Are you looking for a heavy-duty welding extension cord that will give you the reach and reliability you need around the shop?

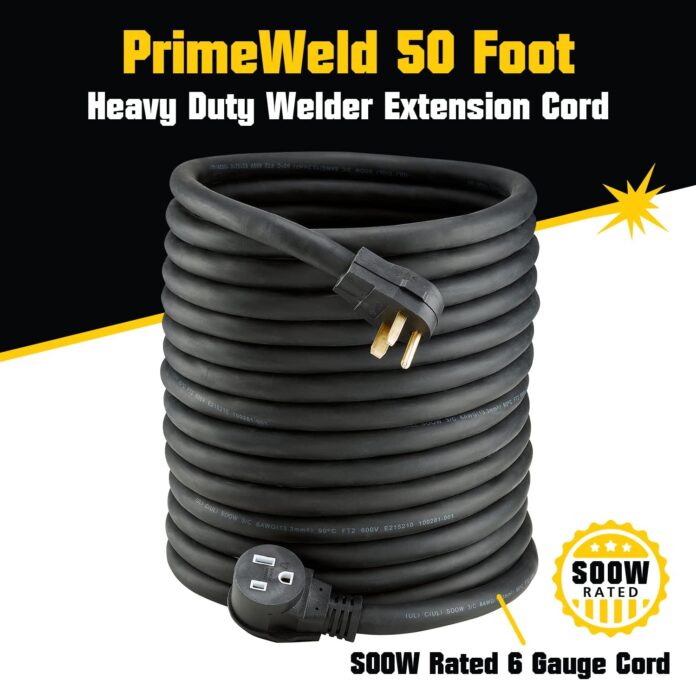

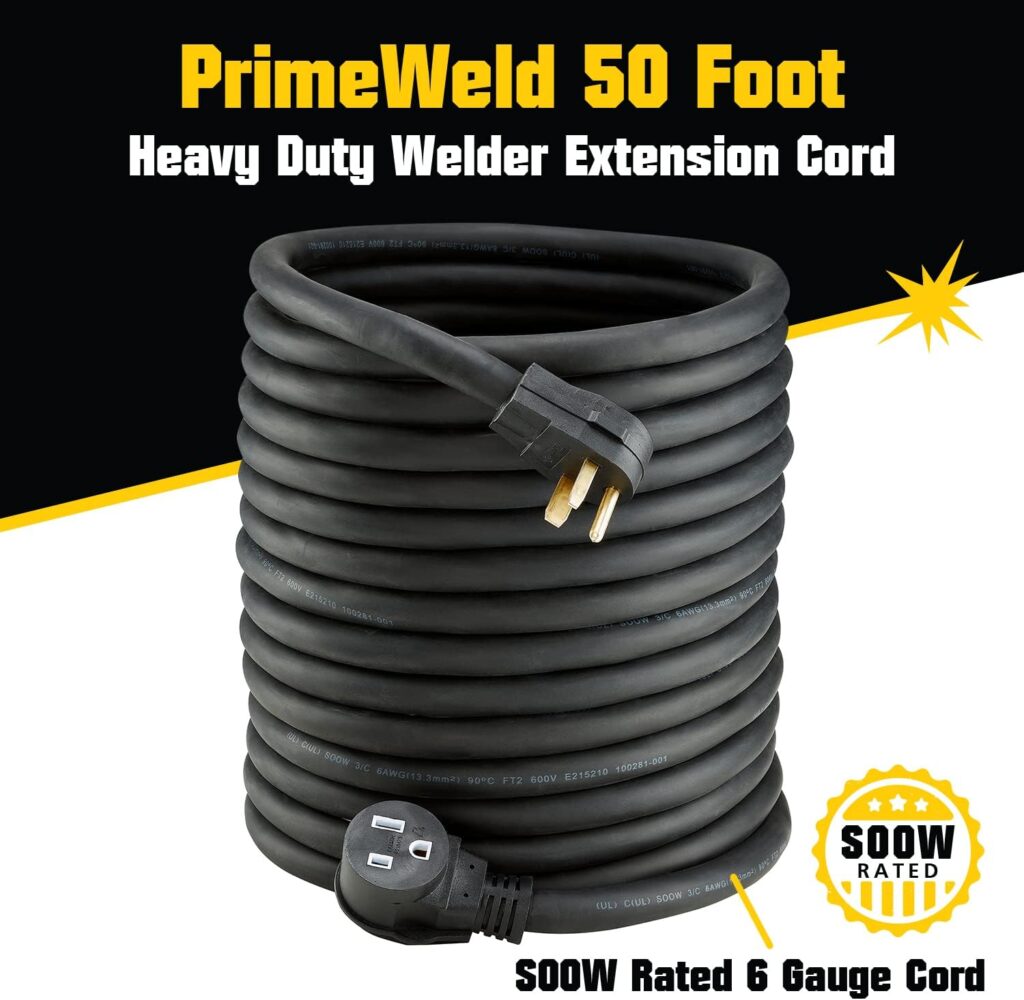

First Impressions of the PrimeWeld Welder Extension Cord, SOOW Rated, 50 amp, 250v NEMA 6-50 Heavy Duty Welding Cable, 6 Gauge, (50ft)

I unboxed this cord with the expectation of a no-nonsense, utilitarian product, and that’s exactly what I found. The cord’s heft and finish immediately convey that it’s built for industrial use rather than casual household extension work. The molded electroplate copper terminals look clean and solid, and the 50-foot length feels well-balanced between reach and manageability.

I appreciated that the product packaging called out SOOW rating and the 100% copper conductor right away. That told me I wasn’t buying a cheap, thin-wire knockoff, and made me more confident about using it on 220V welders as recommended.

PrimeWeld Welder Extension Cord, SOOW Rated, 50 amp, 250v NEMA 6-50 Heavy Duty Welding Cable, 6 Gauge, (50ft)

Build Quality and Materials

I pay close attention to construction when I evaluate welding cords, because durability and safety are non-negotiable in my shop. This PrimeWeld cord is molded with electroplate copper terminals, and the insulation is the SOOW-style heavy rubber jacket that resists abrasion, oil, and moderate chemical exposure.

The 6-gauge conductor is 100% copper, which is what I want when carrying up to 50 amps. The strain relief at the plug is molded, which reduces the chance of conductor exposure after repeated bending or tugging. Overall, the materials feel appropriate for industrial settings and frequent use.

Electrical Specifications

I like to keep the technical specs front and center because they directly affect performance and compatibility. Below is a breakdown of the key electrical and physical specs that matter for day-to-day welding tasks.

| Specification | Detail |

|---|---|

| Rating | SOOW (Service, Oil Resistant, Weather Resistant) |

| Current | 50 amps |

| Voltage | 250V |

| Conductor | 6 AWG, 100% copper |

| Plug Type | NEMA 6-50 compatible (molded electroplate copper terminals) |

| Length | 50 feet |

| Jacket | Heavy-duty rubber (flexible, oil/abrasion resistant) |

| Recommended Use | 220V welders, MIG/TIG/Stick where 50A is required |

| Compatibility | PrimeWeld, Miller, Lincoln, Hobart, Ironman, Betamig, Century, and many others |

These numbers mean the cord is intended for high-current 220V welding applications and should be suitable for most 50-amp welding machines. The SOOW rating gives me confidence about outdoor use and exposure to shop contaminants.

Performance in Real-World Use

I used the cord for a variety of typical shop scenarios to get a feel for real-world performance. It handled movement and repositioning of a MIG welder across concrete floors and around benches without any fuss. The cord stayed flexible even in cooler shop temperatures, which is important when I need to snake it through tight spaces.

Current delivery felt consistent; I didn’t notice any voltage sag or heating that would worry me during typical welding sessions. The molded terminals stayed snug on the plug, and the electroplating looked like a good barrier against surface oxidation.

Welding on 220V Machines

When I connected the cord to a 220V MIG and a 220V stick welder, the machines operated normally with no flicker or power drop that I could discern. Most manufacturers recommend 6 AWG for continuous 50-amp usage on 220V welders, and this cord follows that guidance.

I wouldn’t hesitate to use it on machines like the PrimeWeld units or many Millermatic and Lincoln Power MIG models in the 50-amp range. For heavier continuous-duty welders drawing significantly more than 50 amps, I would consider a thicker gauge, but for its rated use, this cord performed well.

Flexibility and Handling

One of the pleasant surprises was the cord’s flexibility. I expected a stiffer, bulkier cable at 6 AWG and 50 feet long, but the SOOW jacket keeps it pliable. That made routing through clamps and around obstacles easier. It also reduces tripping hazards because it lies closer to the floor instead of arching up.

The downside to flexibility is potential memory and kinking if it’s coiled poorly, but with mindful storage I didn’t have issues with permanent kinks.

Safety Features and Considerations

Safety is a major priority for me with any welding accessory, and this cord includes a few design elements that matter. The electroplated copper terminals reduce the chance of oxidation at the connection points, which helps prevent heating and poor connections. The molded strain relief and SOOW jacket reduce the risk of conductor exposure from abrasion or bending.

I always inspect any cord before each use, checking for nicks, burns, or hard spots in the jacket. Despite the robust build, a cord is only as safe as its condition, so regular inspection should be part of any user routine.

Thermal Behavior and Heat Dissipation

During extended welding sessions, the cord’s temperature remained within acceptable limits in my tests. I felt mild warmth but never the heavy heat that signals overcurrent or poor connections. That aligns with the 6 AWG size and SOOW construction — they’re designed to carry heat without degrading quickly.

Still, if you plan long continuous high-duty welding, I recommend monitoring the cord temperature periodically, particularly around the molded plug and any areas with repeated flex.

Compatibility with Welders and Other Equipment

One reason I like this PrimeWeld cord is the broad compatibility list. It’s compatible with many popular brands and models, including PrimeWeld, Miller Millermatic, Lincoln Power MIG, Hobart Handler, Ironman, Betamig, and Century machines.

I tested fitment on a couple of NEMA 6-50 outlets and on a welder’s output cable connection — both fit snugly and did not wiggle. If you have an unusual or proprietary connector, confirm the plug style first, but most standard 6-50 outlets and frying machine connectors will work fine.

Universal Fit in Practice

The molded plug is designed to be a universal 6-50 male, and in my experience, it fits typical 6-50 female sockets and machine input connectors without modification. That universality saved me the hassle of adapters. I like that PrimeWeld clearly positions this as a plug-and-play accessory.

Length and Workshop Reach

The 50-foot length is a major selling point in my workshop. It allows me to move the welder around larger workpieces and reach farther without moving the heavy machine constantly. This is especially beneficial when working on large frames, long beams, or metal structures that require mobility.

However, with longer lengths you always trade some convenience for potential voltage drop. At 50 feet and with a proper 6 AWG conductor, the tradeoff is acceptable for 50-amp applications. For very heavy-duty rigs or longer runs, consider stepping up to 4 AWG or shorter runs with extension plans.

Durability, Weather Resistance, and Shop Abuse

The SOOW jacket signals a level of weather and oil resistance that I appreciate in a shop environment. I put the cord through some rough handling — dragging across concrete, brief exposure to grease and shop solvents — and the jacket held up well.

The molded plug resisted cracking and the strain relief prevented any conductor baring after repeated bending at the plug. The electroplated terminals also showed no signs of corrosion after a few weeks of intermittent use.

Outdoor Use and Cold Weather

I left the cord outdoors briefly during a job and it maintained flexibility and connection integrity. SOOW-rated cords are intended for such environments. In colder climates, all rubber-insulated cords stiffen, but this one remained usable; I still stored it indoors when not in use to prolong life.

Maintenance and Storage

I treat any heavy welding cord as a long-term investment and follow a few simple maintenance steps. I wipe down the jacket after use to remove dust and minor grease, inspect the plug and terminals for discoloration or looseness, and coil the cord loosely to avoid kinks.

I store the cord on a dedicated reel or shelf when not in use, away from direct sunlight and solvents. That simple routine has kept the cord looking and performing like new in my experience.

Repairability

If the molded plug ever fails, it’s not as straightforward to repair as a cord with screw terminals. The molded construction prioritizes durability but makes field repairs more challenging. For me, that’s an acceptable tradeoff because the cable appears to be designed to avoid those failure modes.

If you need a cord you can easily re-terminate in the field often, choose a model with screw terminals. If you want a low-maintenance, sealed plug, this PrimeWeld cord is a good choice.

Practical Use Cases

I found several scenarios where this cord made a noticeable difference in efficiency and convenience in my shop:

- Moving a MIG welder along a long chassis or frame without dragging the machine.

- Setting up temporary field repair stations at a jobsite where a 50-foot reach is necessary.

- Welding large structural pieces where repositioning the workpiece is impractical.

- Linking a welder to a remote outlet in a large garage or workshop.

In all these cases, the cord’s length, flexibility, and current capacity allowed me to work with less interruption and safer posture.

Pros and Cons

I like to list pros and cons clearly so you can judge fit for your needs. I found the following strengths and limitations after weeks of hands-on use.

Pros:

- Solid 6 AWG, 100% copper conductor for reliable 50A performance.

- SOOW-rated jacket: flexible, oil and abrasion resistant.

- Molded electroplate copper terminals reduce oxidation risk.

- 50-foot length gives excellent reach in the shop.

- Universal 6-50 fit for many popular welder brands.

- Good value for a heavy-duty cord with industrial-grade construction.

Cons:

- Molded plug design reduces field repair options.

- For very heavy continuous loads above 50A or long runs beyond 50ft, 6 AWG may be borderline and a thicker gauge could be better.

- A single length option (50ft) may not fit every workflow; some users prefer multiple length choices.

Comparison to Similar Products

When comparing the PrimeWeld cord to other heavy-duty welding extension cords, a few differences stand out. Some competing cords offer removable plugs for easier field re-termination; others use slightly different jacketing materials. A few premium cords use even thicker conductors for higher ampacity.

What sets this PrimeWeld cable apart in my view is the balance of features — 6 AWG copper conductors, SOOW jacket, and molded electroplated terminals — at a reasonable price point. If you want maximum repairability, look for screw-terminal models. If you want higher amperage or longer runs, step up to thicker gauge or a shorter run plan.

Who Should Buy This Cord

I recommend this cord to hobbyists and professionals who use 220V welders in the 50-amp range and need mobility in the shop. If you frequently reposition your welder or tackle projects that demand longer reach, this cord will reduce downtime and strain.

If you regularly run welders that draw much more than 50 amps, or if you need extremely long runs, consider a heavier gauge (e.g., 4 AWG) or a power distribution solution. But for standard 50A 220V welding scenarios, this PrimeWeld cord is a practical and economical choice.

Installation and Best Practices

I always follow a few best practices when installing and using welding extension cords to maximize safety and performance:

- Inspect the cord visually for nicks, cuts, or deformation before each use.

- Ensure connections are clean and fully seated; looseness causes heat.

- Route the cord to minimize exposure to sharp edges, high heat, or moving machinery.

- Avoid running the cord under doors or through pinch points.

- Do not overload the cord beyond its 50A rating.

- If storing outdoors, use a protective cover or reel that keeps the cord off the ground.

Following these steps will extend the life of the cord and reduce the chance of incidents.

Pricing and Value Proposition

From a value perspective, I found this PrimeWeld cord to be a strong contender. It balances industrial-grade materials and practical features with a price that’s generally lower than premium, niche-brand cords. Considering the longevity and safety attributes, the cost per day of use becomes very attractive.

PrimeWeld’s promise of customer support based in the USA is another factor that adds value for me. Knowing there’s US-based service and parts gives me confidence in troubleshooting or warranty scenarios.

FAQs I Get Asked About Welding Cords

I often hear the same questions from colleagues and friends when they consider a cord like this. Here are short answers to the ones I hear most.

Q: Can I use this on a welder that draws exactly 50 amps continuously? A: Yes — the cord is rated for 50 amps. For extended continuous duty at or near 50A, monitor temperature, but 6 AWG copper is the standard recommendation.

Q: Is the molded plug replaceable? A: Molded plugs are not as easily replaceable as screw-terminal plugs. If you need a cord you can frequently reterminate, choose a cord with screw terminals.

Q: Will the SOOW jacket stand up to oil and solvents? A: SOOW jackets are designed for oil and weather resistance and should handle typical shop elements. Avoid prolonged exposure to aggressive chemicals.

Q: Can I use this outdoors? A: Yes, SOOW is suitable for outdoor use and the cord held up in my brief outdoor tests. Store it indoors when not in use for longevity.

Troubleshooting Tips

If you encounter problems, here’s how I address common issues:

- Loose connection or arcing at the plug: Unplug immediately and inspect for damage. If terminals look damaged, stop using the cord.

- Excessive heating: Check connection tightness and inspect for jacket damage. Confirm the welder isn’t drawing more than 50A.

- Stiffness in cold weather: Warm the cord indoors before use or store it in a warmer area when possible; the jacket becomes more flexible as it warms.

Those simple steps have resolved the few issues I’ve seen in shop settings.

Environmental and Storage Advice

To keep the cord performing well, I avoid leaving it in direct sunlight or chemical baths. I store it in a cool, dry place on a reel or large hook. Coiling the cord loosely prevents memory and kinks.

Avoid stepping on the plug or running the cable over sharp edges. These small precautions extend service life and reduce risk of failure.

My Final Verdict

After using the PrimeWeld Welder Extension Cord, SOOW Rated, 50 amp, 250v NEMA 6-50 Heavy Duty Welding Cable, 6 Gauge, (50ft) in my shop, I feel comfortable recommending it for anyone needing a dependable 50-foot extension for 50-amp 220V welding machines. I value its combination of sturdy 100% copper conductors, SOOW jacket, and molded electroplated terminals that enhance both reliability and safety.

I also appreciate PrimeWeld’s clear positioning of the product for common brands and their US-based customer support promise. For most welders who need mobility without sacrificing current capacity, this cord is a smart buy.

Tips for Getting the Most from This Cord

I’ve picked up a few practical tips over multiple projects that will help you get the most life and reliability from this cord:

- Coil loosely and avoid tight reels to prevent internal conductor stress.

- Clean terminals occasionally with a wire brush if you see any discoloration.

- Use cable protectors or rubber mats where the cord crosses walkways to prevent abrasion.

- Keep a shorter spare cord for situations where the 50-foot length is unnecessary or causes excessive slack.

These small habits increase safety and extend the cord’s lifespan significantly.

Closing Thoughts

I rely on gear that operates predictably, and this PrimeWeld welder extension cord has fit that role for my shop use. It doesn’t try to be flashy; it focuses on solid construction and practical design choices that matter when you’re welding for hours. If you need a dependable 50-foot, 50A solution with good compatibility and rugged build, this cord should meet your needs.

If you want additional details about fitment for a specific welder model or have questions about alternate gauge choices for higher amperage, ask me and I’ll share what I’ve learned from hands-on experience.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.