Are you unsure about which welding process to choose for your upcoming project?

With so many options available, it can be overwhelming to make the right decision.

Don’t worry, though! In this article, we will guide you through the factors to consider when selecting a welding process.

By the end, you’ll have a clear understanding of which method is best suited to your specific project needs.

Factors to Consider

When deciding which welding process to use for your project, there are several important factors to consider. These factors will help guide you in choosing the most appropriate welding method for your specific needs. Let’s take a closer look at each factor and how it can impact your decision.

Material

The type of material you are working with is a crucial consideration when selecting a welding process. Different materials have different properties and react differently to heat and pressure.

For example, if you are working with steel, you may opt for a different welding process compared to working with aluminum or stainless steel. It’s important to understand the specific material you are working with and choose a welding process that is compatible with it.

Thickness

The thickness of the material also plays a role in determining the appropriate welding process. Some welding methods are better suited for thinner materials, while others are more effective for thicker materials.

It’s essential to consider the thickness of the material you are working with to ensure that the welding process you choose can provide adequate penetration and strength.

Joint Type

The type of joint you need to create is another critical factor in selecting a welding process. Different welding methods excel at specific joint types, such as butt joints, lap joints, or T-joints. Understanding the joint type you need to create will help narrow down the welding processes that are suitable for your project.

Welding Position

The welding position refers to the orientation in which the welding is performed, such as flat, horizontal, vertical, or overhead. Not all welding processes are suitable for all positions.

Some welding methods, like flux-cored arc welding, may be better suited for overhead or vertical positions, while others, like gas tungsten arc welding, may be more convenient for flat or horizontal positions. Considering the welding position is crucial to ensure that the welding process you choose can effectively handle the position requirements of your project.

Skill Level

Your own skill level and experience with different welding processes should also be taken into account. Some welding methods, like shielded metal arc welding (SMAW) or oxy-fuel welding, may be more forgiving for beginners and less experienced welders. On the other hand, processes like gas tungsten arc welding (GTAW) or laser welding require more advanced knowledge and skill. It’s important to assess your own welding abilities and select a process that matches your skill level to ensure quality and safety.

Arc Welding Processes

Arc welding is a widely used welding process that utilizes an electric arc to create a weld. There are several types of arc welding processes, each with its own advantages and applications.

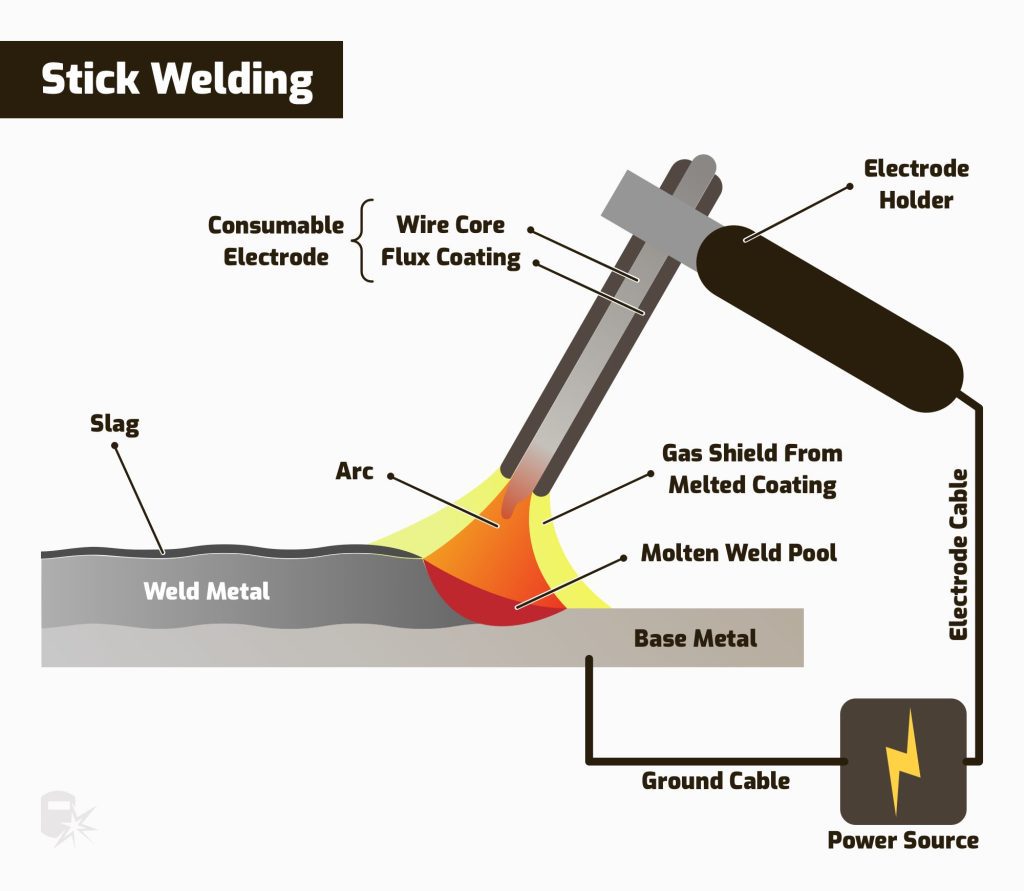

Shielded Metal Arc Welding (SMAW)

Shielded Metal Arc Welding, also known as stick welding, is one of the oldest and most straightforward forms of arc welding. It involves using a consumable electrode coated with a flux to generate an arc between the electrode and the workpiece. The flux creates a shielding gas that protects the weld pool from atmospheric contamination.

SMAW is versatile and can be used for welding various materials and joint types. It is often favored for its portability and ability to withstand adverse conditions. However, SMAW may be slower compared to other arc welding processes and requires more post-weld cleanup.

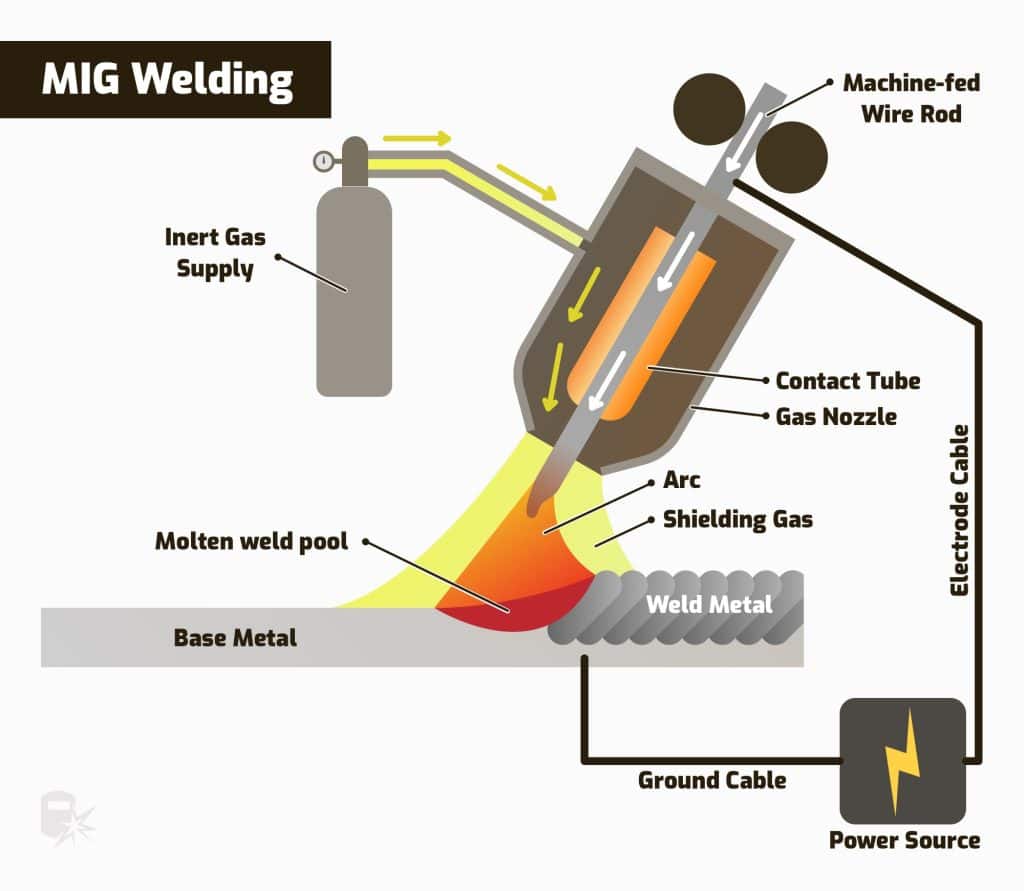

Gas Metal Arc Welding (GMAW)

Gas Metal Arc Welding, also known as MIG (Metal Inert Gas) welding, is a popular arc welding process that utilizes a wire electrode and a shielding gas to form the weld.

The wire electrode continuously feeds from a spool, and an arc is created between the wire and the workpiece. The shielding gas protects the molten weld pool from atmospheric contamination.

GMAW is known for its versatility, high welding speed, and ability to weld a wide range of materials. It is commonly used in automotive, manufacturing, and construction industries. However, GMAW may require significant equipment setup and may not be suitable for outdoor welding due to wind interference.

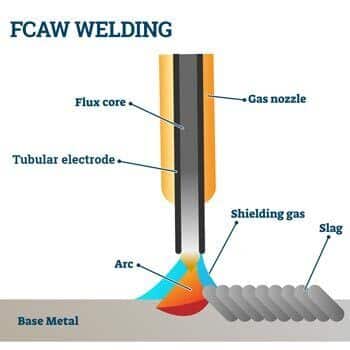

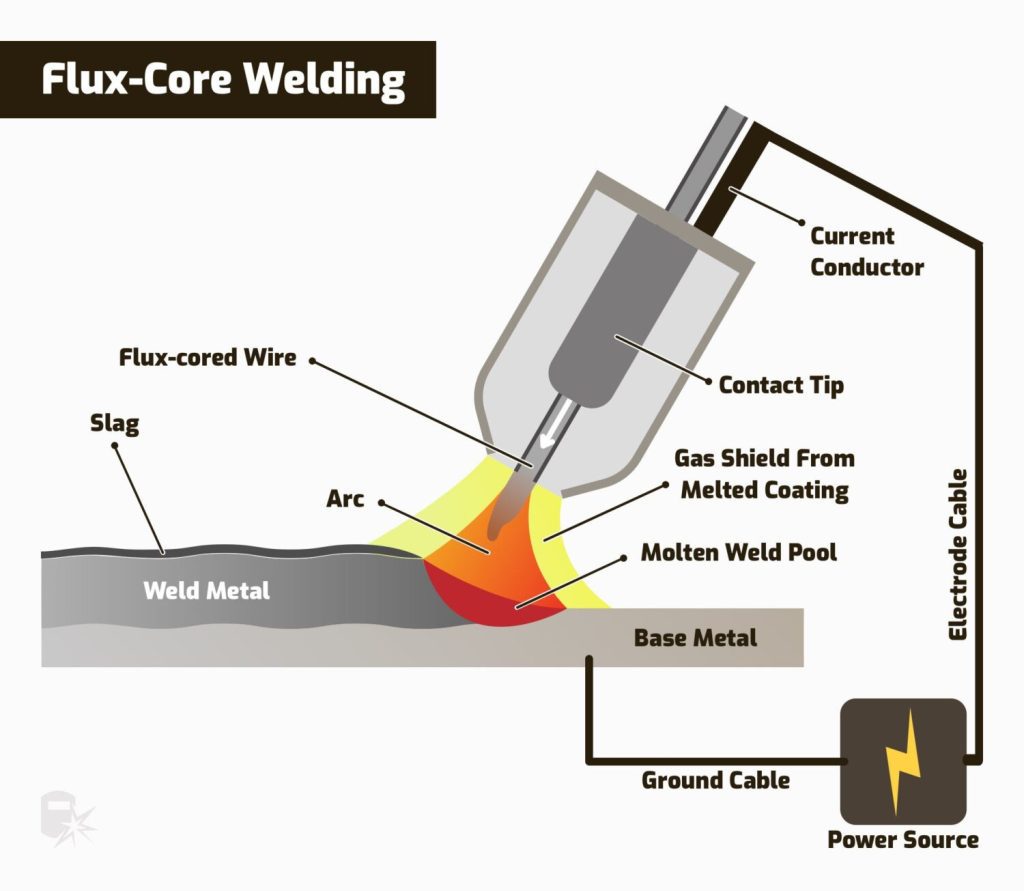

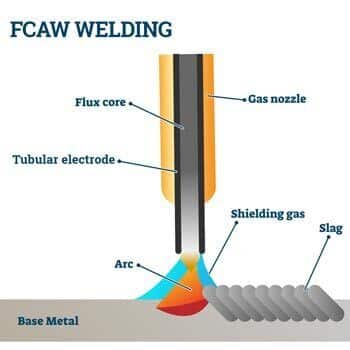

Flux-Cored Arc Welding (FCAW)

Flux-Cored Arc Welding is a variation of GMAW that uses a tubular wire electrode filled with flux instead of a solid wire.

The flux serves both as a shielding agent and a source of additional alloying elements. FCAW is often favored for its high welding speed, deep penetration, and suitability for outdoor welding due to its self-shielding capabilities.

It can be used on thick materials and in various welding positions. However, FCAW may produce more spatter compared to other arc welding processes, and the flux may need to be cleaned after welding.

Gas Tungsten Arc Welding (GTAW)

Gas Tungsten Arc Welding, also known as TIG (Tungsten Inert Gas) welding, is a precise and versatile arc welding process.

It utilizes a non-consumable tungsten electrode and a shielding gas to produce the weld. The weld pool is protected from atmospheric contamination by the shielding gas, while the tungsten electrode provides the arc.

GTAW is known for its ability to produce high-quality and aesthetically pleasing welds on a variety of materials, including aluminum, stainless steel, and titanium. It offers excellent control, low heat input, and minimal spatter.

However, GTAW requires advanced welding skills and may be slower compared to other arc welding processes.

Resistance Welding Processes

Resistance welding is a group of welding processes that generate heat by passing a current through the parts being joined. The heat generated by resistance welding allows for the fusion of the materials. The following are some common resistance welding processes:

Spot Welding

Spot welding is one of the most common resistance welding processes. It involves applying current to two metal sheets held together under pressure. The heat generated at the contact point causes the metal sheets to melt and form a weld nugget.

Spot welding is widely used in industries like automotive manufacturing, where it is used to join sheet metal components. It is known for its high productivity and efficiency. However, spot welding is limited to joining thin materials and may not be suitable for thicker or dissimilar materials.

Projection Welding

Projection welding is similar to spot welding but involves using specially designed projections on the metal sheets to concentrate the heat and form the weld. The projections serve as small electrodes that focus the current flow and heat.

Projection welding is commonly used for joining components with irregular geometries or thick materials. It provides strong and reliable welds while allowing for efficient production. However, the need for projections on the workpieces may add complexity to the joint design.

Seam Welding

Seam welding is a continuous resistance welding process used to create a leak-proof joint along the length of two or more overlapping metal sheets. It involves passing a current through the sheets and applying pressure as they move along a welding wheel or roller.

Seam welding is commonly used in the production of cylindrical or tubular components, such as fuel tanks or pipes. It offers high-speed welding and ensures consistent and watertight joints. However, seam welding may require specialized equipment and may not be suitable for all joint configurations.

Flash Welding

Flash welding is a resistance welding process that utilizes the heat generated by a controlled electrical discharge. The workpieces are clamped together, and a high electrical current is passed through them.

The resulting heat causes the ends of the workpieces to melt and fuse together. Flash welding is commonly used for joining large or complex-shaped parts, such as shafts or pipes. It provides strong and reliable welds, often with minimal material distortion. However, flash welding requires precise control and may not be suitable for all material combinations.

Other Welding Processes

In addition to arc welding and resistance welding processes, there are several other welding methods available for specific applications. These processes offer unique advantages and may be suitable for specialized projects.

Oxy-Fuel Welding

Oxy-Fuel Welding, also known as gas welding, is a process that uses a flame produced by mixing fuel gas (such as acetylene) with oxygen. The heat from the flame melts the edges of the workpieces, and a filler metal is added to create the weld.

Oxy-Fuel Welding is commonly used for repairs, heating, and cutting operations. It offers portability and simplicity but may not provide the same level of precision and control as other welding processes. It is often favored for its versatility and ability to work with a wide range of materials.

Plasma Arc Welding

Plasma Arc Welding (PAW) is an advanced welding process that uses a high-velocity plasma arc to create the weld. The plasma is formed by ionizing gas passing through a nozzle and an electric arc is generated within the plasma stream.

PAW offers high input energy, concentrated heat, and superior control. It is commonly used for precision welding of thin materials, such as in the aerospace or electronics industries. PAW provides excellent weld quality, low distortion, and minimal heat-affected zone. However, it requires specialized equipment and may have higher initial costs.

Electron Beam Welding

Electron Beam Welding (EBW) is a high-energy welding process that uses a focused beam of high-velocity electrons to melt and fuse the workpieces. EBW offers deep penetration, excellent control, and minimal heat-affected zone.

It is commonly used for welding materials with high melting points, such as refractory metals or certain alloys. EBW provides high-quality welds with little to no distortion or residual stress. However, it requires vacuum chambers and specialized equipment, making it a more complex and expensive process.

Laser Welding

Laser Welding utilizes a highly concentrated laser beam to melt and fuse the workpieces. The laser beam provides precision and control, allowing for high-quality welds with minimal heat input.

Laser Welding is commonly used for welding small or delicate components, such as in the medical or jewelry industries. It offers fast welding speeds, narrow heat-affected zones, and can be used on a variety of materials. However, laser Welding may have high initial costs and requires careful consideration of safety precautions due to the powerful laser beam.

Pros and Cons of Each Process

Now that we have explored the various welding processes, let’s discuss their pros and cons to help you make an informed decision.

Shielded Metal Arc Welding (SMAW)

- Pros: Portable, versatile, suitable for adverse conditions, can be used on various materials and joint types.

- Cons: Slower process, requires more post-weld cleanup.

Gas Metal Arc Welding (GMAW)

- Pros: Versatile, high welding speed, suitable for a wide range of materials.

- Cons: Requires significant equipment setup, may not be suitable for outdoor welding.

Flux-Cored Arc Welding (FCAW)

- Pros: High welding speed, deep penetration, self-shielding capabilities, suitable for outdoor welding.

- Cons: May produce more spatter, flux cleanup required.

Gas Tungsten Arc Welding (GTAW)

- Pros: High-quality welds, excellent control, low heat input, minimal spatter.

- Cons: Requires advanced welding skills, slower process.

Spot Welding

- Pros: High productivity, efficient, widely used in the automotive industry.

- Cons: Limited to joining thin materials, may not be suitable for thicker or dissimilar materials.

Projection Welding

- Pros: Strong and reliable welds, suitable for irregular geometries and thick materials.

- Cons: Projection design complexity.

Seam Welding

- Pros: High-speed welding, consistent and watertight joints.

- Cons: May require specialized equipment, limited joint configurations.

Flash Welding

- Pros: Strong and reliable welds, minimal material distortion.

- Cons: Requires precise control, may not be suitable for all material combinations.

Oxy-Fuel Welding

- Pros: Versatile, simplicity, wide range of materials.

- Cons: Less precision and control compared to other processes.

Plasma Arc Welding

- Pros: High control, excellent weld quality, low distortion, minimal heat-affected zone.

- Cons: Specialized equipment, higher initial costs.

Electron Beam Welding

- Pros: Deep penetration, excellent control, high-quality welds, minimal distortion.

- Cons: Vacuum chambers and specialized equipment required, complex and expensive process.

Laser Welding

- Pros: Precision and control, fast welding speeds, narrow heat-affected zone.

- Cons: High initial costs, safety precautions required.

Cost Considerations

When selecting a welding process, it’s important to consider the cost implications. Each welding process comes with its own set of costs, including equipment, consumables, and maintenance expenses. Some processes may have higher initial costs, while others may require ongoing consumable expenses.

Additionally, specialized processes like electron beam welding or laser welding may involve higher equipment and setup costs. It’s crucial to assess your budget and project requirements to determine the most cost-effective welding process that meets your needs.

Safety Considerations

Welding involves working with high temperatures, electrical currents, and potentially hazardous materials. Safety should always be a top priority when choosing a welding process. It’s essential to have the necessary safety equipment, such as welding helmets, gloves, and protective clothing, regardless of the process chosen.

Some processes, like oxy-fuel welding or plasma arc welding, may involve additional safety considerations due to the use of fuel gases or powerful energy sources. It’s crucial to thoroughly understand the safety requirements and take appropriate precautions to ensure the well-being of yourself and others in the work environment.

Consulting Professionals

If you are unsure about which welding process is best suited for your project, it can be beneficial to consult with welding professionals or experts in the field.

They can provide valuable insights and recommendations based on their experience and knowledge. Consulting professionals can help ensure that you choose the most appropriate welding process for your specific project requirements, reducing the risk of errors or inefficiencies.

Experimentation and Practice

While guidance from professionals is valuable, sometimes the best way to determine the ideal welding process is through hands-on experimentation and practice.

If time and resources allow, consider conducting small-scale tests using different welding methods and materials.

This will not only help you gain experience and confidence in various processes but also allow you to evaluate the quality, productivity, and suitability of each method for your specific project.

Experimentation and practice are essential for continuous improvement and honing your welding skills.

Summary

In summary, selecting the right welding process for your project requires careful consideration of various factors. Material compatibility, thickness, joint type, welding position, and your own skill level all play a role in determining the most suitable welding method.

Arc welding processes, such as shielded metal arc welding, gas metal arc welding, flux-cored arc welding, and gas tungsten arc welding, offer versatility and different characteristics to cater to different project requirements. Resistance welding processes, including spot welding, projection welding, seam welding, and flash welding, provide efficient and reliable methods for various joint configurations.

Other welding processes, such as oxy-fuel welding, plasma arc welding, electron beam welding, and laser welding, offer specialized advantages for specific applications. Considering the pros and cons, cost implications, safety considerations, and seeking professional advice when necessary will help you make an informed decision.

Remember, practice and experimentation are valuable tools for gaining experience and perfecting your welding skills. By carefully evaluating each factor and selecting the most appropriate welding process, you can ensure the success and quality of your welding project.