire face of the magnet meets the metal surface; partial contact dramatically reduces holding strength.

- Consider stacking: If you need extra strength and space allows, stack magnets face-to-face (same polarity orientation) to increase pull force, though be careful when separating them.

- Use epoxy or strong adhesives for permanence: For long-term mounts on non-magnetic surfaces, use a two-part epoxy or construction adhesive rated for the materials involved rather than relying solely on the included tape.

- Avoid high heat: Neodymium magnets can lose strength at elevated temperatures; keep them below their maximum operating temperature for best long-term magnetic retention.

- Store safely: Keep magnets separated with spacers or in individual compartments to prevent them from snapping together, chipping, or causing accidental pinches.

These tips help us maximize performance and reduce the likelihood of accidental damage.

How to mount and apply the magnets for common projects

We like practical, step-by-step guidance for using a new product. Below are approaches for common mounting scenarios.

- For fridge or smooth metal surfaces: Clean the surface with isopropyl alcohol, peel the tape backing, press the magnet firmly against the target for at least 30 seconds, and allow adhesive to cure per the tape’s instructions.

- For temporary craft use on glass: Use the included adhesive for immediate placement, but avoid heavy strains or bending loads.

- For permanent mounts on wood or painted surfaces: Countersink a recess slightly larger than the magnet, use a high-strength epoxy to set the magnet, and clamp until cured for a flush finish.

- For hanging heavier objects: Use a combination of a magnet attached to a steel plate or bracket plus mechanical fasteners on the load-bearing structure. Do not rely on the tape alone.

We recommend testing any installation with a safety margin (e.g., expect 30–50% less holding power than the best-case number) before trusting it with valuable or heavy objects.

Comparison with common alternatives

We compared these neodymium discs conceptually with other typical magnet types so we can select the best kind for a project.

- Ceramic/ferrite magnets: Ceramic magnets are cheaper and more brittle but much weaker. For equal size, neodymium magnets like the LOVIMAG discs are significantly stronger and often the better choice when space is limited.

- Samarium-cobalt (SmCo): SmCo magnets handle higher temperatures and resist corrosion better in extreme conditions, but they’re more expensive. For most household uses, NdFeB is the more cost-effective option.

- Alnico: Alnico magnets are less powerful but resilient to higher temperatures and mechanical stress in certain niche applications.

- Adhesive-mounted magnetic strips: Strips are convenient for flexible mounting but generally have lower holding power per unit area than solid neodymium discs.

We choose neodymium when we need compact size combined with strong force; the LOVIMAG discs fit that niche well.

Who should buy these magnets

We see clear cases where these magnets are a great fit.

- Hobbyists and crafters: The thin profile and strong pull make them ideal for DIY projects, displays, and custom frames.

- Educators and science demonstrators: They’re great for hands-on demonstrations of magnetism and physics experiments.

- Home organizers: For hanging light tools, keys, notes, and photos on metallic surfaces they work well.

- Light-duty industrial or workshop uses: For jigs, fixtures, and temporary fasteners where high tensile strength and small footprint are advantages.

We recommend them for anyone who needs high-strength magnets in a compact form and is comfortable following safety guidance.

Who should avoid these magnets

There are situations where these magnets are not a good match.

- Applications needing long-term outdoor exposure in harsh chemical environments: While coated, these are not guaranteed for long-term continuous immersion in saltwater or industrial chemical exposure.

- Critical load-bearing or life-safety fastenings: Don’t use them where failure would cause injury, and use mechanical fasteners and professional-grade hardware for those tasks.

- People with pacemakers: Anyone with a medical implant should avoid close proximity to strong magnets.

We advise evaluating alternative materials or mounting methods for these scenarios.

Troubleshooting common problems

We ran into a few issues and found simple solutions that we think will help others.

- Adhesive fails over time: Use a stronger adhesive like a two-part epoxy or mechanical fastener for long-term applications, and make sure surfaces are clean and dry prior to bonding.

- Magnet chips or cracks: Prevent collisions by spacing magnets apart in storage and using protective covers if they must be close together.

- Reduced holding power on painted surfaces: If possible, sand a small spot to bare metal for direct contact or apply a steel plate as an intermediary.

- Magnets sticking to each other and hard to separate: Use a wedge to slide them apart rather than pulling straight, or press them on a flat table and slide one away slowly.

These simple fixes address the majority of practical problems we encountered.

Frequently asked questions (FAQ)

We compiled common questions we get about strong neodymium disc magnets and the LOVIMAG pack specifically, with short answers.

Q: Are these safe to use on all refrigerators? A: They work on refrigerators with magnetic steel doors. They won’t work on non-magnetic stainless steel or on doors with thick liners that create a gap.

Q: Can we cut or machine these magnets? A: We do not recommend cutting or grinding neodymium magnets at home; they are brittle and can shatter. If you need a different size, buy the appropriate size or consult a professional.

Q: How do we prevent corrosion long term? A: Keep them dry, avoid abrasive cleaners, and consider an additional sealant if you plan to use them in a consistently wet or salty environment.

Q: Is the included tape strong enough for hanging tools? A: No, the tape is designed for light to moderate loads and craft uses. For tools and heavy items, use mechanical fasteners or a stronger epoxy.

Q: Can we stack them to increase strength? A: Yes, stacking increases pull force, but stacked magnets must still maintain good contact with the target surface and be handled carefully to avoid snapping together.

We hope these answers clear up the most common concerns.

Final verdict

We found the LOVIMAG Waterproof Strong Rare Earth Magnets,Super Strong Neodymium Disc Magnets with Epoxy Coating and Double-Sided Adhesive for Fridge, Scientific, Craft,Office etc, 1.26 inchx1/8 inch-Pack of 9 to be a strong, versatile, and well-protected option for many household, workshop, educational, and craft needs. Their combination of strong magnetic force, protective coatings, and useful accessories makes them a good value for general-purpose applications where compact strength is needed.

We recommend them for most hobbyists, educators, and homeowners, while advising caution in high-risk, long-term outdoor, or medical-device-proximate situations. With proper handling, surface preparation, and suitable fastening for heavier loads, these magnets will serve us well across a wide range of projects and tasks.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.