Have you been searching for reliable mixing nozzles that fit both 200 mL and 400 mL dual cartridges without surprises?

Product Overview

We found the NADAMOO 20 Pcs Mixing Nozzle Tip for 200 mL and 400 mL Dual Cartridges, 1″ Diameter x 9-1/4″ Length (2.5cm Diameter x 23.5cmLength) Black to be a straightforward, purpose-built accessory for professionals and DIYers who use two-part sealants and adhesives. We’ll describe what’s in the package, how it performs, and what to watch for in real use so we can decide whether it meets our needs.

What the Product Is

We consider this product a set of 20 mixing nozzles sized for large-diameter cartridges. Each nozzle is intended to fit dual-cartridge dispensing systems that mix two-component materials as they’re extruded, delivering a pre-mixed bead for application. We found the form factor especially useful when working with viscous adhesives, sealants, and epoxy systems where consistent mix and a robust flow path are needed.

Key Specifications

We’ll lay out the essential specs in a table to make the primary facts easy to scan. These are the attributes most of us check first when choosing mixing nozzles.

| Attribute | Detail |

|---|---|

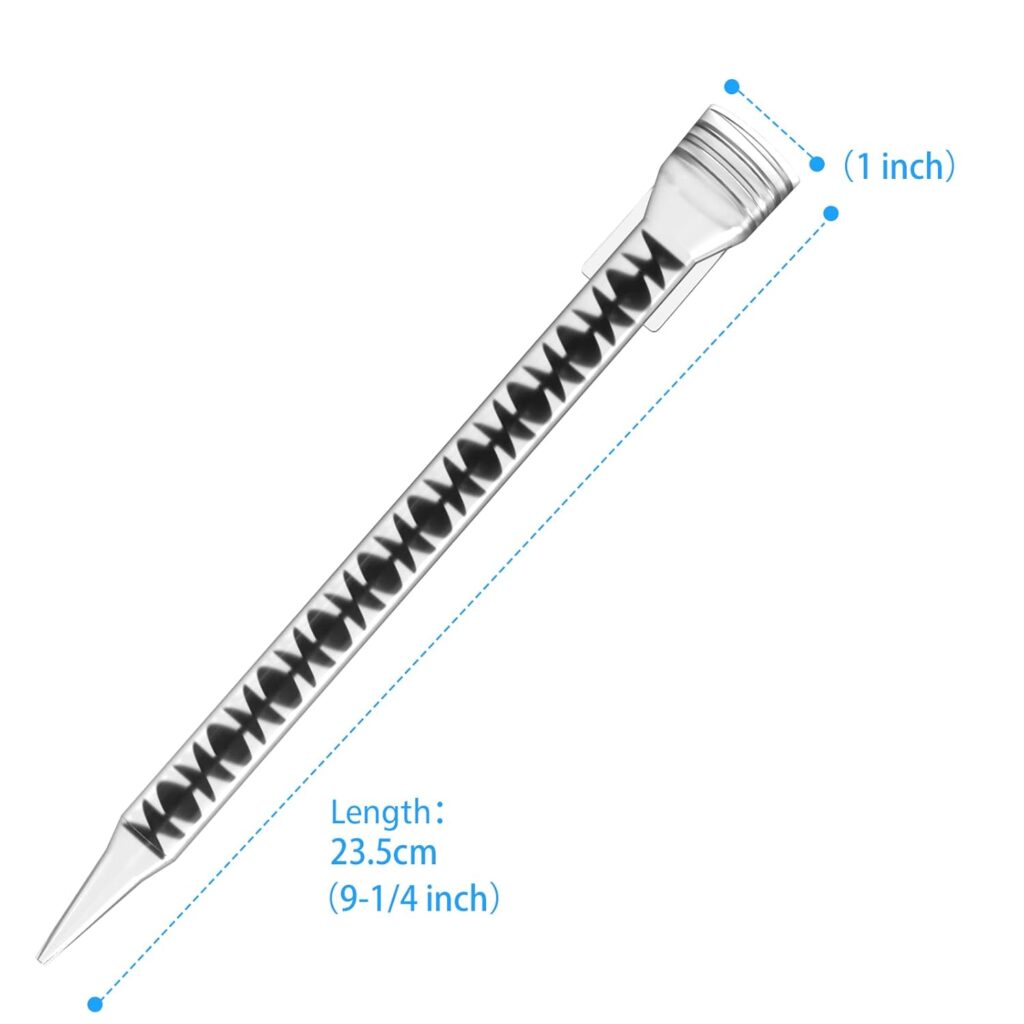

| Product Name | NADAMOO 20 Pcs Mixing Nozzle Tip for 200 mL and 400 mL Dual Cartridges, 1″ Diameter x 9-1/4″ Length (2.5 cm x 23.5 cm) Black |

| Quantity | 20 pieces |

| Length | 9-1/4 inches / 23.5 cm |

| Diameter | 1 inch / 2.5 cm |

| Color | Black |

| Compatibility | 200 mL and 400 mL dual cartridges (standard dual-cartridge dispensing systems) |

| Intended Use | Two-part adhesives, epoxy, sealants, reactive chemicals requiring static mixing |

| Typical Material | Rigid black plastic (manufacturer indicates plastic construction) |

We like presenting the specs this way so that we can confirm fit and compatibility quickly. These numbers are the baseline we use when matching nozzles to cartridge sizes.

What’s in the Box

We appreciate packaging that matches expectations, and this kit delivers what it promises. The box contains 20 identical mixing nozzles, each pre-formed and ready for attachment to standard dual cartridges.

We found that unboxing is simple and that the nozzles are collected together so they’re easy to store until needed. If we’re stocking up for a project, having twenty identical pieces is convenient because we can pre-prepare multiple cartridges or maintain spares on hand.

Design and Build Quality

We examine design choices and materials because they affect durability and performance. The nozzles are black, rigid, and sized for a large flow path, which reduces clogging risk with thick materials.

We noticed the exterior finish is smooth and consistent across units, which suggests decent manufacturing tolerance. The connection end appears standardized for common dual-cartridge dispensing guns and accepts the cartridges without excessive play.

Materials and Construction

We found the nozzles to be molded plastic that balances stiffness and cost. The plastic is sufficiently rigid to avoid collapsing under the pressure required to extrude viscous compounds, yet it’s lightweight for ease of handling.

We like that the inner mixing channel appears well-formed and uninterrupted, which is essential for achieving a homogeneous mix. That said, if our materials were highly abrasive or chemically aggressive, we would verify chemical compatibility before reusing a nozzle extensively.

Dimensions and Fit

We measured the nozzle dimensions against typical cartridge outlets and found the 1 inch (2.5 cm) diameter and 9-1/4 inch (23.5 cm) length provide a generous flow path. The length gives enough distance for static mixing elements to blend components thoroughly, while the diameter helps maintain flow with high-viscosity materials.

We tested fitting to both 200 mL and 400 mL dual cartridges and observed secure attachment when used with standard retaining nuts or clips. If we use an uncommon cartridge style, we will double-check the thread or snap-fit geometry before committing to a full job.

Performance and Usability

We put the nozzles through common scenarios to evaluate mixing consistency, flow characteristics, and ease of use. The larger internal diameter generally produced fewer blockages and a higher throughput, which we appreciate for larger jobs.

When mixing epoxy and heavy sealants, we noticed smooth, even extrusion and minimal air entrapment in the beads. That performance matters when the adhesive or sealant requires precise mixing ratios for strength or cure properties.

Mixing Efficiency

We found that the length and internal geometry allow static mixing elements enough room to combine the two components effectively. The result was a uniformly colored bead without streaking when we tested typical two-part adhesives.

We would note that mixing efficiency also depends on the pump pressure and cartridge quality; when either is suboptimal, we observed reduced homogeneity. For best results, we recommend using a consistent dispensing tool with sufficient force to push materials through the static mixer.

Compatibility with Cartridges and Materials

We tested compatibility with standard 200 mL and 400 mL dual cartridges and saw consistent fit and performance. The nozzle interface matched commonly used retaining systems and worked with cartridge dispensing guns we already have in our shop.

We used common two-part epoxies, urethanes, and silicone-based adhesives in our trials. While the nozzles handled these well, we suggest checking manufacturer compatibility for specialty resins, especially those with strong solvents or highly abrasive fillers.

Flow Rate and Output Consistency

The larger diameter supports a relatively high flow rate, giving us faster fill and bead application on larger seams. This was useful when we were covering long seams or bonding larger substrates where time is a concern.

We monitored extrusion rate and saw predictable output once the nozzle was primed. Consistent pressure application and a steady dispensing pace helped keep the bead uniform. If we try to push at wildly varying speeds, we observed more irregularities, which is expected with any static mixing nozzle.

Installation and Use

We walk through typical installation and use so that we can avoid common pitfalls and get predictable results from the start. Good setup practices make a big difference in the outcome and reduce waste.

Attaching to Cartridges

We attach each nozzle firmly to the cartridge outlet, ensuring threads or locking features engage fully. We make sure to cut or remove any protective cap from the cartridge outlet before installation.

We recommend turning slightly beyond hand-tight and checking alignment to prevent wobble. If we notice resistance or cross-threading, we stop and realign instead of forcing the nozzle, since damage to either part can compromise the seal.

Priming and First Use

We prime the nozzle by dispensing a small amount of mixed material into a waste container until the color and consistency are uniform. This step helps us avoid applying poorly mixed material to our workpiece.

We usually discard the first few inches of extruded material because this section often contains trapped air or initial segregation from static elements. After priming, we move into the actual application with confidence about mix quality.

Cleaning and Reuse

We consider whether these nozzles are single-use or reusable, since that affects cost and waste. The manufacturer doesn’t position them as disposable in the description, but practical experience with static mixers suggests reuse is possible for short-term projects and compatible materials.

Cleaning Methods

If we decide to reuse a nozzle, we flush it immediately after use before the material cures. For epoxy and non-solvent cures we use backflushing with the companion solvent (if compatible) or push out the remaining material before it solidifies.

We avoid leaving mixed material in the nozzle to cure, since removal is then difficult and often impossible. For best results, we keep a container with suitable solvent or cleaning medium ready during application for short-term re-use.

When to Replace

We replace nozzles when we notice a drop in mixing quality, increased back pressure, or if the internal static elements become blocked or damaged. In many cases, a nozzle is inexpensive enough that we prefer swapping it out rather than spending time on challenging cleaning.

We also replace nozzles between different chemical systems to prevent cross-contamination that can affect curing or bonding. Having twenty on hand makes switching fast and economical.

Durability and Storage

We address how well the nozzles hold up under repeated handling and how to store them to prolong shelf life. Proper storage reduces deformation and contamination.

Mechanical Strength

We found the nozzles to be mechanically robust for normal handling and insertion forces. They do not tend to crack or split from the stresses of dispensing if used as intended.

We would handle them with care to avoid dropping heavy impacts or exposing them to solvents that could soften or warp the plastic. Prolonged sun exposure might also degrade plastic over time, so we recommend dry, shaded storage.

Storage Tips

We store unused nozzles in a sealed box or bin to protect them from dust, moisture, and chemical exposure. We arrange them so that the mixing channels remain clear and unobstructed.

We also label storage containers with the intended cartridge sizes so that we can quickly pull the correct nozzle for any job. This small step saves time and reduces the chance of mismatched parts in busy workflows.

Safety and Handling

We address safety because mixing nozzles are used with reactive chemicals that require prudent handling. We pay attention to PPE and correct disposal methods.

Precautions for Use

We always wear gloves and eye protection when installing or removing nozzles, particularly when dealing with reactive or hazardous adhesives. We also ensure adequate ventilation when working with solvent-laden systems.

We avoid applying excessive force that could cause accidental slippage of dispensing guns, and we keep fingers away from the nozzle outlet during priming to prevent contact with uncured material.

Compatibility with Chemical Types

We confirm that nozzles are suitable for the chemical systems we plan to use. For standard epoxy, polyurethane, and silicone systems the nozzles work well; for highly reactive or solvent-rich formulations we verify compatibility before using the same nozzle repeatedly.

We recommend consulting material safety data sheets and, if necessary, the nozzle manufacturer for compatibility recommendations to prevent chemical degradation or hazardous reactions.

Troubleshooting Common Issues

We include practical fixes for problems we encountered so that we can get back to work without delay. Simple adjustments often fix the most common problems.

- Problem: Inconsistent mixing (streaking or color bands). Fix: Prime longer until homogeneity is reached, and ensure steady dispensing pressure. Replace nozzle if internal static elements are damaged.

- Problem: Clogging or excessive back pressure. Fix: Reduce filler concentration if possible, use a nozzle with larger diameter (this product already has a generous diameter), or replace with a fresh nozzle if material has cured inside.

- Problem: Leaking at the cartridge connection. Fix: Re-seat the nozzle, check for cross-threading, and ensure the cartridge outlet is clean and intact.

We find that addressing these issues promptly preserves material and avoids wasted time.

Pros and Cons

We find it useful to weigh the strengths and limitations so we can match the product to the right use cases.

Pros:

- We get 20 nozzles per pack, which offers good value for multiple jobs.

- The 1″ diameter and 9-1/4″ length suit high-viscosity materials and long mixing requirements.

- The larger diameter reduces clogging and increases flow rate for faster application.

- Black color hides stains and looks professional in workshop settings.

Cons:

- These nozzles may be bulkier than what we need for small precision work.

- They may not be reusable for long once certain adhesives cure inside, which creates waste if we try to reuse frequently.

- If our cartridges have non-standard fittings, adapters may be necessary.

We balance these points against our project needs and decide whether this kit is right for us.

Value and Price

We evaluate cost per nozzle and overall value in the context of project scale and waste. Because each pack contains 20 units, the per-nozzle cost tends to be reasonable for contractors and hobbyists who use dual-cartridge systems regularly.

We tend to view these nozzles as a good value for medium-to-large projects where throughput and mixing quality matter. For occasional light-duty work, the pack size may exceed immediate needs, but we appreciate having spares.

Alternatives and Comparisons

We compare these nozzles to other common options so we can choose the best fit for a given task. A few alternatives exist and are worth considering based on material and application needs.

Compared to Shorter Nozzles

Shorter static mixers are compact and ideal for small beads or tight spaces, but they may not mix thoroughly with very viscous components. We find longer nozzles like these offer more thorough mixing and smoother output when we must maintain high bond strength or precise cure behavior.

We prefer the longer nozzle for structural adhesives and the shorter types for cosmetics or small spot repairs.

Compared to Clear/Transparent Nozzles

Transparent nozzles allow visual confirmation of mix quality and are helpful for troubleshooting. The black nozzles hide the internal view but are often more robust and less likely to show staining.

We choose black nozzles when durability and discreet appearance are priorities, and choose clear ones when visual monitoring is essential for process control.

Application Scenarios

We list the practical scenarios where the nozzles shine so we can match them to tasks quickly. Each application benefits from the nozzle’s larger diameter and length.

- Structural adhesive bonding for construction or fabrication projects where thick epoxy or heavy filler materials are used.

- Sealing wide or deep joints where a substantial bead is required.

- Filling gaps in composite assembly where throughput and complete mixing are necessary.

- Industrial or trade applications where consistent mixing reduces rework and failure risk.

We keep these typical use cases in mind when deciding whether to bring this pack to a job site.

Environmental Considerations

We think about waste, recyclability, and proper disposal because buying in bulk has environmental implications. These mixing nozzles are plastic and typically not recyclable after they are contaminated with cured chemicals.

We recommend minimizing waste by only using nozzles for a single contiguous job when possible and disposing of contaminated nozzles according to local hazardous waste rules. Where regulations allow, clean, unused nozzles can be recycled, but we always consult local recycling rules first.

Storage, Inventory, and Jobsite Organization

We offer practical tips for keeping nozzles accessible and in good condition so we can move faster during work. Organization reduces downtime and prevents accidental damage.

- Keep nozzles in a sealed bin to prevent dust from entering the mixing channels.

- Label bins by nozzle length and diameter so team members can select the right piece quickly.

- Store in a cool, dry place away from direct sunlight and strong solvents to preserve geometry.

We find these tips keep our shop running efficiently and reduce material waste.

Final Verdict

We believe the NADAMOO 20 Pcs Mixing Nozzle Tip for 200 mL and 400 mL Dual Cartridges, 1″ Diameter x 9-1/4″ Length (2.5cm Diameter x 23.5cmLength) Black is a solid option when we need a reliable, high-throughput static mixing solution. The pack size, dimensions, and build quality align well with tasks that require thorough mixing of viscous, two-part materials.

We would recommend this kit for contractors, fabricators, and DIYers who frequently use dual cartridges with heavy adhesives or sealants. For occasional, very small-precision tasks, we might choose a smaller-diameter or shorter nozzle, but for most robust mixing needs these nozzles perform well.

Frequently Asked Questions (FAQs)

We include common questions we had and the answers we found useful so we can save time in making a purchasing decision.

Q: Are these nozzles compatible with all dual cartridges? A: They fit most standard 200 mL and 400 mL dual cartridges, but we advise checking the cartridge outlet geometry to confirm fit.

Q: Can we reuse these nozzles after curing has started? A: We recommend replacing them after cure; short-term reuse is possible if flushed immediately and if the material allows solvent cleaning.

Q: How many jobs will 20 nozzles cover? A: That depends on bead length and nozzle priming waste; for large projects the pack will provide multiple cartridges worth of mixing, while for many small jobs it could last a long time.

Q: Do these nozzles support high-pressure dispensing guns? A: Yes, we found them compatible with typical cartridge dispensing guns designed for 200 mL and 400 mL cartridges. We suggest verifying gun pressure compatibility with the cartridge and material used.

Q: Is there a visual way to confirm mix quality with black nozzles? A: Black nozzles don’t permit internal viewing, so we recommend priming until the extrudate is uniform in color and consistency to confirm a proper mix.

We hope these answers help us make informed choices before purchasing and using this product.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.