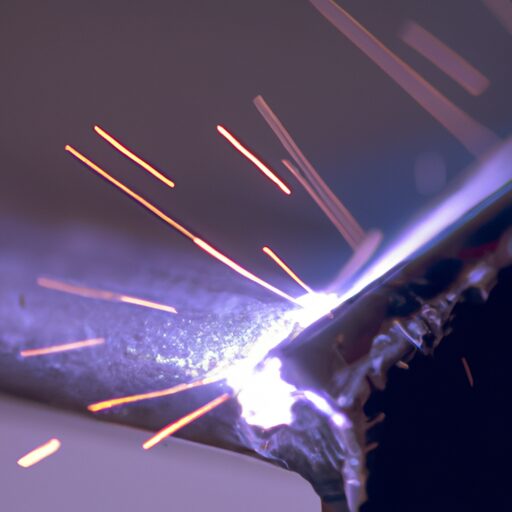

Post-weld heat treatment plays a crucial role in ensuring the structural integrity and performance of welded components. By subjecting the welded joints to controlled heating and cooling processes, post-weld heat treatment helps to relieve residual stresses, improve mechanical properties, and enhance corrosion resistance. This article explores the significance of post-weld heat treatment in enhancing the durability and longevity of welded structures, shedding light on the various benefits it offers.

Ensures Optimal Microstructure

Controls Grain Growth

Post-weld heat treatment plays a crucial role in controlling grain growth in welded materials. During the welding process, the heat-affected zone experiences rapid heating and cooling, which can lead to the formation of coarse-grained microstructures. These coarse grains can significantly affect the mechanical properties of the welded component. However, by subjecting the welded material to a specific heat treatment regimen, we can effectively control and refine the grain size, resulting in a more uniform and desirable microstructure.

Controls Phase Transformation

Another essential aspect of post-weld heat treatment is its ability to control phase transformation in welded materials. During the welding process, various phases may form, such as martensite, ferrite, or austenite, depending on the alloy composition and welding conditions. However, these phases may not be ideal for the desired mechanical properties or corrosion resistance. Through post-weld heat treatment, we can modify the phase transformation kinetics, ensuring the formation of more stable and desirable phases, thus enhancing the overall performance of the welded component.

Improves Mechanical Properties

Post-weld heat treatment is a key factor in enhancing the mechanical properties of welded materials. Welding introduces residual stresses and impurities, which can adversely affect the strength, ductility, and toughness of the weld joint. By subjecting the welded component to an appropriate heat treatment process, we can relieve these residual stresses, eliminate impurities, and optimize the material’s mechanical properties. This can lead to improved fatigue resistance, increased toughness, and better overall performance of the welded structure.

Relieves Residual Stresses

Minimizes Distortion

One of the primary benefits of post-weld heat treatment is its ability to minimize distortion in welded structures. Welding involves localized heating and subsequent cooling, which can cause the welded component to deform and distort. This distortion can adversely affect the dimensional accuracy and structural integrity of the weld joint. Through the application of controlled heat treatment, we can relieve the residual stresses induced during welding, reducing the distortion and ensuring the proper alignment and fit of the welded structure.

Prevents Stress Corrosion Cracking

Residual stresses in welded structures can significantly increase the susceptibility to stress corrosion cracking (SCC). SCC occurs when a corrosive environment, combined with tensile stresses, leads to crack initiation and propagation. Through post-weld heat treatment, we can effectively relieve these residual stresses, reducing the risk of stress corrosion cracking. By eliminating or minimizing the tensile stresses, the welded component becomes more resistant to corrosive environments, ensuring its long-term durability and structural integrity.

Enhances Fatigue Resistance

Fatigue failure is a common concern in welded structures, particularly in applications subjected to cyclic loading. Residual stresses from welding can significantly reduce the fatigue resistance of the welded component, making it more prone to fatigue cracking and failure. Post-weld heat treatment plays a vital role in relieving these residual stresses and improving the fatigue resistance of the weld joint. By subjecting the welded structure to controlled heating and cooling cycles, we can enhance its fatigue life, reducing the risk of premature failure and ensuring its reliable performance over time.

Reduces Hardness

Improves Machinability

In certain applications, the high hardness of a welded joint can pose challenges during machining operations. Post-weld heat treatment can be employed to reduce the hardness of the weld joint, making it more machinable. By subjecting the welded structure to specific heat treatment processes, we can transform the microstructure, reducing the hardness and improving the workability of the material. This allows for easier machining, resulting in more efficient and cost-effective manufacturing processes.

Minimizes Brittle Fracture

High hardness in welded structures can also increase the susceptibility to brittle fracture, especially in low-temperature environments or under high-stress conditions. Brittle fractures can occur without any significant deformation or warning signs, resulting in catastrophic failures. By implementing post-weld heat treatment, we can effectively reduce the hardness of the weld joint, making it less susceptible to brittle fracture. This improves the overall toughness and ductility of the welded component, ensuring its safe and reliable operation even in challenging conditions.

Increases Toughness

Toughness is a critical mechanical property for welded components, as it represents the material’s ability to withstand impact and absorb energy without fracturing. Welding can introduce microstructural changes that may adversely affect the toughness of the weld joint. Post-weld heat treatment helps optimize the microstructure, reducing the formation of brittle phases and enhancing the toughness of the welded material. This ensures that the weld joint can withstand sudden impact loads and provide adequate performance in demanding applications.

Enhances Corrosion Resistance

Stabilizes Alloys

Post-weld heat treatment is instrumental in stabilizing alloys and improving their corrosion resistance. During welding, the alloy’s microstructure undergoes significant changes, leading to the formation of less stable phases that are more prone to corrosion. By subjecting the welded structure to heat treatment, we can restore the alloy’s stability, promoting the formation of corrosion-resistant phases. This enhances the overall resistance of the welded component to various corrosion types, extending its service life and reducing the need for frequent repairs or replacements.

Improves Weld Overlay Performance

Weld overlays are commonly used in applications where enhanced corrosion resistance is required, such as in marine environments or chemical processing plants. The performance of these weld overlays depends significantly on the integrity of the overlay and its bond with the base material. Post-weld heat treatment plays a vital role in improving the bond strength and overall performance of weld overlays. By subjecting the weld overlay to controlled heating and cooling cycles, we can ensure proper fusion and metallurgical bonding, enhancing the corrosion resistance and durability of the overlay.

Prevents Intergranular Corrosion

Intergranular corrosion (IGC) is a common concern in welded structures, particularly in stainless steels and other corrosion-resistant alloys. IGC occurs along the grain boundaries, weakening the material and leading to premature failure. Post-weld heat treatment can effectively prevent intergranular corrosion by restoring the alloy’s microstructure and eliminating the sensitized grain boundaries. Through controlled heat treatment processes, we can ensure the removal of detrimental precipitates, minimizing the risk of IGC and enhancing the overall corrosion resistance of the welded material.

Prevents Delayed Cracking

Avoids Hydrogen-Assisted Cracking

Hydrogen-assisted cracking (HAC) is a severe form of delayed cracking that can occur in welded structures. During the welding process, hydrogen can become trapped in the weld metal, leading to the formation of hydrogen-induced cracks. Post-weld heat treatment is essential in preventing HAC by removing the trapped hydrogen and reducing the residual stresses in the weld joint. By subjecting the welded structure to controlled heating and cooling cycles, we can promote the redistribution and release of hydrogen, minimizing the risk of HAC and ensuring the structural integrity of the weld joint.

Avoids Embrittlement

Embrittlement is another form of delayed cracking that can affect welded structures. It occurs when certain alloys, such as carbon steels, become susceptible to brittle fracture due to exposure to specific environmental conditions or high temperatures. Post-weld heat treatment can help avoid embrittlement by promoting grain refinement and reducing the solute concentration in the alloy. Through controlled heat treatment, we can eliminate the conditions that lead to embrittlement, ensuring the ductility and toughness of the welded component under various operating conditions.

Minimizes Hot Cracking

Hot cracking, also known as solidification cracking, can occur during the solidification of the weld joint. It is characterized by crack formation in the weld metal or heat-affected zone due to high stress levels. Post-weld heat treatment can effectively minimize hot cracking by relieving the residual stresses in the weld joint and promoting better solidification behavior. By subjecting the welded structure to controlled thermal cycles, we can reduce the susceptibility to hot cracking, ensuring a defect-free weld joint and maintaining the structural integrity of the welded component.

Facilitates Weld Repairs

Removes Stress Concentration

When a weld joint becomes damaged or defective, repairs may be necessary to restore its structural integrity. Post-weld heat treatment can facilitate the repair process by removing stress concentration points. These stress concentration points occur at the edges of the repaired area, making the weld joint vulnerable to crack initiation and propagation. By subjecting the repaired weld joint to heat treatment, we can relieve these stress concentrations, redistributing the stresses and ensuring the weld’s long-term performance and integrity.

Restores Properties

During the repair process, the properties of the weld joint may be compromised due to the introduction of additional heat or the removal of material. Post-weld heat treatment plays a crucial role in restoring the properties of the repaired weld joint. By subjecting the repaired area to controlled heating and cooling cycles, we can refine the microstructure, relieve residual stresses, and optimize the material’s mechanical properties. This restores the weld joint to its original condition, ensuring that its performance meets the required standards and specifications.

Ensures Structural Integrity

The primary goal of weld repairs is to restore the structural integrity of the welded component. Post-weld heat treatment is essential in achieving this goal by ensuring the structural integrity of the repaired weld joint. Through controlled heat treatment, we can eliminate any defects or residual stresses introduced during the repair process. This allows for the reestablishment of the weld joint’s strength, ductility, and toughness, ensuring its reliable performance and longevity in the intended service conditions.

Improves Weld Quality

Reduces Inclusion Size

Inclusions, such as non-metallic elements or impurities, can affect the quality and integrity of a weld joint. Post-weld heat treatment can help improve weld quality by reducing the size and distribution of these inclusions. Through controlled heat treatment processes, we can promote the coalescence and dissolution of inclusions, resulting in a cleaner and more homogeneous microstructure. This enhances the weld joint’s mechanical properties, reduces the risk of defect formation, and ensures a higher quality and more reliable weld.

Enhances Fusion Zone Properties

The fusion zone, where the base material and the weld metal merge, is critical for the overall performance of a weld joint. Post-weld heat treatment can enhance the properties of the fusion zone by promoting desirable microstructural changes. Through controlled heating and cooling cycles, we can refine the fusion zone’s microstructure, ensuring adequate fusion and bonding between the base material and the weld metal. This improves the mechanical properties, such as strength and toughness, of the fusion zone, enhancing the overall quality and integrity of the weld joint.

Mitigates Weld Defects

Weld defects, such as porosity, lack of fusion, or cracking, can compromise the integrity and performance of a weld joint. Post-weld heat treatment can effectively mitigate these defects by promoting defect healing and enhancing the microstructural integrity of the weld joint. By subjecting the welded structure to controlled thermal cycles, we can promote the closure and healing of porosity or cracks, improving the overall integrity and strength of the weld joint. This reduces the risk of weld failure and ensures the long-term performance of the welded component.

Standard Compliance and Certification

Adherence to Industry Standards

Post-weld heat treatment is crucial for ensuring compliance with industry standards and specifications. Many industries, such as aerospace, automotive, and petrochemical, have specific requirements regarding weld quality, mechanical properties, and material performance. By following the recommended post-weld heat treatment procedures, we can ensure that the welded components meet these standards and comply with the industry’s regulatory requirements. This guarantees the consistent and reliable performance of the weld joint, ensuring its suitability for the intended application.

Quality Assurance and Compliance

Quality assurance is of utmost importance in welding operations, as it ensures the integrity and reliability of the welded components. Post-weld heat treatment plays a significant role in quality assurance by mitigating the risks associated with welding-induced defects and undesirable microstructural changes. Through proper heat treatment processes, we can minimize the potential for weld defects, relieve residual stresses, and optimize the material’s mechanical properties. This promotes compliance with quality standards, reduces the need for rework or component replacement, and ensures the overall quality and reliability of the weld joint.

Certification and Regulatory Requirements

In many industries, the certification and regulatory requirements for welded components are stringent and rigorous. Post-weld heat treatment is often a mandatory step to obtain the necessary certifications and approvals. By following the specified heat treatment procedures and documenting the process parameters, we can demonstrate compliance with the relevant certification and regulatory requirements. This allows for the validation and acceptance of the welded components in various industries, ensuring their safe and reliable operation.

Considerations and Best Practices

Suitability for Different Welding Processes

The suitability of post-weld heat treatment varies depending on the welding process used. Different welding processes, such as arc welding, resistance welding, or laser welding, have unique characteristics and requirements. It is essential to consider the specific heat treatment recommendations for each welding process to optimize the weld joint’s microstructure and properties. Understanding the interaction between the welding process and the heat treatment process is crucial in achieving the desired results and ensuring the weld’s quality and integrity.

Optimal Heat Treatment Techniques

The selection of optimal heat treatment techniques is imperative to achieve the desired microstructural changes and material properties. Factors such as the material type, thickness, and geometrical complexity of the welded component should be taken into account when determining the heat treatment regimen. Different techniques, such as annealing, tempering, or stress relieving, may be employed depending on the specific requirements and the material’s response to heat treatment. It is essential to consult relevant specifications, guidelines, and experts to determine the most suitable heat treatment technique for a given application.

Process Monitoring and Control

Proper process monitoring and control are critical during post-weld heat treatment to ensure consistent and reproducible results. Temperature, time, and cooling rates are among the key parameters that need to be closely monitored and controlled to achieve the desired microstructural changes and mechanical properties. Utilizing advanced heat treatment equipment and techniques, such as thermocouples or pyrometers for temperature measurement, can help ensure accurate and precise process control. Regular inspection and testing of the heat-treated components are also necessary to confirm the effectiveness of the heat treatment process and validate its compliance with the required specifications.

Economic and Safety Benefits

Cost Reduction in Material Replacement

Post-weld heat treatment can contribute to significant cost reduction by extending the lifespan of welded components. By optimizing the microstructure, relieving residual stresses, and enhancing the material’s mechanical properties, we can mitigate the risks associated with weld failures and premature component replacement. This reduces the overall maintenance and replacement costs, as the welded structures can operate reliably for a more extended period. Additionally, the improved performance and durability of the weld joint can minimize the need for expensive repairs or rework, further reducing the overall expenses.

Enhanced Product Performance and Lifespan

Post-weld heat treatment plays a crucial role in enhancing the performance and lifespan of welded components. By optimizing the microstructure and material properties, we can improve the structural integrity, fatigue resistance, and corrosion resistance of the weld joint. This ensures that the welded structures can withstand demanding operational conditions and provide reliable performance throughout their lifespan. The enhanced performance and extended lifespan of the welded components result in increased operational efficiency, reduced downtime, and improved customer satisfaction.

Mitigation of Safety Risks

Welded structures are often subjected to challenging operational conditions, such as high temperatures, intense pressures, or corrosive environments. Failure of these structures can pose significant safety risks to personnel and the environment. Post-weld heat treatment plays a vital role in mitigating these safety risks by ensuring the integrity and reliability of the weld joint. The reduction of residual stresses, optimization of material properties, and improvement of corrosion resistance contribute to the overall safety and risk reduction of the welded components. This promotes a safe working environment and prevents potential accidents or catastrophic failures.

In conclusion, post-weld heat treatment is of utmost importance in weld manufacturing processes. It ensures the optimal microstructure, controls grain growth and phase transformation, and improves the mechanical properties of the welded materials. It also relieves residual stresses, minimizes distortion, and enhances fatigue resistance. Post-weld heat treatment reduces hardness, improves machinability, minimizes brittle fracture, and increases toughness. Additionally, it enhances corrosion resistance, stabilizes alloys, improves weld overlay performance, and prevents intergranular corrosion. Post-weld heat treatment prevents delayed cracking and facilitates weld repairs while improving weld quality, reducing inclusion size, and mitigating weld defects. It ensures standard compliance and certification, adherence to industry standards, quality assurance and compliance, and meets regulatory requirements. Considerations and best practices include suitability for different welding processes, optimal heat treatment techniques, and process monitoring and control. Finally, it provides economic benefits by reducing costs in material replacement, enhancing product performance and lifespan, and mitigating safety risks.