In the world of welding, there are two main players: manual welding and robotic welding tools. While both techniques aim to achieve the same end result, they have distinct differences in terms of operation, efficiency, and precision. Manual welding, often performed by skilled human welders, requires hands-on control and expertise, offering flexibility and adaptability in various welding tasks. On the other hand, robotic welding tools utilize advanced technology and automation to enhance productivity, consistency, and accuracy. This article explores the contrasts between these two methods and highlights the unique benefits they bring to the world of welding.

This image is property of alsafriksteel.com.

Speed and Productivity

Manual Welding

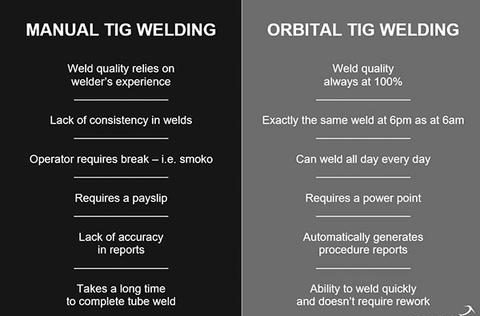

When it comes to speed and productivity, manual welding has its limitations. Since it relies solely on the skill and experience of the welder, the speed at which the welding can be done is limited. The welder has to manually control the welding torch and make adjustments as necessary, which can slow down the process. Additionally, manual welding requires breaks for the welder to rest and recover, further reducing the overall productivity.

Robotic Welding

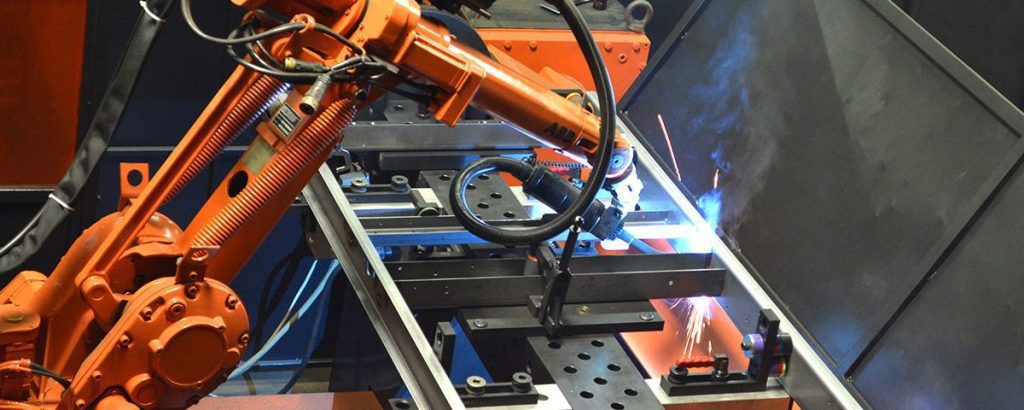

On the other hand, robotic welding is known for its speed and efficiency. With robotic welding, the welding process is automated, and the robot can work at a constant speed without any breaks. This can significantly increase the productivity as robots can work non-stop for extended periods of time. Moreover, robotic welding machines are designed to perform repetitive tasks with precision, allowing for faster completion of welding projects.

Accuracy and Consistency

Manual Welding

Manual welding can be prone to human errors, which can affect the accuracy and consistency of the welds. The welder’s skill and experience play a crucial role in achieving accurate and consistent welds. However, factors such as fatigue, distractions, and variations in technique can lead to inconsistencies and imperfections in the welds. Achieving precise and identical welds throughout a project can be challenging with manual welding.

Robotic Welding

Robotic welding offers a higher level of accuracy and consistency compared to manual welding. The welding process is controlled by computer programs that ensure precise and repeatable welds. Robots are not susceptible to human errors and do not get tired, resulting in consistently high-quality welds. Additionally, the use of sensors and advanced technology allows the robot to adapt to changes in the environment and make real-time adjustments, further enhancing accuracy.

Labor and Skill Requirements

Manual Welding

Manual welding requires skilled welders who have undergone extensive training and have years of experience. It takes time and effort to become proficient in manual welding techniques and to develop the necessary hand-eye coordination. In addition, manual welding often requires the presence of multiple welders for larger projects, which increases labor requirements.

Robotic Welding

Robotic welding reduces the labor and skill requirements as it eliminates the need for human welders. The operation and programming of robotic welding machines require a different set of skills that can be acquired through specific training or education. Once programmed, the robots can work autonomously, reducing the need for human intervention. This not only reduces labor costs but also frees up skilled welders to focus on more intricate tasks.

Safety

Manual Welding

Safety is a critical consideration in manual welding. Welders are exposed to various hazards, such as flying sparks, intense heat, toxic fumes, and potential eye damage. Protective gear, including helmets, gloves, and welding aprons, must be worn to minimize the risk of injuries. The welder must also ensure proper ventilation and take precautions to prevent accidents, such as fire or electrical hazards.

Robotic Welding

Robotic welding offers improved safety compared to manual welding. Since the welding process is automated, there is minimal direct human contact with the welding operation. This reduces the risk of physical injuries from sparks and heat exposure. Robots are also equipped with safety features, such as sensors that can detect the presence of humans and automatically shut down or slow down the operation to avoid accidents. However, proper safety protocols and precautions must still be followed when working with robotic welding machines.

This image is property of www.zzkehui.com.

Cost

Initial Investment

The cost of implementing manual welding or robotic welding tools can vary significantly, depending on various factors. In terms of the initial investment, manual welding tends to be less expensive. Manual welding tools, such as welding torches, gas cylinders, and protective gear, are relatively affordable and readily available. However, the cost can increase if additional equipment or specialized tools are required for specific projects.

Robotic welding, on the other hand, requires a significant initial investment. The cost of purchasing and installing robotic welding machines, programming software, and safety measures can be substantial. Additionally, specialized training or hiring experts to program and operate the robots may be necessary, adding to the overall cost.

Maintenance and Operating Costs

Manual welding tools generally have lower maintenance costs. Regular maintenance and occasional replacement of consumables, such as welding electrodes, gas nozzles, and contact tips, are the primary costs associated with manual welding. However, the operating costs, including labor and energy costs, can add up over time.

Robotic welding machines require regular maintenance to ensure proper functioning and longevity. This may involve scheduled inspections, calibrations, and lubrication of the robotic system. The cost of maintenance and repairs can be higher compared to manual welding. However, once installed, robotic welding machines usually have lower operating costs as they require minimal human intervention and can operate continuously, reducing labor expenses.

Versatility

Manual Welding

Manual welding is known for its versatility. Welders can adapt their techniques and equipment to a wide range of welding applications, materials, and shapes. They can adjust the angle, speed, and distance of the welding torch to meet specific project requirements. Manual welding allows for precise control, making it suitable for intricate and detailed welds.

Robotic Welding

Robotic welding, although highly efficient, lacks the flexibility and versatility of manual welding. The robot’s movements and welding parameters are predetermined by the programmed instructions, limiting the ability to adapt to varying project requirements. While robotic welding can still handle a wide range of welding tasks, it may not be suitable for highly complex or non-standard welding applications that require precise human control.

This image is property of metalexponents.com.

Complexity of Welds

Manual Welding

Manual welding provides greater control and is better suited for handling complex welds. Skilled welders can make adjustments on the fly and adapt their technique to achieve optimal results. Manual welders can manipulate the welding torch to navigate intricate joints or hard-to-reach areas. This level of control allows for the successful completion of complex welds that may require precise positioning and manipulation.

Robotic Welding

Robotic welding machines are generally better suited for handling simple and repetitive welding tasks. While they can perform basic welds with precision and speed, the complexity of welds that require intricate adjustments or non-linear paths may pose a challenge. The predefined movements and limitations of the robotic arm may limit its ability to execute highly complex welds. Advanced robotic systems with advanced kinematics and sensors can handle more complex welds, but they come at a higher cost.

Adaptability to Changing Work Conditions

Manual Welding

Manual welding is highly adaptable to changing work conditions. Welders can make on-the-spot adjustments to their techniques or equipment to accommodate variations in the work environment, materials, or project requirements. They can quickly change welding parameters, such as voltage, current, or wire speed, to achieve the desired results. Manual welders can also troubleshoot and address any unexpected challenges or issues that may arise during the welding process.

Robotic Welding

Robotic welding, while less adaptable than manual welding, can still handle certain changes in work conditions. Robots equipped with sensors and advanced programming can detect variations in joint position or material thickness and make necessary adjustments to maintain quality welds. However, major changes or unforeseen circumstances may require reprogramming or human intervention, which can lead to downtime and decreased productivity.

This image is property of www.genesis-systems.com.

Human Factors

Manual Welding

Manual welding relies heavily on the skill, experience, and decision-making abilities of human welders. Skilled welders can make real-time assessments and adjustments based on visual and tactile feedback, ensuring optimal weld quality. The manual welding process also allows for direct communication and collaboration between welders, supervisors, and project teams, fostering a sense of teamwork and cooperation.

Robotic Welding

Robotic welding removes the human interaction from the welding process, which can have both advantages and disadvantages. While it eliminates the potential for human errors and injuries, it also removes the expertise and judgment that skilled welders bring to the table. Robots lack the ability to make subjective decisions or adapt to unique situations. However, humans are still essential in programming, maintaining, and overseeing the robotic welding operations.

Quality Control

Manual Welding

Quality control in manual welding heavily relies on the skill and experience of the welder. Skilled welders can visually inspect the welds, assess their integrity, and make any necessary repairs or adjustments. However, human error, fatigue, or distractions can result in inconsistencies or defects in the welds. Real-time quality control measures can be implemented, such as X-ray or ultrasonic inspections, but these can be time-consuming and costly.

Robotic Welding

Robotic welding offers consistent and reliable quality control. The automated process ensures that welding parameters and techniques are consistently carried out, minimizing the risk of defects. Robotic systems can be equipped with internal quality control measures, such as sensors and cameras, to monitor and verify the weld quality in real-time. This allows for instant identification of any issues or deviations from the desired specifications, improving overall quality control.

In conclusion, the differences between manual welding and robotic welding tools are significant and depend on the specific requirements of the welding project. Manual welding offers versatility, adaptability, and the ability to handle complex welds, but it is limited by the speed and productivity of the welder, the potential for human errors, and higher labor requirements. Robotic welding, on the other hand, offers increased speed, productivity, accuracy, and consistency. It reduces labor and skill requirements, provides improved safety, and allows for better quality control. However, robotic welding may lack the adaptability and flexibility of manual welding, especially in complex or non-standard welding applications. Ultimately, the choice between manual and robotic welding depends on factors such as project complexity, volume, budget, and desired level of control.

This image is property of www.macmetal.com.