Imagine being able to effortlessly rotate and position your welding workpiece with just the touch of a button. With a welding positioner, this dream becomes a reality. In this article, we will explore the numerous advantages of utilizing a welding positioner. From increased productivity and efficiency to improved weld quality and reduced operator fatigue, a welding positioner is a game-changer in the world of welding. So, whether you are a seasoned professional or just starting out, read on to discover how this innovative tool can revolutionize your welding experience.

Increased Efficiency and Productivity

Precise and Consistent Welding

When using a welding positioner, you can expect precise and consistent welding results. The rotating and tilting capabilities of the positioner allow for precise control over the welding process, ensuring that each weld is executed with the utmost accuracy. This precision eliminates the need for manual adjustments and reduces the chances of human error, resulting in superior weld quality and overall productivity.

Reduced Welding Time

One of the key advantages of using a welding positioner is the significant reduction in welding time. By automating the rotation and tilt of the workpiece, the positioner enables the welder to access all angles and positions without the need for manual manipulation. This streamlined process eliminates downtime for repositioning and allows for continuous welding, ultimately saving valuable time and increasing overall efficiency.

Ease of Use and Reduce Operator Fatigue

Welding can be a physically demanding task, requiring operators to hold heavy equipment and maintain precise movements for extended periods. However, with a welding positioner, the operator can easily position the workpiece in the most convenient and comfortable orientation. The automated rotation and tilt functions alleviate the strain on the welder, reducing fatigue and improving their overall comfort. This, in turn, leads to increased productivity and a more enjoyable working experience.

Ability to Weld Complex Shapes and Positions

The flexibility offered by a welding positioner allows for the welding of complex shapes and positions that would otherwise be challenging to achieve. With the ability to rotate and tilt the workpiece, the positioner opens up possibilities for welding in tight corners, difficult-to-reach areas, and irregular shapes. This versatility not only expands the range of projects that can be undertaken but also enhances the overall quality and strength of the welds.

Improved Weld Quality

Better Weld Penetration and Fusion

With a welding positioner, you can achieve better weld penetration and fusion. The controlled rotation and tilt of the workpiece ensure that the heat is evenly distributed, allowing for deeper penetration and improved fusion between the base metal and the filler material. This results in stronger, more durable welds that are less prone to defects or failures.

Reduced Heat Distortion

Heat distortion is a common challenge in welding, especially when working with thick materials or complex shapes. However, using a welding positioner mitigates this issue by providing consistent heat distribution throughout the weld area. The controlled rotation and tilt prevent excessive heat buildup in a specific region, minimizing the risk of distortion and preserving the structural integrity of the workpiece.

Higher Welding Speeds

A welding positioner enables higher welding speeds, contributing to improved productivity and time-saving benefits. With the rotation and tilt features, the welder can access different angles and positions without the need for constant repositioning. This uninterrupted welding process allows for faster completion of projects, and by extension, increases the overall output and efficiency of the welding operation.

Enhanced Weld Aesthetics

In addition to the mechanical advantages, a welding positioner also enhances the aesthetics of the welds. The controlled and consistent rotation and tilt ensure that the weld bead is evenly distributed and smoothly formed, resulting in a visually appealing finish. Improved weld aesthetics not only contribute to the overall quality of the product but also enhance its marketability and customer satisfaction.

Enhanced Safety

Minimized Exposure to Fumes and Sparks

Welding produces hazardous fumes and sparks that can pose health and safety risks to the operators. However, using a welding positioner can help minimize exposure to these hazards. By automating the rotation and tilt functions, the operator can maintain a safe distance from the welding arc and the resulting fumes, reducing the risk of inhalation and potential respiratory issues. Additionally, the positioner can be equipped with extraction systems to further ensure a safe working environment.

Reduced Risk of Operator Injury

Manual manipulation of heavy workpieces and prolonged periods of holding welding equipment can lead to operator injuries, such as strains, sprains, or accidents. By utilizing a welding positioner, the physical strain on the operator is significantly reduced, minimizing the risk of musculoskeletal injuries. The automated rotation and tilt functions allow for easy and precise positioning of the workpiece, eliminating the need for awkward and strenuous movements, thus promoting a safer working environment.

Improved Ergonomics

Ergonomics plays a crucial role in ensuring the health and well-being of welding operators. With a welding positioner, operators can maintain proper posture and positioning, reducing the risk of discomfort, fatigue, and long-term musculoskeletal issues. By providing a comfortable and ergonomic working environment, a welding positioner enhances operator safety and productivity.

Cost Savings

Reduced Labor Costs

Using a welding positioner can lead to significant cost savings by reducing labor requirements. The automated rotation and tilt functions eliminate the need for manual repositioning of the workpiece, allowing a single operator to handle the welding process more efficiently. This eliminates the need for additional labor or specialized skill sets, reducing labor costs and optimizing resource allocation.

Decreased Equipment Wear and Tear

Manual welding involves frequent repositioning of the workpiece, causing wear and tear on equipment such as welding torches, cables, and fixtures. However, with a welding positioner, the need for constant equipment adjustments is eliminated, resulting in reduced wear and tear. This prolongs the lifespan of welding equipment, reducing maintenance and replacement costs over time.

Less Material Waste

Precise and consistent welding, facilitated by a welding positioner, reduces material waste. Automated rotation and tilt functions allow for optimal welding angles and positions, minimizing the chances of weld defects or deviations that would require rework or material scrapping. With less material waste, overall project costs are reduced, leading to significant cost savings in the long run.

Increased Versatility

Accommodating Different Workpiece Sizes and Shapes

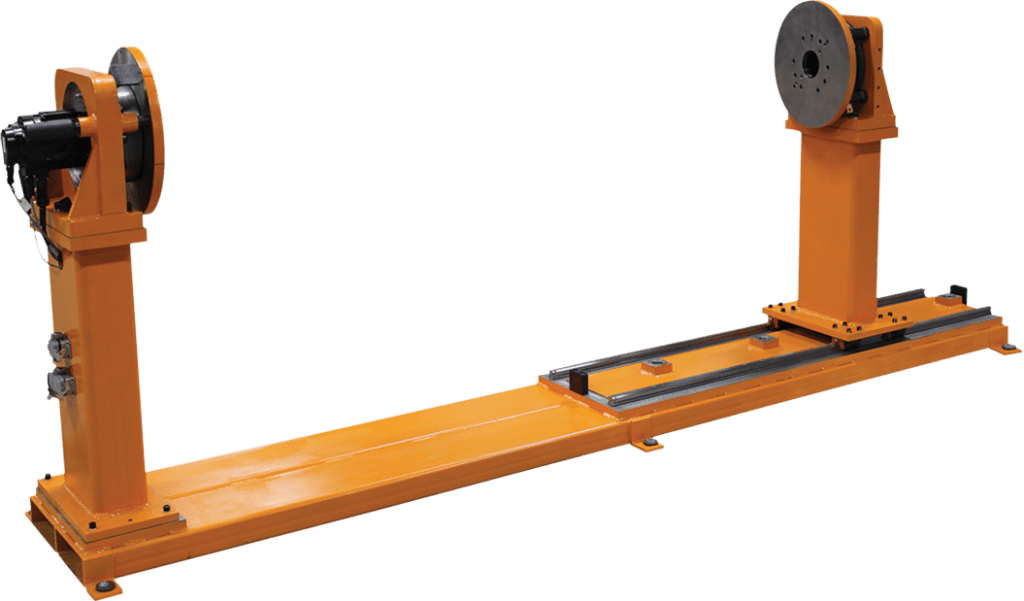

Welding positioners are designed to accommodate a wide range of workpiece sizes and shapes. Whether you are working with small, intricate components or large, bulky structures, a welding positioner can easily handle them. The adjustable grips and fixtures, combined with the rotation and tilt capabilities, ensure that the workpiece is securely held in the desired orientation, allowing for seamless welding regardless of its size or shape.

Multiple Welding Positioning Options

A welding positioner offers multiple positioning options, enabling welders to easily access different angles and positions. This versatility is particularly beneficial when working on complex projects that require welding in various orientations. Whether it’s horizontal, vertical, or even overhead welding, a welding positioner provides the necessary flexibility to ensure optimal weld quality and accessibility.

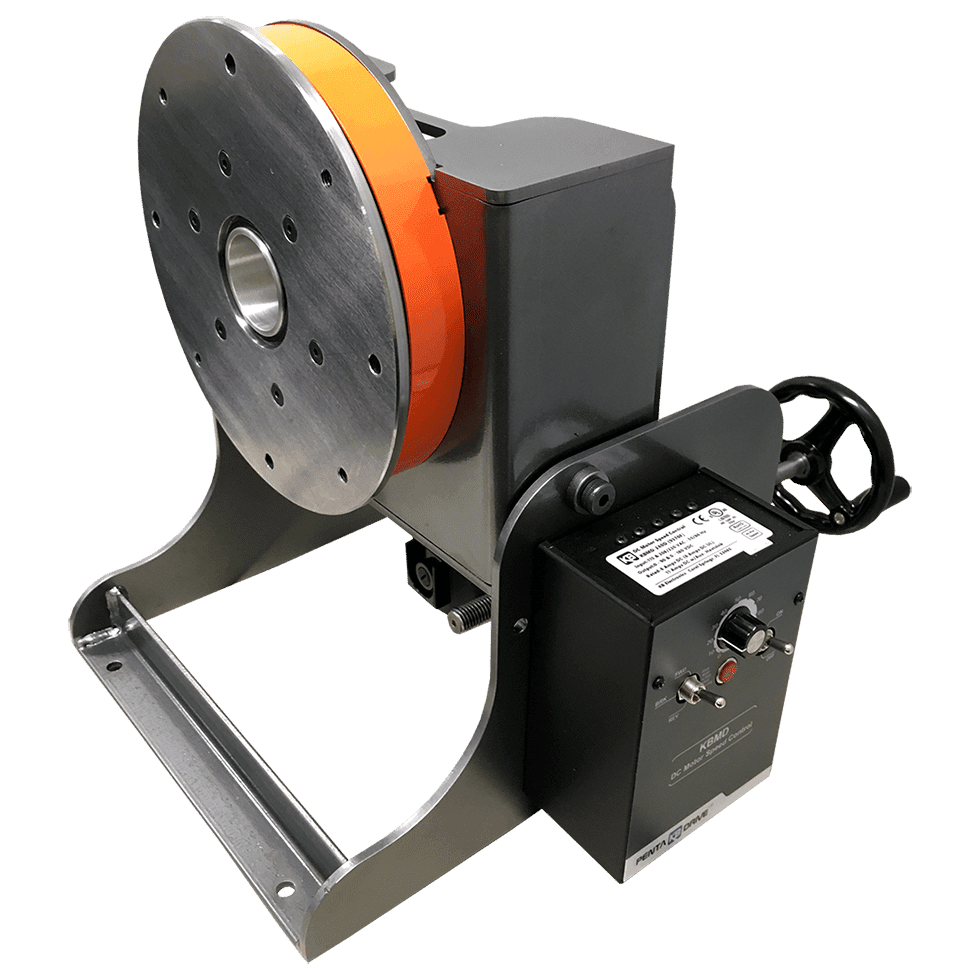

Ability to Rotate and Tilt Workpieces

The ability to rotate and tilt workpieces is a key advantage of using a welding positioner. By automating these movements, the positioner allows for precise control over the positioning of the workpiece during welding. This capability makes it easier to achieve consistent and accurate welds, even when dealing with challenging joint configurations or hard-to-reach areas. The rotational and tilting features offer the welder enhanced control and flexibility, resulting in superior weld quality.

Flexibility in Welding Processes

Compatibility with Various Welding Techniques

A welding positioner is compatible with various welding techniques, making it a versatile solution for different welding applications. Whether you are using TIG (tungsten inert gas), MIG (metal inert gas), or even automated welding processes, a welding positioner can accommodate and enhance each technique. The compatibility with different techniques expands the range of projects that can be undertaken, catering to the diverse needs of welding operations.

Ability to Weld in Different Configurations and Joints

Welding positioners offer the ability to weld in different configurations and joint types, providing flexibility in welding applications. From linear joints to circumferential or angular joints, a welding positioner can effectively handle them all. The rotational and tilting capabilities allow welders to maneuver and position the workpiece to achieve optimal access and weld quality, regardless of the specific joint configuration.

Improved Weld Inspection and Testing

Better Access for Non-Destructive Testing

Non-destructive testing (NDT) is an essential part of ensuring weld quality and structural integrity. A welding positioner provides better accessibility for NDT procedures by allowing inspectors to examine the welds from different angles and positions. This enhanced access facilitates thorough inspection, enabling potential welding defects or flaws to be identified and rectified before they result in structural failures or compromised weld quality.

Easier Inspection of Weld Quality

Inspecting weld quality becomes easier when using a welding positioner. The controlled rotation and tilt of the workpiece allow inspecting the entire weld joint without difficulties. This comprehensive inspection capability ensures that the welds adhere to the required standards and specifications, guaranteeing the overall quality and strength of the finished product.

Ease of Weld Seam Tracking

Assistance with Weld Seam Tracking

Weld seam tracking is a critical aspect of ensuring accurate welding along the desired joint or seam. Welding positioners can be integrated with seam tracking systems to automate this process. By utilizing sensors and advanced tracking algorithms, these systems guide the welding torch along the weld seam, compensating for any variations or deviations. This automation reduces the need for manual monitoring and adjustment, resulting in consistent and precise welds.

Automated Welding with Seam Tracking Systems

Seam tracking systems, when combined with a welding positioner, enable automated welding, thereby further enhancing efficiency and productivity. The seam tracking technology detects and tracks the weld joint, allowing the welding process to be seamlessly automated. This automation eliminates the need for constant manual control and adjustment, enabling the welder to focus on other tasks and optimizing overall productivity.

Reduced Welding Operator Skill Requirements

Minimized Skill Level Requirements

Utilizing a welding positioner reduces the required skill level for welding operators. The automation and control offered by the positioner streamline the welding process, minimizing the need for specialized techniques or extensive experience. Even less experienced operators can achieve high-quality welds with precision and consistency, reducing the reliance on highly skilled, specialized personnel and opening opportunities for less experienced individuals to contribute to welding operations.

Reduced Training Time

The simplified welding process facilitated by a welding positioner leads to reduced training time for operators. The automated rotation and tilt of the workpiece eliminate the need for complex manual manipulations or specific welding techniques. With a shorter learning curve, new operators can quickly grasp the concepts and techniques, ensuring a faster integration into the welding workflow and reducing the time and resources required for comprehensive training.

Increased Welding Consistency

Consistency in Weld Parameters

Achieving consistent weld parameters is crucial for ensuring uniformity and strength across the welds. A welding positioner greatly enhances this consistency by providing precise and accurate control over the welding process. From the speed of rotation to the tilt angle, every parameter can be precisely controlled and replicated throughout the welding operation. This consistency leads to uniform weld quality and reduces the occurrence of defects or inconsistencies.

Uniform Heat Distribution

A welding positioner promotes uniform heat distribution during the welding process. The controlled rotation and tilt ensure that the heat is evenly distributed across the workpiece, preventing localized overheating or insufficient heat penetration. This uniform heat distribution contributes to the overall strength and quality of the welds, minimizing the risk of defects or failures. By promoting uniformity, a welding positioner significantly enhances the reliability and longevity of the welded components.

In conclusion, the advantages of using a welding positioner are numerous and impactful. From increased efficiency and productivity to enhanced safety and reduced costs, a positioner offers a multitude of benefits to welding operations. With precise and consistent welding, improved weld quality, and increased versatility, a welding positioner proves to be a valuable asset in the arsenal of any modern welder. By embracing this technology, welding processes are streamlined, operator skills are optimized, and overall welding operations are elevated to new levels of excellence.