Are you considering taking up welding as a hobby or profession? Prioritizing safety while working with intense heat and potentially hazardous materials is essential. In this article, we’ll discuss the necessary safety gear for Welding.

We’ll cover all the essentials from protective clothing to specialized equipment to ensure a safe and enjoyable welding experience. When it comes to Welding, one of the most important aspects to consider is your safety. Welding can expose you to various hazards such as sparks, spatter, fumes, and intense heat.

Therefore, it is crucial to have the proper safety gear in place to protect yourself from any potential harm.

In this article, we will discuss the essential safety equipment you need for Welding, covering head protection, eye and face protection, respiratory protection, hand and body protection, foot protection, ear protection, heat and fire protection, electrical safety, fall protection, and additional safety equipment.

Head Protection

Welding Helmet

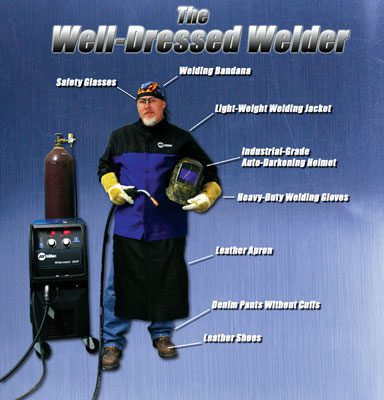

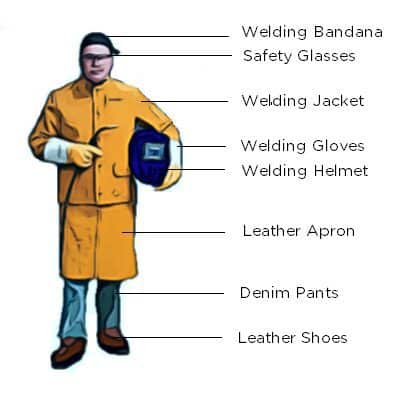

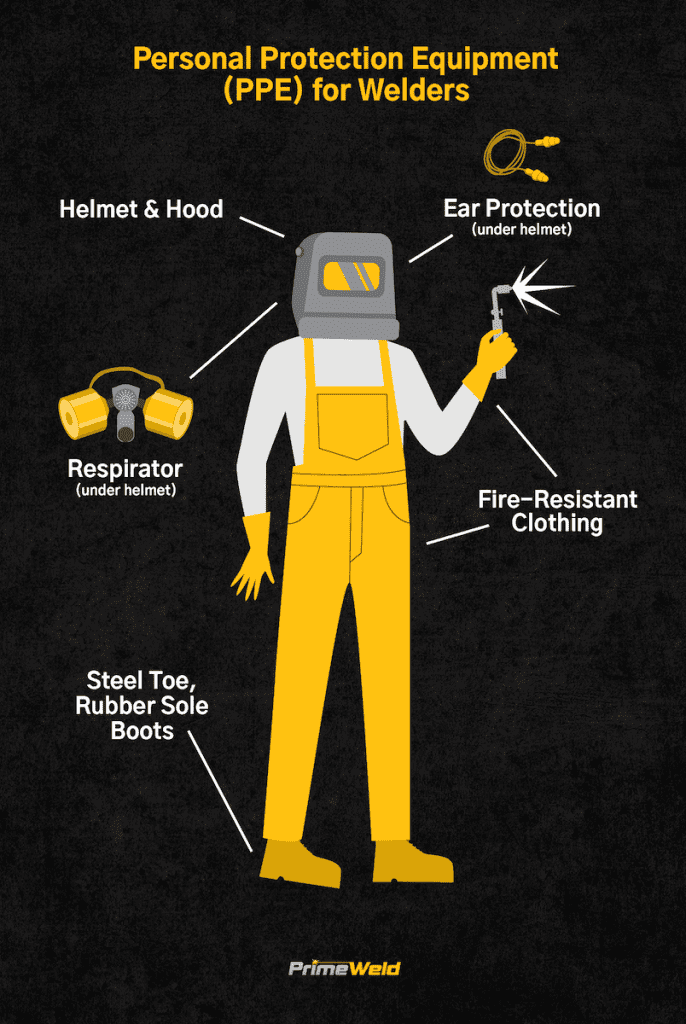

A welding helmet is an absolute must-have for protecting your head during welding projects. It shields your face, eyes, and neck from the intense light, sparks, and UV rays generated during Welding.

A quality welding helmet should have a durable outer shell, a comfortable headband, and an adjustable lens shade. Consider purchasing a welding helmet with an auto-darkening lens, as it provides both convenience and protection by automatically adjusting the shade according to the arc brightness.

Hard Hat

In addition to a welding helmet, wearing a hard hat is essential, especially when falling objects or overhead hazards are present. A hard hat protects against impacts and can save you from serious head injuries.

Look for a hard hat that meets the safety standards and offers a secure fit with an adjustable suspension system. Some hard hats also come with built-in accessory slots, allowing you to attach additional protective equipment like hearing protection or a face shield.

Bump Cap

A bump cap, although not as heavy-duty as a welding helmet or hard hat, can still offer some head protection in less hazardous welding environments.

It is designed to safeguard your head from minor bumps and lacerations caused by low-hanging objects or accidental contact with equipment. If you work in a confined space or any location where head injuries are unlikely but still possible, a bump cap can be a lightweight and comfortable option.

Eye and Face Protection

Welding Goggles

Welding goggles are a crucial piece of equipment for protecting your eyes during Welding. They provide a secure fit around your eyes and offer protection against sparks, spatter, and harmful UV rays.

Look for goggles with a shade number suitable for your welding process and a comfortable strap for a secure fit. Some welding goggles are designed to fit over prescription glasses, ensuring that everyone can enjoy adequate eye protection.

Safety Glasses with Side Shields

Even when wearing a welding helmet or goggles, it is essential to wear safety glasses with side shields for added protection. Safety glasses shield your eyes from flying debris, particles, and even harmful chemicals.

The side shields provide a more comprehensive coverage area and help prevent potential side impacts. Opt for safety glasses that meet the necessary safety standards and ensure a comfortable fit for extended periods of wear.

Welding Face Shield

A welding face shield is an excellent option for additional face protection, especially when working on projects that require overhead Welding or involve intense heat and spatter. It provides full-face coverage, protecting your eyes, face, and neck from sparks, radiant heat, and flying debris.

Look for a face shield with an adjustable headband and a clear, impact-resistant visor. Some face shields also include features like flip-up visors or replaceable lenses for added convenience.

Respiratory Protection

Respirator Mask

Welding produces fumes and vapors that can be harmful if inhaled. Therefore, wearing a respiratory mask is essential for your safety. Respirator masks are designed to filter out particulates, fumes, and gases, providing clean air for you to breathe.

Look for a respirator mask specifically designed for welding applications and offers a proper fit. Choose between disposable or reusable respirators with replaceable filters, depending on your needs and preferences.

Powered Air Purifying Respirator (PAPR)

Consider using a powered air purifying respirator (PAPR) for added respiratory protection and prolonged comfort. A PAPR unit comprises a battery-powered respirator motor and a high-efficiency particulate air (HEPA) filter. It provides a continuous filtered air flow to the respirator, reducing your exposure to fumes and particles.

PAPRs are particularly beneficial when working in confined spaces or poorly ventilated areas. Remember that PAPRs require regular maintenance and filter replacements to function effectively.

Filter Cartridges

If you prefer using a reusable half-face or full-face respirator, make sure to have suitable filter cartridges. The filter cartridges are responsible for capturing and removing specific contaminants from the air you breathe.

Different cartridges are designed to filter out different types of particles or gases. Ensure that the filter cartridges you choose are compatible with your respirator and appropriate for the hazards you may encounter while welding. Remember to regularly replace the filter cartridges according to the manufacturer’s instructions.

Hand and Body Protection

Welding Gloves

Welding gloves are a crucial component of your safety gear, as they protect your hands from sparks, heat, and potential burns.

High-quality welding gloves should be made from flame-resistant and heat-resistant materials like leather or Kevlar. They should fit securely, allowing you to maintain dexterity while providing adequate coverage. Consider gloves with reinforced palms and additional padding for enhanced protection and durability.

Welding Jacket

A welding jacket protects your upper body from sparks and radiant heat. It acts as a barrier between your skin and any potential hazards, reducing the risk of burns and injuries. Look for a welding jacket made from flame-resistant and heat-resistant materials, such as leather or a durable cotton blend. Ideally, the jacket should have cuffs that can be adjusted to fit snugly around your wrists, preventing sparks or particles from entering.

Apron or Bib

When working on welding projects that involve a lot of bending or kneeling, an apron or bib can provide additional protection to your lower body. It shields your legs, thighs, and torso from sparks, spatter, and heat, reducing the risk of burns and skin injuries.

Choose an apron or bib made from a flame-resistant material that offers a comfortable fit. Adjustable straps and fastenings ensure ease of use and allow for a customized fit.

Welding Sleeves

Welding sleeves are an excellent addition to protect your arms from sparks, spatter, and heat radiation. They are typically made from flame-resistant materials and can be worn with a welding jacket or on their own.

Welding sleeves provide coverage from your wrists to your shoulders, minimizing the risk of burns and cuts. Look for sleeves with elastic or adjustable cuffs for a secure fit while allowing freedom of movement.

Welding Pants

Protecting your lower body is just as crucial as protecting your upper body during Welding. Welding pants offer coverage from your waist to your ankles, shielding your legs from sparks, spatter, and heat. They are typically made from flame-resistant and heat-resistant materials, ensuring your safety while providing comfort and flexibility. Consider pants with reinforced knees and additional pockets for added durability and convenience.

Safety Shoes

Wearing safety shoes is essential when it comes to foot protection during Welding. Safety shoes provide impact resistance and feature non-slip soles, preventing accidental slips or falls.

Look for shoes that meet the necessary safety standards and offer proper arch support and cushioning for extended wear. Steel-toed or composite-toed safety shoes are particularly beneficial when working with heavy materials or equipment to protect your toes from potential crushing injuries.

Foot Protection

Welding Boots

For added foot protection and durability, welding boots are a significant investment. Welding boots are designed to protect your feet from sparks, heat, and falling objects.

They are typically made from flame-resistant materials and have reinforced toes and soles. Opt for boots with non-slip soles that provide excellent traction and prevent accidental slips or falls. Choosing welding boots that fit correctly and offer the necessary support for long hours of wear is crucial.

Metatarsal Guards

In addition to welding boots, consider using metatarsal guards for enhanced foot protection. Metatarsal guards cover the front part of your foot, including the metatarsal bones. They protect against crushing injuries, impacts, and falling objects. Metatarsal guards can be attached to your safety shoes or boots, providing extra protection without compromising comfort or mobility.

Ear Protection

Ear Plugs

Welding can generate loud noises that may damage your hearing over time. To protect your ears from constant noise exposure, it is essential to wear earplugs. Ear plugs are small devices that fit into your ear canal, effectively reducing the level of noise that reaches your inner ear.

They are easy to use, portable, and come in various sizes and materials. Disposable foam ear plugs or reusable silicone ear plugs offer sufficient noise reduction and can be a comfortable option for extended periods of wear.

Earmuffs

For additional hearing protection or when working in extremely high noise levels, earmuffs are an excellent option. Earmuffs cover your entire ear and create a seal around it, effectively blocking out noise.

Look for earmuffs with a high noise reduction rating (NRR), adjustable headbands, and cushioned ear cups for added comfort. Some earmuffs also have features like built-in communication capabilities or audio input for listening to music while working.

Heat and Fire Protection

Fire-Resistant Clothing

When welding, it is crucial to wear fire-resistant clothing to protect yourself from potential burns and injuries caused by flames, sparks, or molten metal. Fire-resistant clothing is typically made from treated cotton, wool, or flame-resistant synthetic fibers.

It provides a protective barrier between your skin and any heat source, reducing the risk of burns and heat-related injuries. Look for fire-resistant clothing that meets the necessary safety standards and fits properly to ensure maximum protection.

Heat-Resistant Gloves

In addition to welding gloves, heat-resistant gloves can provide extra protection for your hands when working in high-temperature environments. They are designed to withstand intense heat, allowing you to handle hot materials or objects safely.

Heat-resistant gloves are typically made from Kevlar or treated leather, providing a reliable barrier against heat and flames. Look for gloves with good insulation and a secure fit to ensure optimal protection.

Fire Extinguisher

Having a fire extinguisher readily accessible when Welding is essential to prevent or control any potential fires. Select a fire extinguisher that is suitable for use on Class A, B, and C fires, as these can cover most common fire hazards encountered during Welding.

Ensure that the fire extinguisher is properly maintained, easily accessible, and everyone in the work area knows how to operate it. Regular training on fire safety and appropriate use of fire extinguishers is also highly recommended.

Electrical Safety

Insulated Tools

When working with electrical components or in environments with electrical hazards, using insulated tools is crucial for your safety. Insulated tools have non-conductive handles, protecting you from potential electric shocks or short-circuits. Look for tools with insulated handles that comply with the necessary safety standards. Insulated tools should be regularly inspected for any signs of wear or damage, and any compromised tools should be immediately replaced.

Non-Conductive Gloves

In addition to insulated tools, non-conductive gloves are essential when working with electricity or electrical equipment. Non-conductive gloves act as a barrier, preventing any electrical current from passing through your body.

Look for gloves that are specifically designed for electrical work, providing both shock resistance and good dexterity for handling small components. Non-conductive gloves should fit snugly without compromising your ability to handle tools or perform tasks accurately.

Fall Protection

Safety Harness

When working at heights or in elevated areas, wearing a safety harness is critical to prevent falls and injuries. A safety harness consists of straps and buckles that secure your body and distribute the force of a fall evenly across your shoulders, chest, and legs.

Look for a safety harness that is adjustable, comfortable to wear, and meets the necessary safety standards. Regularly inspect the harness for any signs of wear or damage, and replace any worn-out components immediately.

Safety Lanyard

A safety lanyard is an essential component of fall protection when used in conjunction with a safety harness. It connects your safety harness to a secure anchor point, preventing you from falling to the ground in the event of a slip or stumble.

Look for a safety lanyard that is compatible with your safety harness and has a reliable locking mechanism. Some lanyards come with additional features like energy absorbers or self-retracting lifelines, providing extra protection and ease of movement.

Anchor Point

An anchor point is a secure attachment point to which the safety lanyard is connected. It can be a structural beam, a sturdy anchor post, or a designated anchor point specifically designed for fall protection systems.

Ensure that the anchor point you choose is strong enough to support the potential fall forces and is properly installed according to the manufacturer’s guidelines. Regularly inspect anchor points for any signs of wear or damage, and avoid using any compromised anchor points.

Additional Safety Equipment

Welding Blanket

A welding blanket is a versatile piece of safety equipment that can be used to protect surrounding areas from sparks, spatter, or heat. It is typically made from fire-resistant materials and provides a crucial barrier between your welding project and any combustible materials nearby.

Welding blankets come in various sizes and thicknesses, allowing you to choose the most suitable one for your specific welding applications. Consider using welding blankets to create safe work zones and prevent accidental fires or damage to the working environment.

Spatter Guards

Spatter guards, or spatter shields, are protective devices that can be attached to your welding equipment or workpiece to prevent molten metal spatter from reaching unwanted areas. They are particularly useful when welding in tight spaces or around sensitive components.

Spatter guards can be made from materials like ceramics, wire mesh, or heat-resistant fabrics, providing a reliable barrier against sparks and spatter. Using spatter guards can help reduce the risk of fires, property damage, or injuries caused by hot metal projectiles.

First Aid Kit

Having a well-stocked first aid kit is crucial in any workspace, especially in welding environments where accidents can occur. A first aid kit should include essentials like bandages, sterile dressings, antiseptic solutions, adhesive tape, burn cream, and eye wash solutions.

Familiarize yourself with the contents of the first aid kit and ensure that everyone in the work area knows its location. Regularly check the expiration dates of products and replenish any supplies that have been used or expired to maintain the kit’s efficacy.

In conclusion, ensuring your safety during welding projects is of utmost importance. By having the right safety gear in place, you can protect yourself from potential hazards such as sparks, spatter, fumes, and high heat.

Remember to prioritize head protection with a welding helmet, hard hat, or bump cap. Eye and face protection are equally important and can be achieved through welding goggles, safety glasses with side shields, and welding face shields.

Don’t forget to invest in respiratory protection with a respirator mask, powered air purifying respirator (PAPR), or filter cartridges to safeguard your lungs.

Hand and body protection require the use of welding gloves, a welding jacket, an apron or bib, welding sleeves, welding pants, and safety shoes for a comprehensive shield against sparks, heat, and burns. Foot protection is equally vital and can be achieved with welding boots and metatarsal guards.

Ear protection is crucial in reducing noise-induced hearing loss and can be achieved through ear plugs or earmuffs. Heat and fire protection are essential, and fire-resistant clothing, heat-resistant gloves, and a fire extinguisher should always be accessible. Electrical safety necessitates the use of insulated tools and non-conductive gloves to prevent electric shocks.

Fall protection is crucial when working at heights and requires a safety harness, safety lanyard, and secure anchor points. Additional safety equipment such as a welding blanket, spatter guards, and a first aid kit further enhance your safety during welding projects.

By equipping yourself with the appropriate safety gear, you can weld with confidence, knowing that you have taken the necessary precautions to protect yourself from harm.