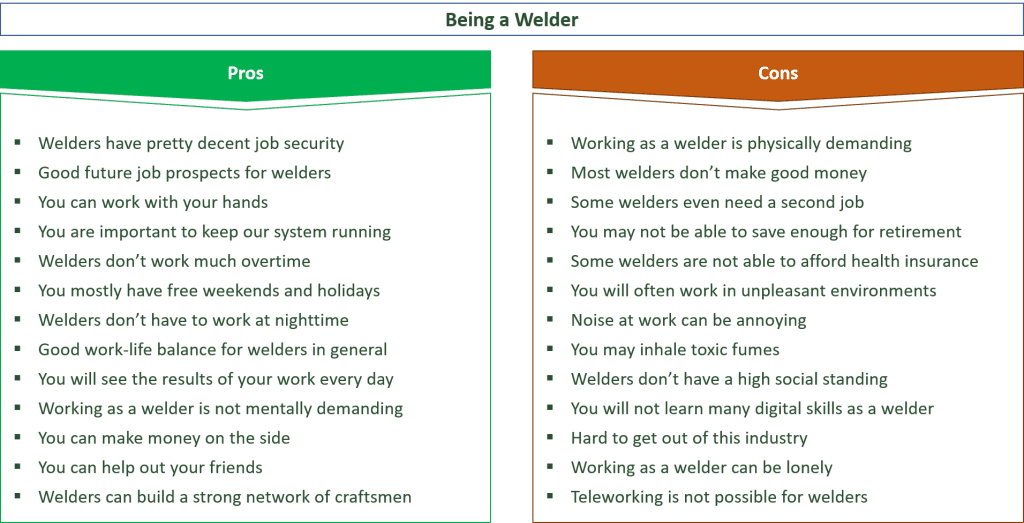

If you’ve ever considered a career in welding, weighing the pros and cons before diving into the industry is essential.

From the satisfaction of bringing metal to life with your skilled hands to the physical demands and potential health risks, being a welder offers a unique blend of advantages and challenges.

In this article, we’ll explore the positive and negative aspects of this dynamic profession, giving you a comprehensive understanding of what it truly means to be a welder.

Job Security

High demand for skilled welders

Being a skilled welder can provide you with excellent job security. The demand for skilled welders is consistently high due to the need for their services in various industries such as construction, manufacturing, oil and gas, and automotive.

From building structures to repairing machinery, skilled welders are essential to many industries.

Stable employment opportunities

With the high demand for skilled welders, stable employment opportunities are often available. As long as there are industries that rely on welding, you can feel confident knowing that there will be a steady stream of job openings.

Welding is a specialized skill, and those who possess it are often in high demand, making it less likely for you to experience long periods of unemployment.

Income Potential

Attractive salary

One of the significant advantages of being a welder is the attractive salary that comes with the profession. Skilled welders can command competitive pay rates due to the specialized nature of their work.

Welders earn more than other trades, and their income can increase with more experience and expertise. This higher income potential can provide you with a comfortable quality of life and financial stability.

Opportunities for overtime pay

Welders often have the opportunity for overtime pay, which can significantly increase their earnings. Many welding projects require strict deadlines and quick turnaround times, which may lead to extended work hours.

Additionally, some industries, such as construction and manufacturing, may offer financial incentives for working overtime. This additional income can be an excellent advantage for earning more money.

Potential for career advancement

While welding may not have as many vertical career growth options as other professions, there are still opportunities for advancement.

As you gain more experience and skill in welding, you can take on more complex projects or even move into supervisory roles. Additionally, you may have the chance to specialize in a specific type of welding, further increasing your value and potential for career growth.

Versatile Skills

Transferable skills across industries

One of the benefits of being a welder is that the skills you acquire are highly transferable across various industries. Welding techniques and principles remain relatively consistent, regardless of your industry. This means that your welding skills can still be valuable in different sectors if you seek a career change. Applying your expertise in different industries allows for greater flexibility and adaptability in your career.

Opportunities to work on diverse projects

You can expect to work on a wide range of projects as a welder. The possibilities are endless, from constructing buildings and bridges to creating intricate metal designs. This diversity in projects keeps the work interesting and allows you to develop new skills and broaden your knowledge base. Whether you prefer large-scale projects or enjoy the intricacies of custom metalwork, welding offers a range of opportunities that can keep you engaged and motivated.

Short Training Period

Quick entry into the profession

Becoming a welder involves a relatively short training period compared to many other professions. While obtaining a formal education or completing an apprenticeship is beneficial for acquiring the necessary skills and knowledge, it can often be completed within a year or two.

This means you can enter the welding profession and start earning a steady income in a relatively short time, making it an attractive option for those eager to begin their careers promptly.

Lower education requirements compared to other jobs

In addition to the short training period, welding has lower education requirements than many other jobs. While a high school diploma or equivalent is typically preferred, formal academic degrees are not always mandatory.

This accessibility makes welding a viable career choice for individuals who may not have the means or desire to pursue higher education. With the proper training and experience, you can establish yourself as a skilled welder and build a successful career.

Physical Demands

Physically demanding work environment

It’s important to note that being a welder involves working in a physically demanding environment.

Welders often spend long hours on their feet, performing repetitive tasks. The nature of the work may require bending, stooping, and working in awkward positions. You must have physical strength, stamina, and good overall fitness to perform the job effectively.

Risk of injuries and health issues

Due to the nature of welding work, there is a risk of injuries and health issues. Welders are exposed to various hazards, including molten metal, sparks, and flying debris.

They may suffer burns, eye injuries, respiratory problems, or even long-term health effects without proper safety precautions. It is essential to follow strict safety protocols, wear appropriate protective gear, and undergo regular medical check-ups to minimize these risks.

Exposure to Hazards

Working with hazardous materials

Welders often work with hazardous materials such as gases, chemicals, and metals. These materials can pose health risks if not handled properly.

For example, welding fumes generated during the process can contain toxic substances, which, when inhaled, can lead to respiratory issues. Welders must be aware of the potential hazards and follow appropriate safety measures to protect themselves and others in the work environment.

Exposure to high temperatures and fumes

Welding typically involves working with high temperatures, which can be physically challenging and increase the risk of burns. The heat generated during welding also produces fumes, which can be harmful if inhaled over an extended period.

Welders must have proper ventilation and wear respiratory protective equipment to minimize exposure to these fumes and maintain their health and well-being.

Work Environment

Varied work settings: indoors, outdoors, and heights

Another advantage of being a welder is the varied work settings you may encounter. Depending on the project and industry, you may work indoors, outdoors, or even at heights.

This diversity can provide a refreshing change of scenery and allow you to experience different work environments. Whether you prefer the controlled environment of a workshop or enjoy the challenges of working outdoors, welding offers a versatile range of work settings.

Potential for travel and working in different locations

In addition to varied work settings, being a welder can offer the opportunity to travel and work in different locations.

Specific welding projects may require traveling to different cities, states, or countries. This prospect can be exciting for those who enjoy exploring new places and experiencing different cultures. Traveling for work can broaden your horizons and provide you with unique experiences along the way.

Limited Career Progression

Limited options for vertical career growth

While there are opportunities for career advancement in welding, it is worth noting that the options for vertical career growth may be limited compared to other professions.

Welding typically follows a linear career path, with progression often requiring increased experience and specialization rather than climbing a corporate ladder. However, with dedication, continuous skill development, and seeking opportunities for professional growth, you can still excel in your welding career.

Lack of specialized roles

Sometimes, the lack of specialized roles within the welding profession may limit your career progression options. Unlike specific industries that offer a multitude of specialized roles or areas of expertise, welding generally requires a certain level of versatility.

While specialization is possible, the range of specialized roles within the welding field may be limited. Assessing your long-term goals and determining if the potential for specialized roles aligns with your career aspirations is essential.

Risk of Automation

Advancements in welding technology may reduce job opportunities

As with many industries, technological advancements can pose a potential risk to job opportunities. Automation and robotic welding technologies have become more advanced, increasing efficiency and productivity.

While these technologies can be beneficial in specific contexts, they may also reduce the demand for manual welding labor. It is crucial for welders to stay updated with the latest technological advancements and continuously develop their skills to remain competitive in the job market.

Need to update skills to adapt to technological changes continuously

To mitigate the risk of automation and stay relevant in the field, welders must continuously update their skills and adapt to technological changes.

Learning new welding techniques and staying abreast of industry advancements can help you remain competitive and ensure steady job opportunities. Embracing new technology and seeking training or certification programs can enhance your employability and help you thrive in a changing work environment.

Issue of Long-Term Health effects

Exposure to welding fumes linked to potential health problems

Exposure to welding fumes has been associated with potential health problems, particularly when proper safety measures are not followed. Inhaling welding fumes can lead to respiratory issues, such as chronic bronchitis or occupational asthma.

Welders must take the necessary precautions, such as wearing appropriate respiratory protective equipment, working in well-ventilated areas, and undergoing regular medical check-ups to monitor their respiratory health.

Challenges of long-term respiratory health

Long-term exposure to welding fumes can pose challenges to respiratory health. Welders continually exposed to these fumes without adequate protection may develop chronic respiratory conditions that can impact their quality of life.

Welders need to prioritize their health by practicing proper safety measures, seeking medical attention when needed, and managing any respiratory symptoms promptly. Regular check-ups and monitoring can help mitigate the long-term effects of welding on their respiratory health.

In conclusion, being a welder offers advantages, such as job security, attractive income potential, and the opportunity to develop versatile skills. However, it is essential to consider the physical demands, exposure to hazards, and potential health effects associated with the profession.

By prioritizing safety, continuous skill development, and adapting to technological changes, you can navigate the challenges and enjoy a fulfilling and successful career in welding.