In the world of welding, protecting oneself is of utmost importance, and a crucial part of any welder’s equipment is the welding helmet. But did you know that there are three different styles of welding helmets? These styles offer different features and advantages, ensuring that welders can choose the one that best suits their needs. Whether it’s the traditional flip-up helmet, the popular auto-darkening helmet, or the innovative respirator helmet, each style brings its own unique benefits and allows welders to work with safety and comfort. Let’s take a closer look at these three distinct styles of welding helmets and discover which one might be the perfect fit for your welding needs.

This image is property of blog.safetyglassesusa.com.

Standard Welding Helmet

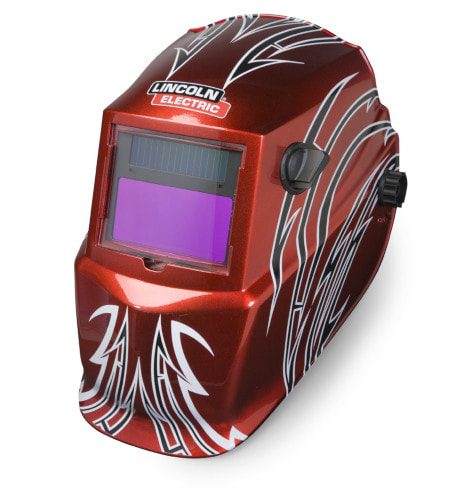

Auto-Darkening Helmet

When it comes to welding, safety is always a top priority. That’s why a welding helmet is an essential piece of equipment for any welder. One popular style of welding helmet is the standard welding helmet, which comes in various types. One of the most convenient and efficient types is the auto-darkening helmet.

The auto-darkening helmet is designed to automatically adjust the shade of the lens based on the intensity of the welding arc. This means that when you strike an arc, the lens darkens to protect your eyes from harmful ultraviolet (UV) and infrared (IR) rays. As soon as the arc is extinguished, the lens returns to its normal state, providing you with clear visibility to inspect your work or move on to the next task without having to remove your helmet.

The benefits of using an auto-darkening helmet are numerous. Firstly, it eliminates the need to constantly flip your helmet up and down between welding and non-welding activities. This saves time and allows you to focus on your work, increasing productivity. Additionally, this type of helmet provides consistent protection by ensuring your eyes are shielded from the harmful rays at all times, resulting in improved safety and reduced eye strain.

Passive Lens Helmet

Another type of standard welding helmet is the passive lens helmet. Unlike the auto-darkening helmet, the passive lens helmet features a fixed shade lens that does not automatically adjust to the welding arc. Instead, you have to manually lift the helmet to see your work during non-welding activities.

While the passive lens helmet may not offer the same level of convenience as the auto-darkening helmet, it still provides reliable protection. It is often preferred by experienced welders who have a consistent understanding of the shade they need for their specific welding tasks. This style of helmet is also more affordable compared to the auto-darkening option, making it a popular choice for welders on a budget.

Despite the need for manual adjustment, the passive lens helmet offers some advantages. One benefit is its durability. With fewer moving parts, this type of helmet tends to be more robust and less prone to malfunctioning. Additionally, the fixed shade lens provides a stable shade level, meaning you can trust that your eyes are adequately shielded at all times.

Flip-Up Welding Helmet

Design and Functionality

The flip-up welding helmet is another style of welding helmet that offers unique features and benefits. As the name suggests, this helmet design allows the entire front portion of the helmet to be flipped up, providing welders with the option to alternate between a welding mode and a non-welding mode without having to remove the entire helmet.

The flip-up design typically consists of a hinge at the top of the helmet, allowing the front visor to be easily lifted. This allows for better visibility during non-welding tasks, such as grinding or chipping off slag, while still providing eye protection. When it’s time to resume welding, simply flip the visor back down, securing it in place, and you’re ready to go.

Benefits and Limitations

The primary benefit of using a flip-up welding helmet is the versatility it provides. Welders who frequently transition between welding and non-welding activities can benefit greatly from this style of helmet. It eliminates the need to constantly put on and take off the helmet, saving time and effort. Additionally, the flip-up design allows for better ventilation during non-welding tasks, reducing heat build-up and discomfort.

However, it is important to note that flip-up welding helmets may not offer the same level of eye protection as other styles. Since the front visor can be lifted, there is a slightly higher risk of accidental exposure to welding arcs. As a result, it is crucial to ensure that the visor is securely latched in the down position before beginning any welding activity.

This image is property of waterwelders.com.

PAPR Welding Helmet

Powered Air Purifying Respirator (PAPR)

Welding involves the release of hazardous fumes and particles, which can pose serious health risks if inhaled. To address this concern, a PAPR welding helmet combines a respiratory protection system known as a Powered Air Purifying Respirator (PAPR) with an integrated welding helmet.

A PAPR system consists of a helmet with a built-in respirator that filters the air and supplies it to the welder through a hose connected to a fan-powered unit. The fan helps to create positive pressure inside the helmet, preventing the entry of contaminated air and ensuring a constant flow of clean air to the welder’s breathing zone.

Integrated Welding Helmet

The PAPR welding helmet integrates the PAPR system with a welding helmet, providing welders with both respiratory protection and eye protection in one device. This eliminates the need for separate respirators and welding helmets, streamlining the welding process.

The integrated welding helmet usually features an auto-darkening lens, similar to the standard auto-darkening helmet mentioned earlier. This technology ensures that the welder’s eyes are adequately shielded from welding arcs, while the PAPR system takes care of filtering the surrounding air to protect the welder’s respiratory system.

Advantages and Considerations

The primary advantage of using a PAPR welding helmet is the comprehensive protection it offers. Welders can work confidently knowing that they are shielded from harmful fumes, particles, and welding arcs, reducing their risk of respiratory and eye-related health issues. The PAPR system also helps to improve overall comfort by providing a continuous supply of fresh, filtered air, reducing fatigue during long welding sessions.

However, there are a few considerations when opting for a PAPR welding helmet. This style of helmet tends to be bulkier and heavier due to the integrated PAPR system, which may cause some discomfort or restrict movement for certain individuals. Additionally, the maintenance and cost of replacing filters and batteries for the PAPR unit should be taken into account.

In conclusion, when it comes to welding helmets, there are three different styles to consider: the standard welding helmet (including auto-darkening and passive lens options), the flip-up welding helmet, and the PAPR welding helmet. Each style offers its own unique features and benefits, catering to different preferences and welding needs. By understanding the advantages and considerations of each style, welders can make an informed decision to ensure their safety and comfort while working.

This image is property of waterwelders.com.