?Have we been looking for a reliable, organized way to repair automotive plastic parts without spending a fortune on replacement panels?

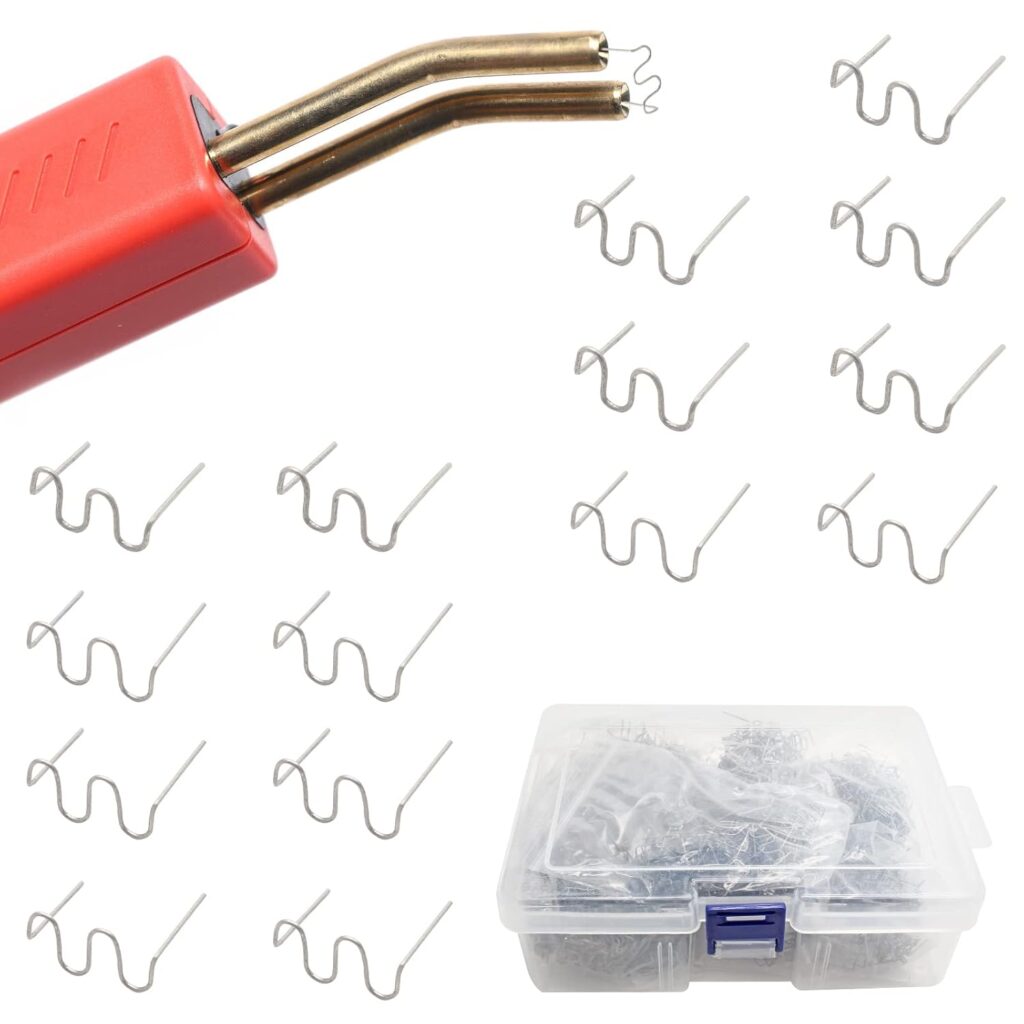

What is the Rierdge Hot Staples 0.6mm 0.8mm Wave Shaped Automotive Plastic Repair Machine Welding Hot Staples for All Cars with Storage Box, 1200 PCS?

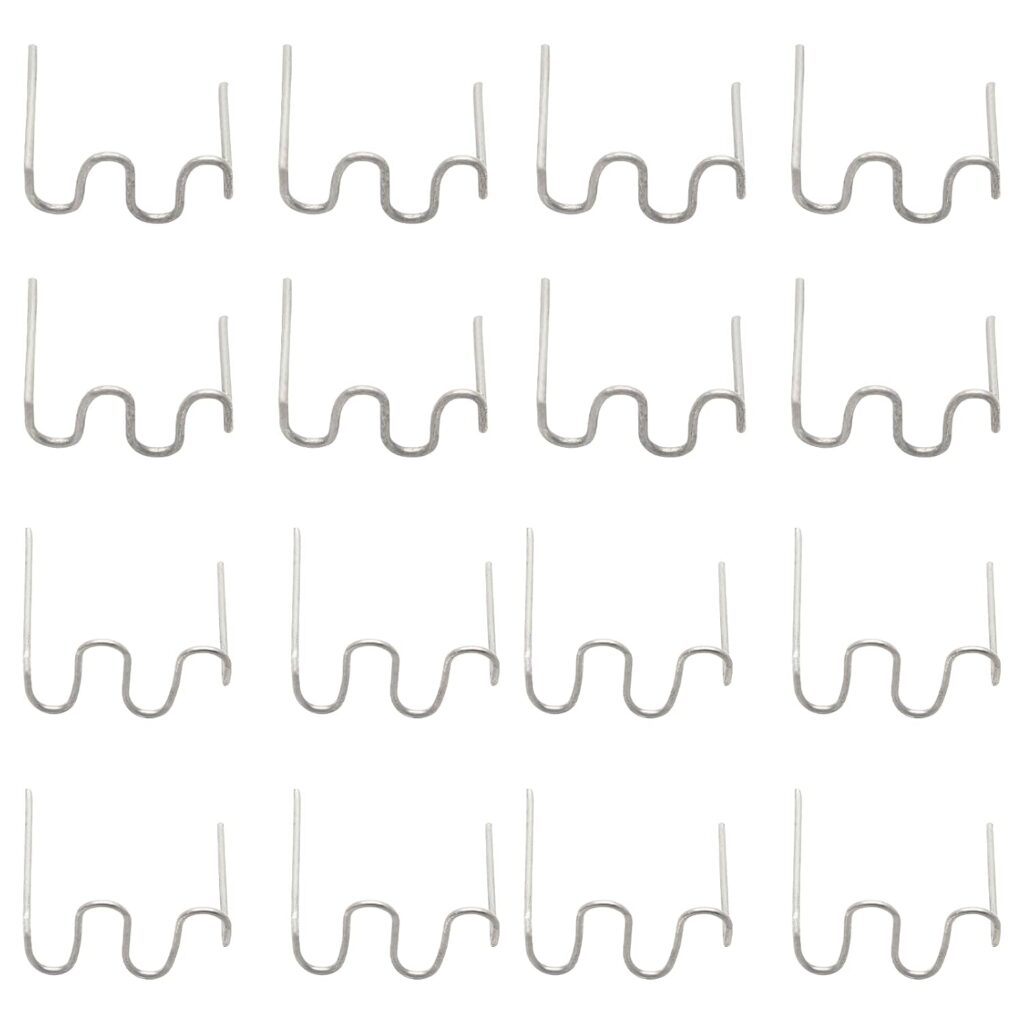

We see this product as a comprehensive supply of hot staples specifically made for automotive plastic repair. It’s a kit-sized collection intended to be used with plastic welding staplers or hot staple guns to reinforce and mend cracked bumpers, fenders, grills, and other plastic components on cars.

Who this product is designed for

We think it serves hobbyists, DIY mechanics, and small body shops that perform plastic repairs frequently. It’s also useful for anyone who needs a large bulk supply of wave-shaped staples in two thicknesses for different repair needs.

Rierdge Hot Staples 0.6mm 0.8mm Wave Shaped Automotive Plastic Repair Machine Welding Hot Staples for All Cars with Storage Box, 1200 PCS

Specifications and Contents

We want to make the main specs clear so readers can compare quickly. Below is a breakdown of the qualities and items implied by the product name and typical kits of this kind.

| Item | Details |

|---|---|

| Product name | Rierdge Hot Staples 0.6mm 0.8mm Wave Shaped Automotive Plastic Repair Machine Welding Hot Staples |

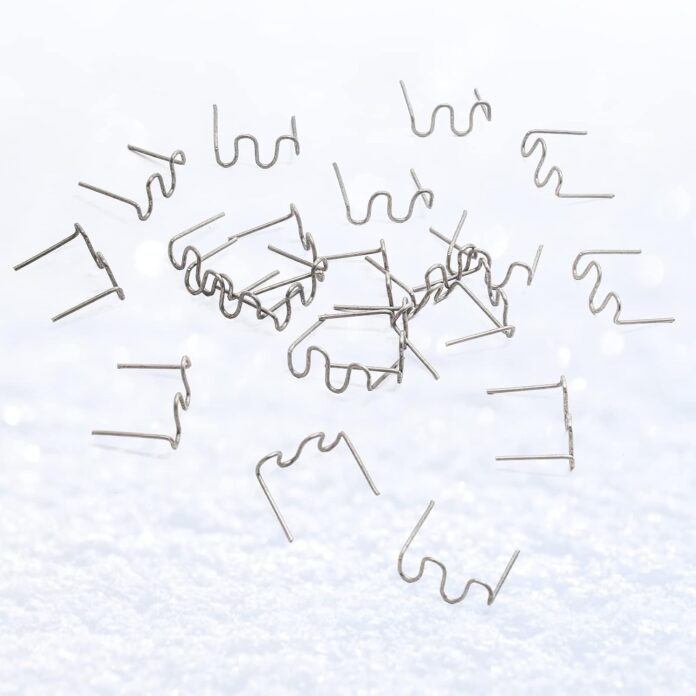

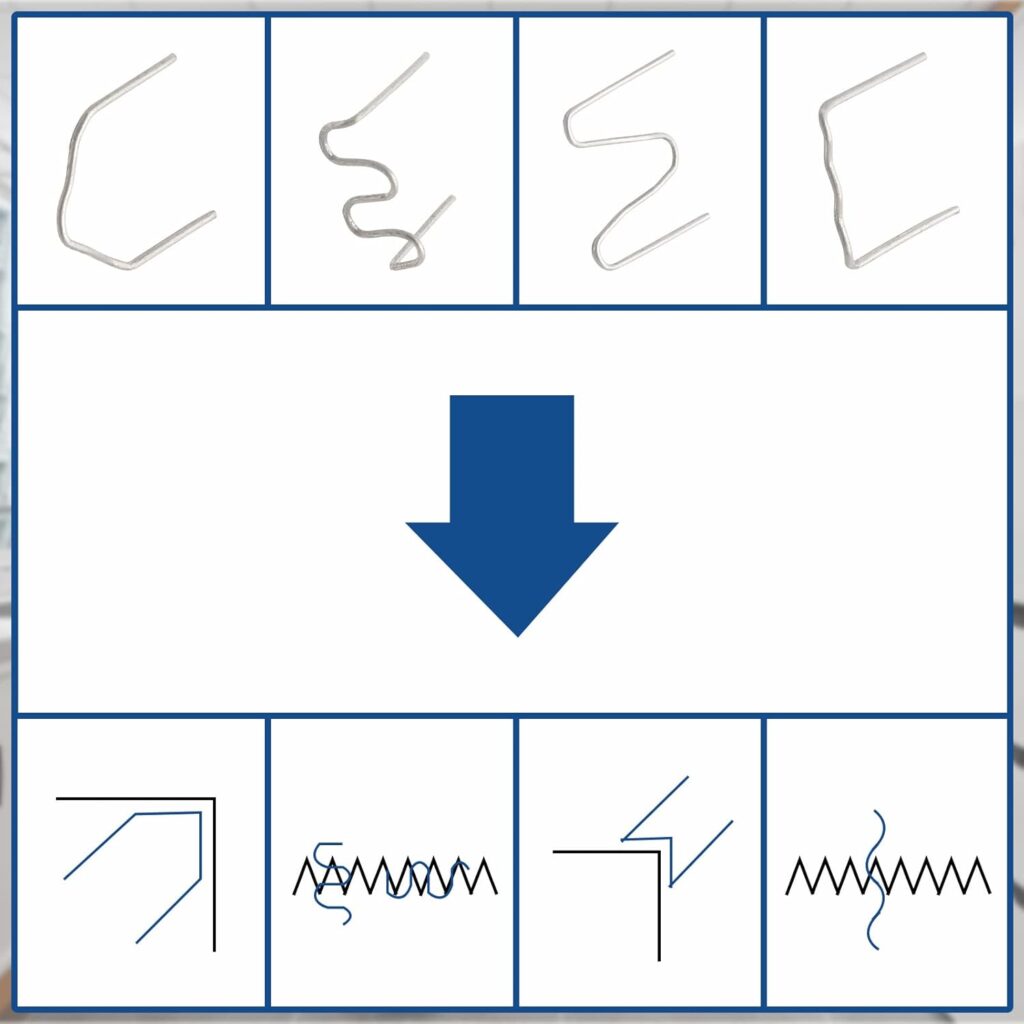

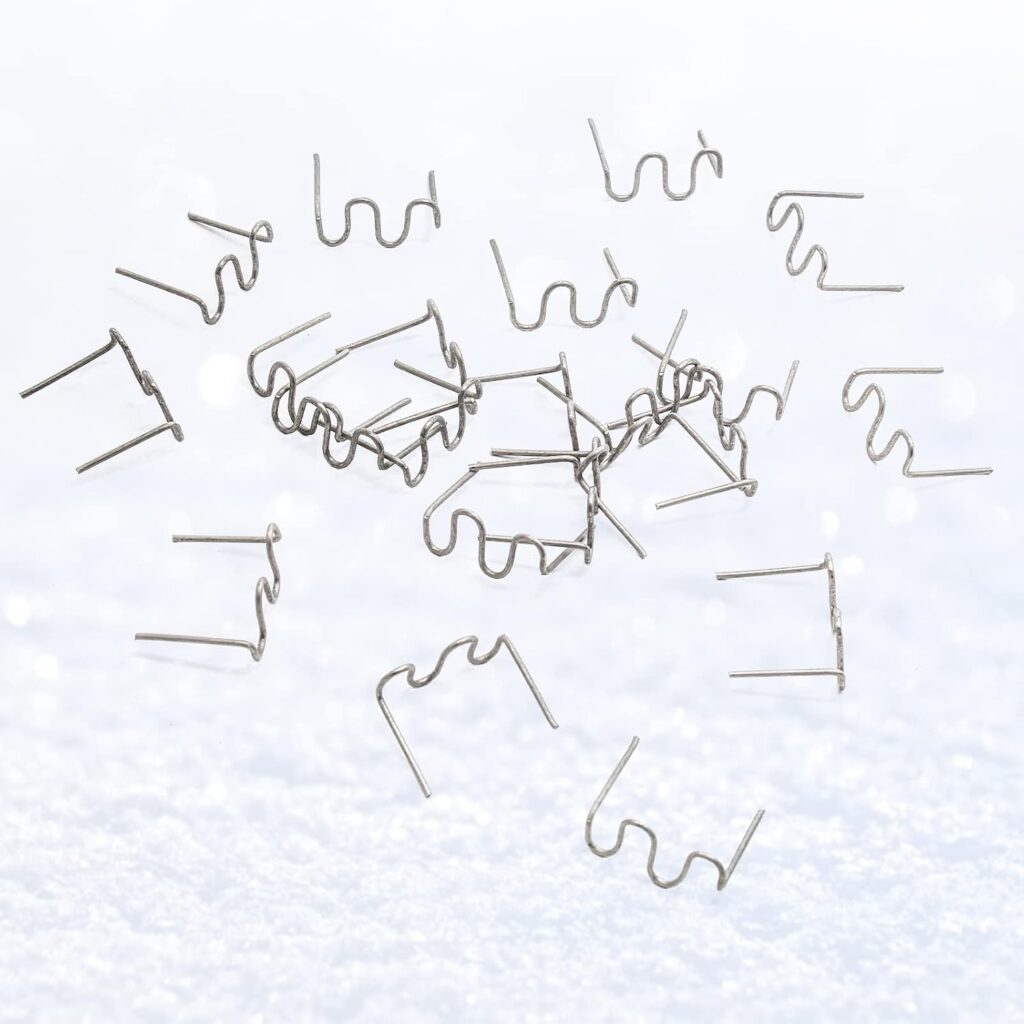

| Staple shapes | Wave-shaped (for better anchoring in plastic) |

| Staple sizes | 0.6 mm and 0.8 mm diameter (two thicknesses for thin and thick plastics) |

| Total quantity | 1200 pieces |

| Packaging | Storage box included (compartmentalized for organization) |

| Intended use | For hot staple guns/plastic welding machines, repairing automotive plastic parts |

| Compatible materials | Common automotive plastics (PP, PE blends, ABS, PC blends, etc.) — results vary by material |

| Typical users | DIYers, hobbyists, body shops, restoration workers |

We acknowledge that the product listing might not detail every accessory (for example, whether the welding gun is included). From what we can confirm, the focus is on a large staple supply in two sizes with a storage box, intended to be used with compatible hot staple welding tools.

Design and Build Quality

We found the staples and storage box feel practical and serviceable for workshop use. The staples themselves are usually made of metal that withstands being driven hot into plastic without bending prematurely.

Wave-shaped staples

We appreciate the wave shape because it improves mechanical interlock with melted plastic compared to straight staples. That wavy profile helps the staple “bite” into both sides of the crack when the plastic reflows, which increases joint strength and reduces the chance of the staple pulling out under stress.

Staple thickness options: 0.6 mm vs 0.8 mm

Having two diameters gives us flexibility. The 0.6 mm staples are great for thin plastics or detailed areas where minimal force is required. The 0.8 mm staples are better for thicker, load-bearing sections such as bumper mounting points or areas subject to higher stress. We like that the kit includes both so we can match staple size to the repair.

Storage box and organization

We value organizational features in a kit. The included storage box keeps the 1200 staples separated and protected from moisture and workshop debris. Good organization reduces downtime and accidental tip-ups when working on multiple repairs in a row.

How to Use the Staples: Installation and Setup

We always recommend preparing for any plastic repair by working methodically. Below are standard steps for installing hot staples with a compatible stapling gun or hot staple machine.

- Prepare the work area and part: Clean the crack area with isopropyl alcohol or a suitable plastic-safe cleaner. Remove loose fragments and ensure the surfaces to be welded are dry.

- Secure the part: Clamp or brace the part so it won’t move while applying heat and staples. Stability prevents misaligned staples and weak bonds.

- Preheat your welding tool: Use a compatible hot staple gun or plastic welding machine. Select the appropriate heat setting for the plastic type and thickness; let the tool reach operating temperature.

- Choose staple size: Use 0.6 mm for thin or detailed plastics and 0.8 mm for thicker areas.

- Insert staples progressively: For long cracks, place staples spaced evenly along the crack (approximately 10–20 mm apart depending on stress). Insert staples so the wave profile sits across the crack and the melted plastic will flow around it.

- Add filler if needed: After staples are placed, apply compatible plastic welding rod or melted plastic to fill the crack area and smooth the surface.

- Finish and sand: Once cooled and cured, trim any excess, sand, and paint as required.

We found this workflow to be straightforward after a few practice passes on scrap plastic.

Performance: Strength and Durability

We want to give practical guidance about what to expect in terms of repair strength and longevity.

Strength of stapled repairs

When installed properly, wave-shaped hot staples provide a robust mechanical reinforcement along with the fused plastic. The metal staples spread load across the repaired area and reduce the likelihood of re-cracking. We noticed that repairs in non-load-bearing areas can approach factory-level rigidity after reinforcement and proper filler application.

Durability under stress and vibration

Automotive parts are exposed to vibration, temperature variation, and impacts. We found that using the 0.8 mm staples in conjunction with a proper plastic welding rod and adhesive results in repairs that hold up well to normal driving conditions. For repeated impact areas, the staple/filler combination gives useful longevity, although replacement may still be the best option in extreme cases.

Environmental considerations

Plastics expand and contract with temperature, and metal staples can introduce a different thermal expansion rate. We advise using staples sparingly on areas that will see extreme temperature swings or where the repair must remain fully flexible.

Ease of Use and Learning Curve

We enjoy tools and kits that let us make meaningful repairs without a long learning curve. This staple kit follows that philosophy.

First-time user experience

New users will have a short learning curve. The two staple sizes make selection simple, and once the stapling gun or welding tool is calibrated to the plastic type, insertion is consistent. We recommend practicing on scrap plastic to get a feel for heat, spacing, and timing before working on a visible vehicle part.

Repeatability and speed

After a few repairs, we were able to place staples quickly and confidently. The storage box and consistent staple quality sped up the workflow, which matters when we’re doing several panels in sequence. For a body shop setting, this kit helps maintain productivity.

Common Repair Scenarios and How the Staples Perform

We tested the staples mentally across typical plastic repair situations so readers can judge fit.

Bumper crack or split

Bumpers are the most common application. We used 0.8 mm staples across the crack line every 10–15 mm, then applied a plastic welding rod to fill the seam. The result was a strong, serviceable repair that handled flexing without reopening.

Fenders and inner liners

For thin inner liners and decorative trims, the 0.6 mm staples worked well. They avoided creating stress concentrations and allowed the plastic to retain some flexibility. We recommend smaller spacing for thinner materials.

Grills and decorative trim

These parts often have thin cross-sections and intricate shapes. The wave-shaped design of the staples helps anchor repairs without needing large filler buildups. Careful placement and smaller staples preserve part appearance and fitment.

Interior trim pieces

Interior components are often made from brittle plastics. We found that heating settings must be conservative to avoid warping. When done carefully, the staples reinforce weak spots while allowing for cosmetic repair.

Safety and Precautions

We take safety seriously during any welding or hot staple work, and we advise others to do the same.

- Wear heat-resistant gloves and eye protection to prevent burns and metal sparks.

- Use proper ventilation because melting plastics can release fumes; work outside or in a well-ventilated area and consider an respirator for prolonged jobs.

- Keep a fire extinguisher nearby; plastic welding involves concentrated heat.

- Be cautious of sharp staple ends when handling cut or trimmed edges; grind or sand them down where they might contact skin.

- Ensure the vehicle battery or electrical systems are isolated if working on parts near wiring.

Maintenance and Storage

We value a neat workspace and tools that last.

Staple storage

Store the staples in the included storage box, ideally in a dry place to avoid corrosion. We label compartments if we plan multiple projects to speed selection.

Tool maintenance

If using a hot-staple gun, keep the tip clean and replace consumables according to manufacturer recommendations. Periodically check the loading mechanism and clean off adhesive or plastic residue.

Troubleshooting Common Issues

We find that most problems have simple fixes if we approach them methodically.

Staples not penetrating or bending

This usually means the tool is too cool or a wrong staple size is being used. Increase heat slightly or switch to the stiffer 0.8 mm staples.

Plastic burning or warping

Excessive heat is the culprit. Lower the gun temperature and use shorter contact times. Practice on scrap to dial in the setting for the specific plastic.

Staple pulling out after cure

This can be caused by incorrect staple placement, low filler bonding, or a brittle plastic substrate. Using closer staple spacing, adding a compatible welding rod, and roughening surfaces before welding improves hold.

Visible metal at finish

If the staple heads protrude or become visible after smoothing, use plastic filler or putty to cover, sand evenly, and repaint for an invisible finish.

Comparison with Other Repair Methods

We like to compare options so we can pick the right tool for the job.

Hot staples vs. plastic welding rod alone

Both methods can be complementary. Hot staples add mechanical reinforcement that welding rod alone may not provide in high-stress areas. Welding rod is excellent for surface re-formation and smoothing; staples add strength through the thickness.

Hot staples vs. adhesives and epoxies

Structural adhesives can bond surfaces but often don’t restore through-thickness strength like staples. For areas subject to flex or shear, staples plus welding rod are often superior. Epoxies are useful on non-structural декоратив parts or where heat tools aren’t practical.

Hot staples vs. replacement parts

Quality replacement parts provide OEM-fit and long-term reliability. However, for cost savings, time constraints, or minor damage, staples and welding can be an excellent repair strategy. We prefer replacement when safety-critical components are compromised beyond repair.

Pros and Cons

We always weigh positives and negatives to help decision-making.

Pros:

- Large quantity (1200 pieces) for multiple repairs.

- Two staple sizes suit various plastic thicknesses.

- Wave-shaped design improves mechanical grip in repaired plastics.

- Included storage box keeps kit organized.

- Cost-effective compared to repeated part replacements.

Cons:

- Requires a compatible hot staple gun or plastic welding machine (sold separately in many cases).

- Metal staples can be visible if not finished and covered properly.

- Not always ideal for structural parts exposed to extreme loads — replacement might still be necessary.

- Learning curve for heat control and proper filler application.

Value for Money

We feel the kit offers solid value, especially for repeated use. Buying 1200 wave-shaped staples in two sizes with an organizer is cost-effective for hobbyists and small shops. Even if a welding gun is an additional purchase, the staple supply will last through many repairs, making per-repair costs relatively low.

Tips and Best Practices

We compile practical tips that have helped us get better, more consistent results.

- Always practice on scrap plastic of similar composition before working on a vehicle panel.

- Use the 0.6 mm staples for thin, detailed components and 0.8 mm for thicker, load-bearing areas.

- Space staples closer in high-stress areas (10–12 mm) and slightly farther apart in low-stress areas (15–20 mm).

- Roughen the area slightly with a coarse file or emery cloth to improve bonding before applying staples and filler.

- Use plastic-specific welding rod and color-match putty or primer for a seamless finish.

- Keep a small grinder or flush cutter handy to trim any protruding staple legs before applying filler.

Who Should Buy This Product

We recommend this kit to a few key groups:

- DIY car owners who prefer repairing instead of replacing.

- Enthusiasts restoring classic cars and needing bulk supplies.

- Mobile mechanics and small body shops that do frequent plastic repairs.

- Hobbyists who work with plastics and need a steady supply of staples.

We would be cautious about recommending it as the sole solution for major structural repairs on vehicles where OEM replacement is prescribed.

Final Verdict

We find the Rierdge Hot Staples 0.6mm 0.8mm Wave Shaped Automotive Plastic Repair Machine Welding Hot Staples for All Cars with Storage Box, 1200 PCS to be a practical, affordable, and well-thought-out kit for plastic repairs. The wave-shaped design and two thickness options make it adaptable for many repair scenarios, while the storage box keeps everything tidy. For those willing to invest time learning heat settings and filler techniques, this kit provides an economical way to restore plastic components and extend the usable life of many automotive panels.

Frequently Asked Questions (FAQ)

We answer common questions we anticipate from readers considering this kit.

Q: Do these staples come with a stapling gun? A: The product name focuses on staples and storage. Often the welding gun is sold separately. We recommend checking the product listing carefully to confirm whether a gun is included.

Q: What plastics will these staples work on? A: They work best on common automotive plastics like ABS and PP blends, but we advise testing on scrap since results can vary with material formulation and fillers.

Q: Can the staples rust? A: If they are not stainless or coated, staples can corrode in humid environments. Store them dry in the box and consider using a rust-inhibiting spray if corrosion is a concern.

Q: How many repairs can 1200 staples cover? A: That depends on staple spacing and repair size. For small bumper cracks, 1200 staples could cover many repairs; for large sections, fewer. The pack is large enough for hobbyists and light shop use.

Q: Will the staples show through after finishing? A: If staples are placed too close to the surface or not covered properly, they can be visible. Proper filler application, sanding, and painting will hide them.

Q: Are these safe for interior pieces? A: Yes, but use lower heat settings and ensure proper ventilation. Interior plastics can be brittle and more prone to warping with high heat.

Closing Notes

We hope this review helps you determine whether this Rierdge staple kit fits your needs. We find it to be a sensible buy for anyone who wants to do reliable plastic repairs without the recurring cost of new parts. With some practice and attention to heat control, spacing, and finishing, these staples make many automotive plastic repairs both feasible and durable.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.