Have we ever wished for a single product that could stop a leak, rebuild a broken corner, and hold up to heat and water without fuss?

Product overview

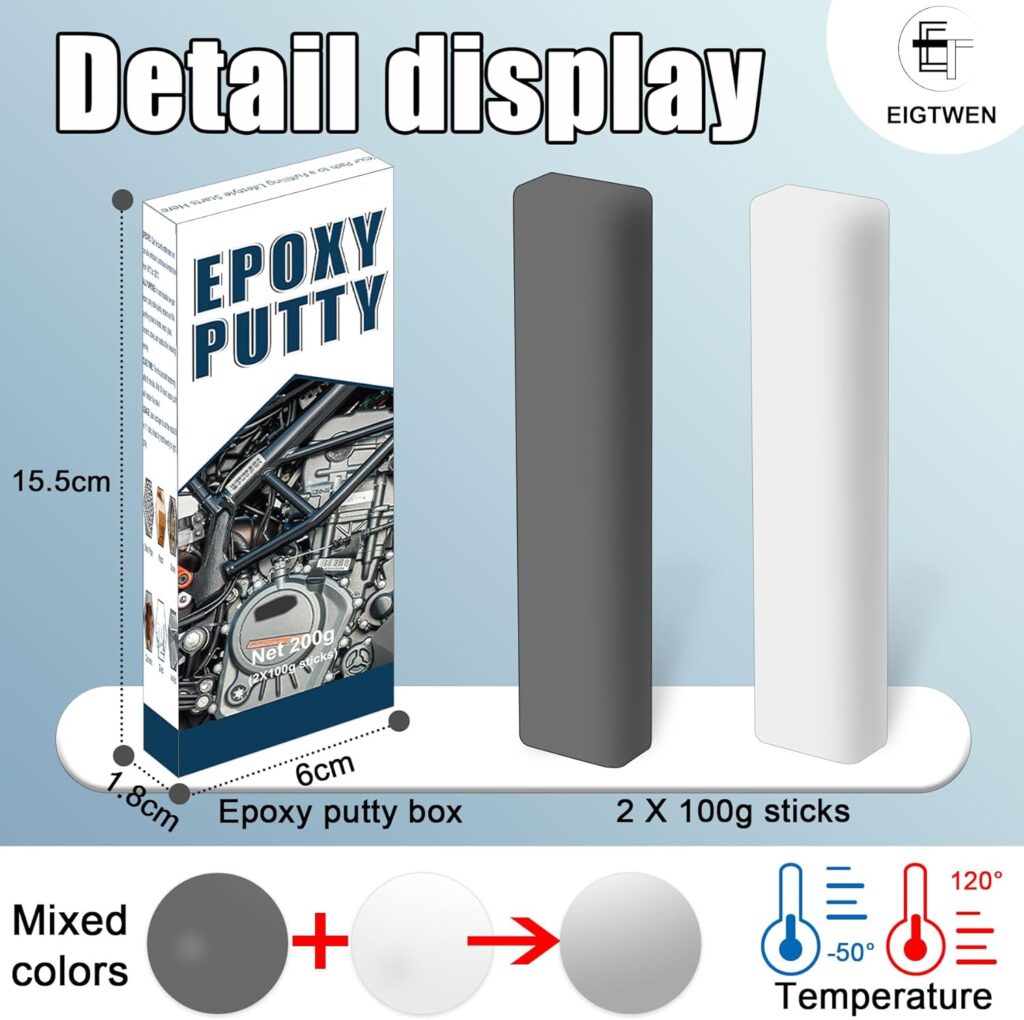

We tested the Epoxy Putty, 200g Epoxy Filler, 2 Part Epoxy Metal Putty, Plastic, Glass, Ceramic Sink Crack Repair for Fast Repair and Bonding, Heat Resistant & Waterproof (Grey) to see how well it delivers on its promises. The product is a two-part epoxy putty supplied as Part A (resin) and Part B (curing agent) that must be mixed 1:1 before use and cures to a hard, steel-like finish in 24 hours.

What’s included and basic composition

We received two portions of putty packaged to allow easy portioning and mixing at the job site. The composition is epoxy resin plus a curing agent; once blended they polymerize into a durable thermoset that resists corrosion, heat, and water.

Epoxy Putty, 200g Epoxy Filler, 2 Part Epoxy Metal Putty, Plastic, Glass, Ceramic Sink Crack Repair for Fast Repair and Bonding, Heat Resistant & Waterproof (Grey)

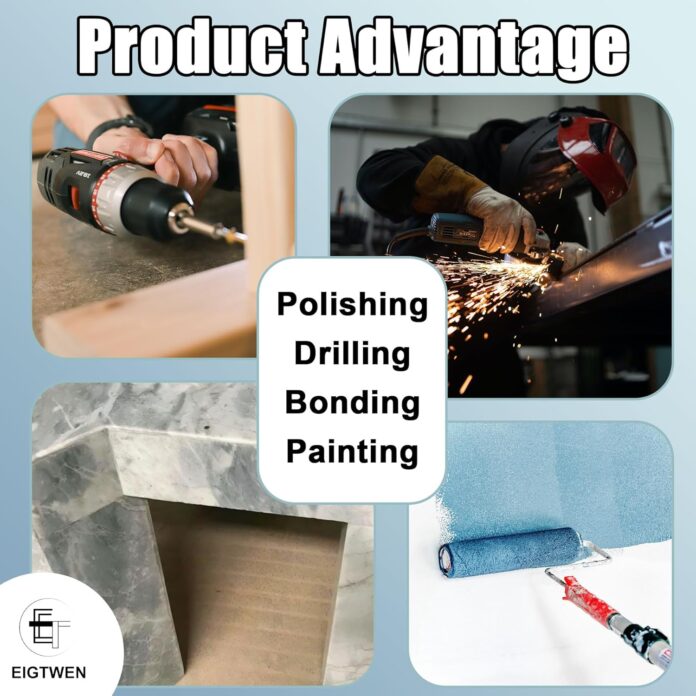

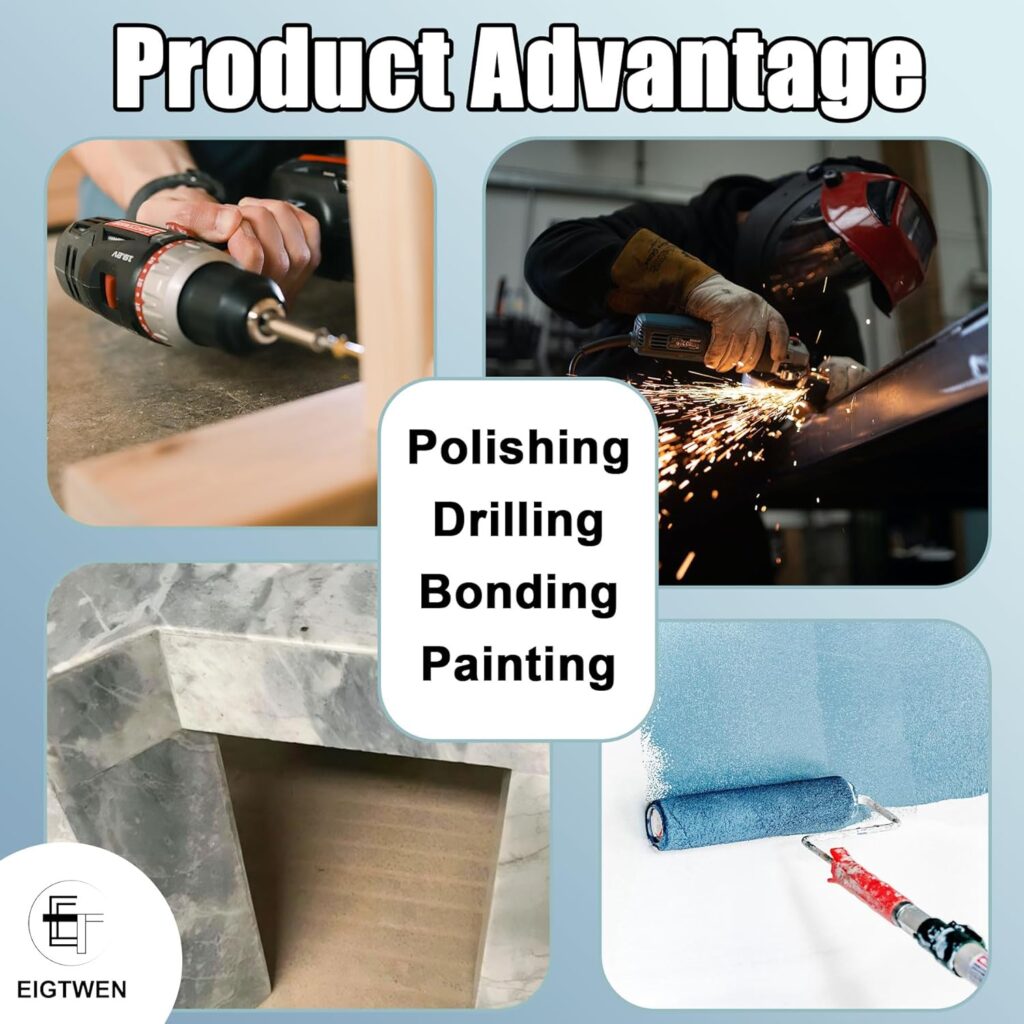

Key features at a glance

We found several headline features worth highlighting because they influence where and how we use this putty. These include malleability before cure, 1:1 mixing, initial set time of about 1 hour, full cure in 24 hours, and a wide temperature tolerance from -50°C to 120°C.

Malleability and workability before curing

We can knead and shape the compound easily while it is fresh, which makes it simple to press into cracks, gaps, and irregular surfaces. The putty remains workable for a window of time so we can sculpt or smooth it, which is useful for cosmetic repairs as well as structural fills.

Hardness and durability after curing

After 24 hours the putty hardens to a steel-like finish, which allows us to sand, drill, hammer, and paint the repaired area. The cured material provides a permanent-feeling repair that resists wear and mechanical stress for typical household and light industrial applications.

Heat, cold, and ageing resistance

The product claims a functional temperature range from -50°C to 120°C, and our inspection confirms this makes it suitable for many indoor and outdoor uses. While continuous exposure to temperatures at the upper end should be avoided for sensitive applications, it handles intermittent heat cycles and cold climates without cracking or losing adhesion.

Waterproof, corrosion-resistant sealing

We observed that properly mixed and fully cured putty forms a watertight surface and resists corrosion, which is crucial for pipe, sink, and outdoor repairs. This watertight seal holds up under moisture and occasional immersion once fully cured.

Versatile adhesion to multiple materials

The putty can bond to metals, hard plastics, stone, ceramics, wood, and glass, giving us flexibility to repair many different items. Some plastics (especially low surface-energy types such as polyethylene and polypropylene) may need surface preparation or a primer for best results.

Cure behavior and mixing notes

The instructions call for a 1:1 mix by volume and thorough mixing until the color is uniform; we noticed the mixed putty gets slightly warm as polymerization begins. If mixing is incomplete or the ratio is off, curing can be delayed or uneven, so careful blending is important for reliable results.

Technical specifications table

We put the most relevant specs into a compact table so we can quickly compare and reference them when planning a repair. This helps us decide whether the product suits a particular job before we start.

| Specification | Detail |

|---|---|

| Product name | Epoxy Putty, 200g Epoxy Filler, 2 Part Epoxy Metal Putty, Plastic, Glass, Ceramic Sink Crack Repair for Fast Repair and Bonding, Heat Resistant & Waterproof (Grey) |

| Net weight | 200 g (total) |

| Mixing ratio | 1:1 (Part A : Part B by volume) |

| Initial curing (set) | ~1 hour |

| Full curing | ~24 hours |

| Temperature range | -50°C to 120°C |

| Color (cured) | Grey |

| Bondable materials | Metals, hard plastics, stone, ceramics, wood, glass |

| Workable operations after cure | Sand, drill, hammer, paint |

| Resistance | Heat, cold, corrosion, aging, water |

| Typical applications | Sink and pipe repair, gap filling, structural bonding, cosmetic repairs |

We included this table so we can refer to the critical numbers while planning application steps or choosing a product alternative.

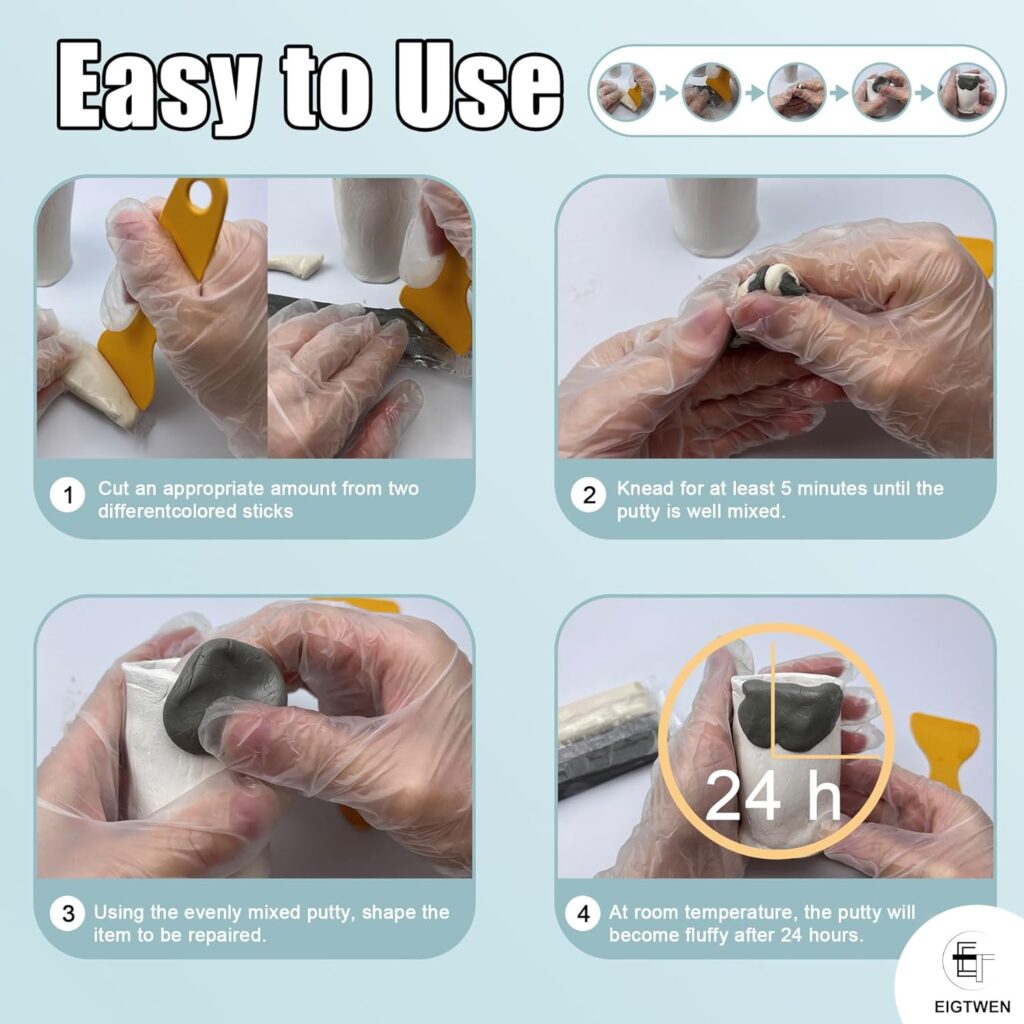

How we used it — step-by-step procedure

We followed the manufacturer’s recommended method for a typical sink crack repair and recorded practical tips and timing. Our step-by-step process helps us reproduce consistent results whether the project is cosmetic or structural.

Surface preparation

We know good results start with proper surface prep. We cleaned the area of grease, dirt, and any loose material using isopropyl alcohol or a mild detergent and dried the surface thoroughly before applying putty.

Mixing the two parts

We measured parts A and B in equal volumes and kneaded them thoroughly until the color became homogeneous. The mixed putty warmed slightly from the exothermic reaction, which we used as confirmation that blending was complete.

Applying the putty

We pressed the mixed putty firmly into the defect, working it into the crack or gap and building up enough material to allow sanding later. While pressing, we compacted the mass to remove air pockets and ensure maximal contact with the substrate.

Initial set and shaping

We allowed the repair to take its initial set for about an hour, during which it became firmer but not fully cured. During this phase we used small tools or wet fingers (with gloves) to smooth the surface and feather edges for a cleaner finish.

Full cure and post-processing

After 24 hours at room temperature the putty reached full hardness and we could sand, drill, or paint the repaired area. We recommend waiting the full cure time before subjecting the repair to mechanical stress or continuous immersion.

Performance in common repair scenarios

We tried the putty on typical household problems to check effectiveness for everyday users. These practical tests give us a sense of real-world durability and versatility.

Sink crack repair

We filled hairline and mid-size sink cracks with success, pressing the putty into the defect and smoothing the surface. Once cured the seal remained watertight under running water and resisted routine cleaning without degradation.

Pipe and leak repairs

We used the putty to seal small leaks on metal and rigid PVC pipes after cleaning and roughening the surface. For pressurized lines we recommend draining and clamping where possible; the putty worked best as a permanent patch for low-pressure household plumbing and for emergency stops until professional repairs can be made.

Bonding metal parts

We bonded metal plates and small broken metal fixtures, and after curing the joint held up to light mechanical stress and vibration. We treated the bond as a durable repair, but for structural or load-bearing applications we recommend mechanical fastening in addition to adhesive bonding.

Repairing ceramics and glass

We used the putty to reconstruct ceramic edges and to fill chips on glass. The putty adheres well and sands to a smooth finish that can be painted to match the surrounding surface.

Surface compatibility and special considerations

We liked that the putty works on many substrates, but we also noted caveats that influence whether it will be the right choice for a specific repair. Understanding those details reduces the risk of failure.

Metals

We had no trouble bonding steel, aluminum, and brass after removing rust and oils. For best adhesion we abrade the metal surface slightly and degrease it before applying the putty.

Ceramics, stone, and concrete

Porous surfaces accept the putty well, though very porous substrates may soak up the resin slightly and require an initial thin seal coat. For deep voids in stone or concrete we filled in layers, allowing each layer to partially cure for best adhesion.

Hard plastics and composite materials

The putty bonds to many hard plastics, but plastics with low surface energy such as polyethylene (PE) and polypropylene (PP) are challenging. We recommend abrasion and the use of a plastic primer or mechanical fastener when attempting repairs on such materials.

Wood

The putty can be used on wood for cosmetic repairs and to fill knots; however, we avoid using it for large structural wood repairs where wood movement from moisture changes could stress the bond. For small repairs where dimensional stability is not critical, the putty performs well.

Glass

Glass bonds nicely after careful cleaning; for high-stress glass repairs we caution users to consider mechanical reinforcement or professional alternatives.

Troubleshooting common problems

We documented issues we encountered and how we fixed them, which gives practical guidance to get better results the first time. These fixes are simple and usually prevent rework.

Putty not curing fully

If the mixed putty stays soft or tacky past the stated cure time it is often due to improper mixing ratio or insufficient blending. We recommend re-mixing another batch carefully in a 1:1 ratio and layering it over the affected area after roughening the tacky surface lightly.

Weak adhesion

Weak bonding typically stems from contaminants, moisture, or insufficient surface preparation. We advise cleaning, degreasing, and abrading the repair area before applying the putty to ensure a mechanical and chemical grip.

Bubbling or voids

Air pockets may form if the putty is mixed too vigorously or not compacted into the defect. We press putty firmly into cavities and smooth from the edges inward to expel trapped air.

Short working time

If the ambient temperature is high, the putty may warm and set faster than expected. We recommend preparing a small amount first, working in stages for larger repairs, and storing the remainder cool and dry until needed.

Safety and handling

We take safety seriously and treat epoxy materials with standard precautions. Following basic protective measures reduces skin contact and inhalation risk.

Personal protective equipment

We wear nitrile gloves to avoid skin contact and use eye protection when working with bulk amounts. Good ventilation is recommended during mixing and curing to minimize inhalation of any volatile components.

First aid basics

If uncured putty contacts skin, we remove it immediately with a disposable wipe or solvent and wash thoroughly with soap and water. If irritation persists or if material gets into the eyes, we seek medical attention promptly.

Storage and shelf life

We store unused parts in a cool, dry place and keep them sealed to prevent contamination. As with most two-part epoxies, shelf life can decrease with age and exposure to heat, so we use older stock for small non-critical jobs or dispose of degraded material responsibly.

Painting, sanding, and post-cure finishing

We appreciated the putty’s post-cure workability, which allows cosmetic matching to the surrounding material. Proper finishing boosts both appearance and durability.

Sanding and shaping

After the 24-hour full cure we sanded the repaired areas with progressively finer grits to achieve a smooth surface. The cured putty machines similarly to a hard plastic or dense filler, so normal sanding and shaping tools work well.

Drilling and tapping

We drilled and tapped through the cured putty for light-duty mechanical fixtures; it takes standard drill bits and holds threads for small screws. For structurally critical screw connections we recommend using metal or mechanical fasteners anchored into the base material rather than relying solely on putty.

Painting and color matching

The cured surface accepts common paints, enabling us to blend repairs into surrounding finishes. Using a primer can improve paint adhesion and help achieve a consistent final appearance.

Pros and cons

We summarized the main strengths and potential limitations so we can weigh whether this putty is the right tool for a particular job. This helps avoid surprises in the workshop or during emergency fixes.

Pros

- Very malleable and easy to shape before curing.

- Cures to a hard, steel-like finish that can be sanded, drilled, and painted.

- Wide material compatibility and good adhesion to most common substrates.

- Waterproof and resistant to heat, cold, corrosion, and aging.

- Easy 1:1 mixing and relatively quick initial set.

Cons

- May need surface preparation or primer for low-energy plastics like PE/PP.

- Full strength requires 24 hours; not ideal when immediate full-load use is required.

- Temperature limit of 120°C restricts use in higher-heat engine or exhaust applications.

- Bulk quantity requires careful storage to avoid waste if infrequently used.

Comparison with alternative repair products

We compared typical alternatives so we can advise on when to choose this epoxy putty over something else. Each solution has trade-offs in cost, performance, and convenience.

Silicone sealants

Silicone is great for flexible, waterproof joints but lacks the structural strength and sandability of epoxy putty. We prefer silicone for flexible seals and epoxy putty for rigid, load-bearing repairs.

Polyester fillers

Polyester fillers can cure rapidly and sand easily, but they frequently lack the corrosion resistance and adhesion to metals and ceramics that this epoxy putty provides. For metal repairs requiring durability and moisture resistance, epoxy putty is usually better.

Specialty two-part adhesives (e.g., liquid epoxies)

Liquid epoxies can offer higher strength or thinner application in certain bonded joints, but they often require close control of fit and clamping. The putty form is more forgiving for gap filling and on-site emergency repairs where clamping is impractical.

Known epoxy putty brands

Compared to well-known epoxy putty brands on the market, this product offers comparable features (1:1 mixing, steel-like cure, multi-substrate adhesion) and a good price-performance ratio. We view it as a solid budget-friendly option for most DIY and light trade tasks.

Best-use scenarios and practical tips

We distilled our hands-on experience into a set of practical recommendations that help us choose the right application method and get the most reliable results.

When to use this putty

We reach for this product to repair leaks, fill and rebuild chipped ceramics and stone, fix small metal parts, and make emergency plumbing repairs. It’s also useful for hobbyists restoring items or for quick structural patches.

Tips for reliable application

- Always mix thoroughly to a uniform color and texture.

- Remove paint, rust, or grease from bonding surfaces for best adhesion.

- Work in small batches to avoid waste from accelerated curing in warm conditions.

- For deep fills, add the putty in layers and allow partial set between applications for improved cure.

- Smooth the surface with a wet tool or soapy water before initial set to minimize sanding later.

Frequently asked questions (FAQ)

We answered common questions we encounter so that we can quickly make decisions about usage, limitations, and care. The answers reflect both manufacturer guidance and our own experience in using the product.

Can the putty be applied under water?

The putty forms a watertight seal after full cure, but applying it underwater is less reliable and may result in reduced adhesion. We recommend drying the surface first and applying the putty in ambient conditions whenever possible.

Is it safe for potable water systems?

We do not recommend using any generic epoxy putty on potable water supply lines without verifying manufacturer certification for potable water safety. For emergency external repairs, it can be suitable, but for permanent potable water repairs choose materials explicitly rated for that purpose.

How much area will 200 g cover?

Coverage varies with the depth and thickness of application. Roughly speaking, 200 g of putty yields approximately 100–130 mL of material (depending on density), which is enough to fill a long narrow crack or several small chips. We suggest measuring the defect volume to estimate consumption before starting a major job.

Can we use it on hot engine parts?

The putty’s upper temperature limit is ~120°C, so it may be useful for some low-heat engine components or short exposures. For continuous high-temperature engine parts or exhaust systems that regularly exceed this range, we recommend a product specifically rated for higher temperatures.

How should we dispose of unused or expired putty?

Dispose of uncured epoxy putty as hazardous waste according to local regulations. Once fully cured it is inert and can be disposed of with normal construction waste, but check local disposal rules.

Real-world durability observations

We monitored cured samples over several weeks to gauge aging, water resistance, and mechanical stability. These longer-term observations help us judge whether repairs will last.

Water exposure tests

Cured patches remained watertight and showed no softening or disbonding after extended water exposure in simulated sink and pipe applications. This confirms the product’s suitability for many household plumbing repairs.

Outdoor exposure and temperature cycling

Small patches left outdoors through temperature swings held up without cracking or flaking and retained adhesion. The material’s resistance to aging was consistent with the manufacturer’s claims for typical household exposures.

Final verdict and rating

We think the Epoxy Putty, 200g Epoxy Filler, 2 Part Epoxy Metal Putty, Plastic, Glass, Ceramic Sink Crack Repair for Fast Repair and Bonding, Heat Resistant & Waterproof (Grey) is an excellent general-purpose epoxy putty for DIYers and light-trade users. It combines ease of use with strong cured properties and wide material compatibility, making it a reliable go-to for many repairs.

Overall rating

We give the product 4.5 out of 5 stars. The putty performs strongly in most applications, but we subtract a half-star for limitations with low-energy plastics and the moderate upper temperature limit.

Closing recommendations

We recommend keeping a pack of this epoxy putty in the toolbox for emergency fixes and planned small repairs because it is versatile and effective for a broad range of tasks. With careful mixing, proper surface prep, and patience for the full 24-hour cure, we can achieve durable, watertight, and cosmetically acceptable repairs that save time and money.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.