?Have we found a clear, durable epoxy kit that truly fits large countertop and DIY needs without harsh chemicals?

Stone Coat Countertops Clear Epoxy Resin Kit — Quick Summary

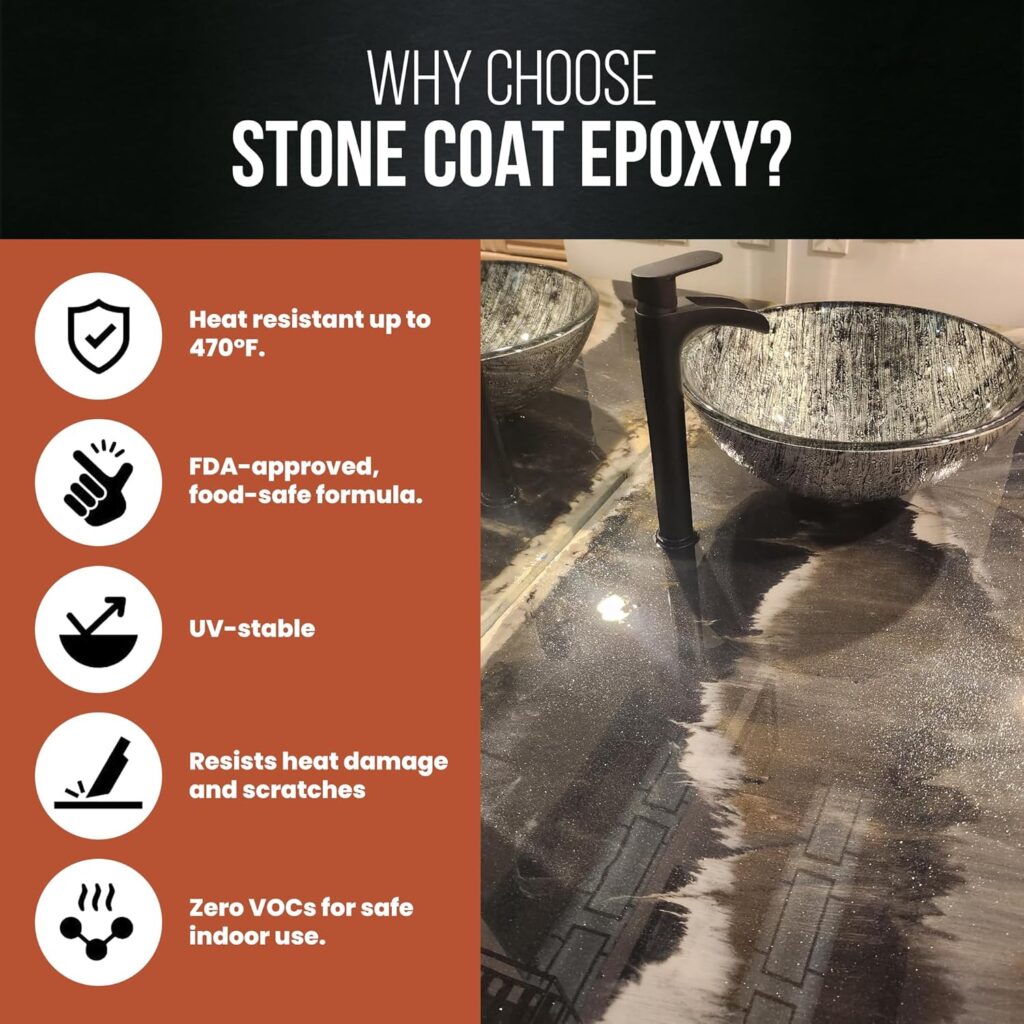

We find the Stone Coat Countertops Clear Epoxy Resin Kit (2 Gallon) to be a purpose-built option for coating kitchen countertops, tabletops, bar tops, shower walls, wood slabs, and other craft or art projects. The product promises crystal-clear results, heat resistance, UV stability, and food-safe credentials with a user-friendly 1:1 mix ratio.

What the kit includes and who it’s for

We see this kit packaged for DIYers and professionals who need a large-volume epoxy with straightforward mixing and application properties. The 2-gallon size is aimed at covering substantial surface area, making it suitable for full counters or large tables.

Key features at a glance

We appreciate the highlighted features: crystal-clear cure, heat resistance up to 470°F for incidental contact, zero VOCs, self-leveling action, UV stability, scratch resistance, and food-safe approval. These attributes position the kit for kitchen applications as well as decorative finishes where clarity and durability matter.

Stone Coat Countertops Clear Epoxy Resin Kit (2 Gallon) UV, Scratch and Heat Resistant, Food Safe, For Kitchen Countertop, Tabletop, Bar Top, Shower Walls, Wood Slabs, Other DIY Art Craft Projects

Product specifications and breakdown

We want to make specifications easy to digest, so we put the most useful information in a compact table. This helps us compare attributes at a glance and decide if the resin suits our project.

| Attribute | Specification |

|---|---|

| Product name | Stone Coat Countertops Clear Epoxy Resin Kit (2 Gallon) UV, Scratch and Heat Resistant, Food Safe |

| Mix ratio | 1:1 by volume |

| Kit sizes | ½ Gallon, 1 Gallon, 2 Gallon (this review focuses on 2 Gallon) |

| Cure appearance | Crystal clear with a glossy shine |

| Heat resistance | Up to 470°F for incidental contact |

| VOCs | Zero VOCs (USDA approved) |

| UV stability | UV stable, formulated to resist yellowing |

| Scratch resistance | High, designed for counters and tabletops |

| Food safety | Food safe when cured according to instructions |

| Self-leveling | Yes |

| Typical uses | Countertops, tabletops, bar tops, shower walls, wood slabs, craft projects |

| Additives | Compatible with mica, metallic, and glitter powders for color and effects |

How this spec table helps our decision

We find that having these specs laid out saves time when choosing between kits or planning material quantities. The table makes it easy for us to confirm that key requirements like heat resistance, UV stability, and food safety are present.

First impressions and packaging

We think packaging is an important part of the experience because it affects transport, storage, and initial handling. The 2-gallon kit typically arrives securely packed—containers are robust and labeled clearly.

Labeling and documentation

We notice clear labeling, batch information, and mixing instructions on the containers, which reduces confusion when we’re ready to work. The product comes with sufficient printed guidance for standard projects.

Container quality and handling

We find the pails or jugs strong enough for repeat handling, and the 1:1 ratio is convenient because both parts are often identical in volume. This simplifies measuring and reduces the need for special scales or pumps.

Mixing and application process

We prefer epoxy systems that simplify mixing and minimize mistakes, and this kit’s 1:1 ratio is one such simplification. Proper mixing technique still matters, and we outline step-by-step tips to improve outcomes.

Measuring and mixing

We always measure by volume in equal parts and use clean mixing paddles and containers. Mixing thoroughly for the recommended time—scraping sides and bottoms—prevents uncured spots and reduces cloudiness.

Working time and pot life

We note that pot life varies with ambient temperature. Warmer conditions shorten working time, so we plan pours and team coordination accordingly to avoid premature set. Keeping working area cool and shaded helps us maintain tack time.

Tools and accessories we recommend

We typically use a cordless drill with a mixing paddle, silicone spreaders, a small propane or butane torch for bubbles, and quality disposable cups for measuring. These basic tools help us get smooth, bubble-free surfaces.

Surface preparation and priming

We believe surface prep is the most critical phase for long-lasting epoxy coatings; without proper prep, even the best resin can fail. We describe what steps we take to create a sound substrate.

Cleanliness and decontamination

We always clean surfaces thoroughly—removing grease, oils, dust, and old finishes—so the epoxy bonds properly. A final wipe with denatured alcohol or acetone ensures a contaminant-free surface.

Sanding and profile

We typically sand glossy or finished surfaces to create mechanical adhesion, using 80–120 grit for raw wood, and 80–120 for old finishes. Vacuuming and tack-cloth wiping after sanding keeps dust from getting trapped.

Fillets, gaps, and leveling

We address gaps and seams with filler or a thin epoxy slurry before the main pour. For river tables or large voids, we layer carefully and allow base layers to cure to prevent trapping solvents or allowing entrapped bubbles to migrate.

Curing, pot life, and staging

We want predictable curing behavior so we can plan project timelines. Stone Coat’s epoxy is designed to self-level and cure reliably when mixed and applied properly.

Initial cure and tack-free time

We notice the initial tack-free time can vary but generally allows several hours before a slight tack; full cure for light use occurs over days. We allow 24–72 hours before light handling and up to 7 days for full hardness.

Full cure and heavy use

For heavy or food-contact use, we recommend waiting the full cure time specified by the manufacturer to ensure chemical resistance and hardness. We are cautious about early exposure to heat or heavy objects during this time.

Environmental factors affecting cure

We adjust our schedule for temperature and humidity; cooler conditions slow cure substantially, while high humidity can cause amine blush in some epoxies—Stone Coat’s zero VOC formulation reduces some risks, but we still control the workspace conditions when possible.

Appearance and finish quality

We want our finished surfaces to look professional—clear, glossy, and free of imperfections. Stone Coat promises crystal-clear gloss and we report on how achievable that is.

Clarity and gloss

We find the cured finish to be very clear with a high-gloss shine when applied correctly and allowed to level. Additives like mica or metallic powders create stunning visual effects without sacrificing clarity when used as intended.

Surface smoothness and bubble control

We achieve smooth results by slow, steady pours, good mixing, and using a torch or heat gun to draw out bubbles. Proper substrate sealing and pre-coating reduce bubbles arising from porous wood.

Color stability and yellowing resistance

We appreciate the UV-stable formula which resists yellowing over time better than many conventional epoxies. In sunny kitchens or bright rooms, UV stability is a major benefit for long-term aesthetics.

Heat resistance and scratch resistance in real use

For kitchen counters and bar tops, heat and scratch resistance matter for day-to-day durability. Stone Coat advertises specific metrics and we comment on real-world behavior.

Heat resistance performance

We see a heat resistance rating up to 470°F for incidental contact, which means brief contact with hot pans or trays won’t necessarily damage the surface. We still recommend trivets or hot pads for prolonged heat exposure, as extended contact can degrade many epoxy surfaces.

Scratch and abrasion resistance

We find the cured epoxy has good scratch resistance for normal household use, resisting utensils, cups, and casual wear. Heavy abrasive use or sharp impacts can still create marks, so protective routines are sensible.

Cleaning and maintenance

We maintain our epoxy surfaces with mild, non-abrasive cleaners and soft cloths; this preserves the shine and resists small surface marks. Avoiding harsh solvents or abrasive pads prevents dulling over time.

Food safety and VOC considerations

We prioritize safety when epoxy is used on food-contact surfaces. Stone Coat’s kit highlights food-safe credentials and zero VOCs.

Food-safe certification and cured resin

We note that Stone Coat claims USDA approval and food-safe status for cured epoxy when mixed and cured per instructions. We follow manufacturer instructions strictly to ensure safety—proper mix ratio, full cure time, and avoiding contamination during cure.

VOCs and working environment

We appreciate the zero VOC formulation because it lowers odor and reduces health concerns during application. Even so, we still use general ventilation and gloves while working to avoid inhaling fumes from additives or accidental skin contact.

Safety practices we follow

We always wear nitrile gloves, protective eyewear, and, if needed, a respirator suited for organic vapors when using pigments or additives. Keeping a clean workspace and following disposal guidelines keeps us safe and compliant.

Additives, coloring, and creative possibilities

One of the kit’s strengths is its compatibility with pigments and powders for creative finishes. We discuss which additives work best for specific looks.

Metallic, mica, and glitter powders

We use mica and metallic powders for shimmering swirls and depth, and glitter powders for sparkles. These additives mix well with the clear epoxy and create professional-looking finishes when blended properly.

Using dyes and liquid pigments

Liquid pigments or resin dyes can produce more solid colors but require careful testing because some pigments affect cure or clarity. We recommend small test batches before committing to a full pour.

Layering and embedded objects

We embed objects (coins, shells, wood slices) with confidence by sealing them first and then topping with epoxy, which helps prevent outgassing or trapped air. Layering for depth effects is a predictable technique with Stone Coat thanks to its self-leveling nature.

Common problems and troubleshooting

We encounter problems occasionally with epoxy projects and prefer anticipating them. Here we list common issues and how we fix them.

Bubbles trapped in the finish

Bubbles often come from mixing or porous substrates; we mitigate them by mixing slowly, letting the mix rest briefly, and using a torch or heat gun to draw bubbles out during the working time. Pre-sealing porous wood with a thin coat reduces bubble formation.

Cloudiness or amine blush

Cloudiness can result from insufficient mixing or contamination; we counter it by improving mixing technique and using clean tools. While Stone Coat’s formula is low in amine blush risk, any blush is removable with warm water and soap or by light sanding if necessary.

Incomplete cure or sticky spots

Incomplete cure usually stems from incorrect mix ratio, poor mixing, or low temperatures. We always measure carefully (1:1 by volume), mix thoroughly, and verify work area temperature to avoid sticky areas.

Yellowing over time

While Stone Coat is formulated to resist yellowing, prolonged exposure to direct sunlight can still cause changes in appearance; using additional UV-protective coatings or keeping the installation out of direct sunlight reduces risk.

Project examples and recommended uses

We like seeing practical examples to gauge what a kit can accomplish. Below are projects where this 2-gallon kit shines.

Kitchen countertops and islands

We find the kit ideal for resurfacing or creating new countertops because of its heat resistance, scratch resistance, and clear finish. The 2-gallon size often covers a full countertop with careful planning and even pour thickness.

River tables and wood slab projects

We love using this epoxy for river tables and live-edge slabs, where clarity and depth are essential to highlight wood grain and pigments. Layering and embedding are straightforward when we follow the manufacturer’s guidance.

Bar tops, tables, and shower walls

The kit works well on bar tops and tabletops needing a durable, high-gloss finish; shower walls benefit from the water resistance when properly sealed and installed. We always ensure substrate and environment are prepared for moisture exposure to maintain adhesion.

Comparing Stone Coat to other epoxies

We compare to well-known brands so we can put performance and value in context. The 1:1 mix ratio and zero VOC claim are strong differentiators.

Ease of use vs. competitors

We find the 1:1 ratio simpler than 2:1 or 3:1 systems, which reduces measuring errors. Many competing brands require more complex ratios or temperature control, making Stone Coat appealing to hobbyists.

Durability and long-term performance

Stone Coat’s UV stability and heat rating compare favorably to many consumer epoxies, though industrial or marine-grade epoxies might offer different trade-offs. For home and decorative uses, it strikes a strong balance between user-friendliness and performance.

Price and value

We often find the 2-gallon kit cost-effective relative to buying multiple smaller kits, especially for full-countertop projects. Considering coverage, performance, and the ability to add pigments, the kit tends to offer strong value for DIYers.

Cost estimation and coverage

We like to know how much product we need and how much it will cost. Coverage depends on intended thickness and surface area.

Coverage rates and thickness planning

At typical countertop thicknesses (1/8” to 1/4”), the 2-gallon kit covers a moderate-sized kitchen area or a large table when applied in a single or a few passes. For deep pours or filling large voids, multiple kits or incremental pours may be necessary.

Budgeting for tools and extras

We factor in tools (mixers, spreaders, torch), pigments, and surface prep materials in the total project budget. Purchasing small accessories can be a modest up-front investment that ensures a professional outcome.

Application tips we use to get consistent results

We prefer practical advice that keeps projects stress-free. These tips come from consistent practice and observing what makes projects succeed.

Plan pours and staging

We plan our pours to match the kit’s working time, prepping all materials and personnel in advance. Pouring in manageable sections reduces the rush and improves quality.

Temperature and humidity control

We aim for a workspace temperature between recommended ranges (often ~70–75°F) and moderate humidity to keep the cure predictable. Using portable heaters or air conditioning can be necessary in extreme seasons.

Avoiding contamination

We keep pets, children, and unnecessary airflow out of the workspace to prevent dust and debris from landing in the epoxy. Wearing hairnets and keeping the workspace immaculate reduces tiny imperfections.

Maintenance and long-term care

After investing time into a project, we want it to last. Proper maintenance prolongs the glossy finish and performance.

Cleaning routine

We clean regularly with mild soap and water or gentle, non-abrasive cleaners. Avoiding scrub pads that can dull the finish helps maintain shine.

Repairing minor scratches and flaws

Minor scratches are often buffed out with fine polishing compounds and microfiber pads, while deeper defects might require localized sanding and a thin topping coat. Stone Coat’s self-leveling nature makes spot repairs feasible.

When to recoat or reseal

We consider recoating when wear becomes visible or when a refresh is desired; a thin fresh layer restores gloss and protection. Proper surface cleaning and light sanding ensure adhesion for the new layer.

Pros and cons summary

We weigh the positive aspects against possible downsides so we can make an objective recommendation.

Pros

- Crystal-clear, high-gloss finish that highlights wood and pigments.

- 1:1 mix ratio that simplifies measuring and reduces errors.

- Zero VOCs and food-safe claims when cured properly.

- Heat-resistant up to 470°F for incidental contact.

- UV-stable and scratch-resistant formula for longevity.

- Self-leveling behavior for smooth results.

Cons

- Requires careful surface prep and mixing like other epoxies.

- Full cure times mean projects need a multi-day timeline.

- Prolonged direct heat or heavy impacts can still damage the finish.

- Larger pours or very deep fills may require additional kits or staged pours.

Frequently asked questions we field

We gather the most common questions we see in communities and answer them succinctly.

Is the cured epoxy really food safe?

Yes, when mixed and cured according to the manufacturer’s instructions, the cured resin is food safe and USDA-approved per Stone Coat’s claims. We still wait the full cure time before heavy food contact and avoid exposing unfinished or undercured surfaces to food.

Can we pour directly over wood without priming?

We typically seal porous wood with a thin epoxy coat to prevent bubbles and outgassing. Priming reduces the risk of trapped air and provides a uniform surface for subsequent topcoats.

How many square feet will a 2-gallon kit cover?

Coverage depends on desired thickness. Roughly, for a thin coat (1/16”–1/8”), the 2-gallon kit can cover a sizable tabletop or countertop; for deeper coverage or multiple coats, calculate volume vs. area carefully.

What if our epoxy gets cloudy?

Cloudiness most often arises from insufficient mixing or contamination. We resolve this by verifying mix ratio, remixing fresh batches, and ensuring clean tools. If cloudiness appears after cure, gentle sanding and a thin topcoat can restore clarity.

Final verdict and recommendation

We recommend the Stone Coat Countertops Clear Epoxy Resin Kit (2 Gallon) for DIYers and professionals seeking a large-volume, user-friendly epoxy with strong clarity, heat resistance, UV stability, and food-safe properties. Its 1:1 mix ratio, self-leveling action, and compatibility with pigments make it a flexible choice for many projects.

Who should buy it

We suggest this kit for homeowners resurfacing countertops, woodworkers creating river tables or slabs, and crafters producing durable, glossy pieces. Those who need industrial or marine-grade properties under extreme conditions should compare specs, but for most domestic and decorative uses Stone Coat performs very well.

Final tips before we start a project

We always recommend test patches, precise measurement, controlled environment, and patience through cure times. With care and preparation, we can achieve gallery-quality finishes that hold up to daily life.

If we plan on a specific project, we can help calculate coverage, recommend pigment blends, or outline a step-by-step schedule so the full 2-gallon kit is used efficiently and produces the results we want.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.