Imagine you’re embarking on a welding project, and you’re faced with a choice – stick welding or MIG welding?

Both techniques have their advantages, and it’s essential to understand the key differences to make an informed decision.

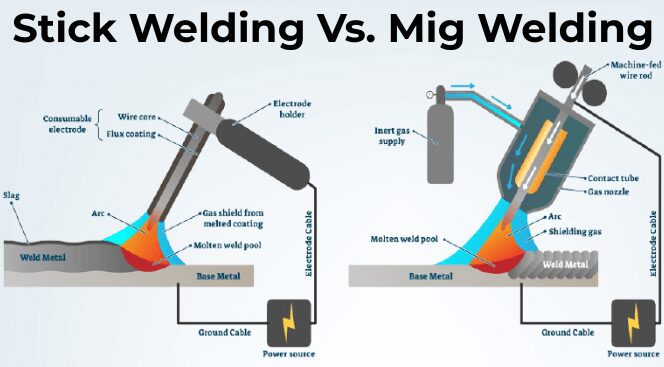

Stick welding, also known as shielded metal arc welding, is a traditional method that uses a consumable electrode coated in a flux to create a weld.

On the other hand, MIG welding, or metal inert gas welding, employs a wire electrode fed from a spool and a shielding gas to protect the weld.

In this article, we’ll explore the dissimilarities between these two popular welding techniques to help you choose the right one for your next project.

Overview of Stick Welding and MIG Welding

Stick welding and MIG welding are two popular welding techniques used in various industries and applications.

Both processes involve joining metals together using heat. Still, they differ in the welding process, equipment used, power source, electrodes or wire, shielding, welding positions, weld quality and appearance, skill level required, cost, and applications.

Definition of Stick Welding

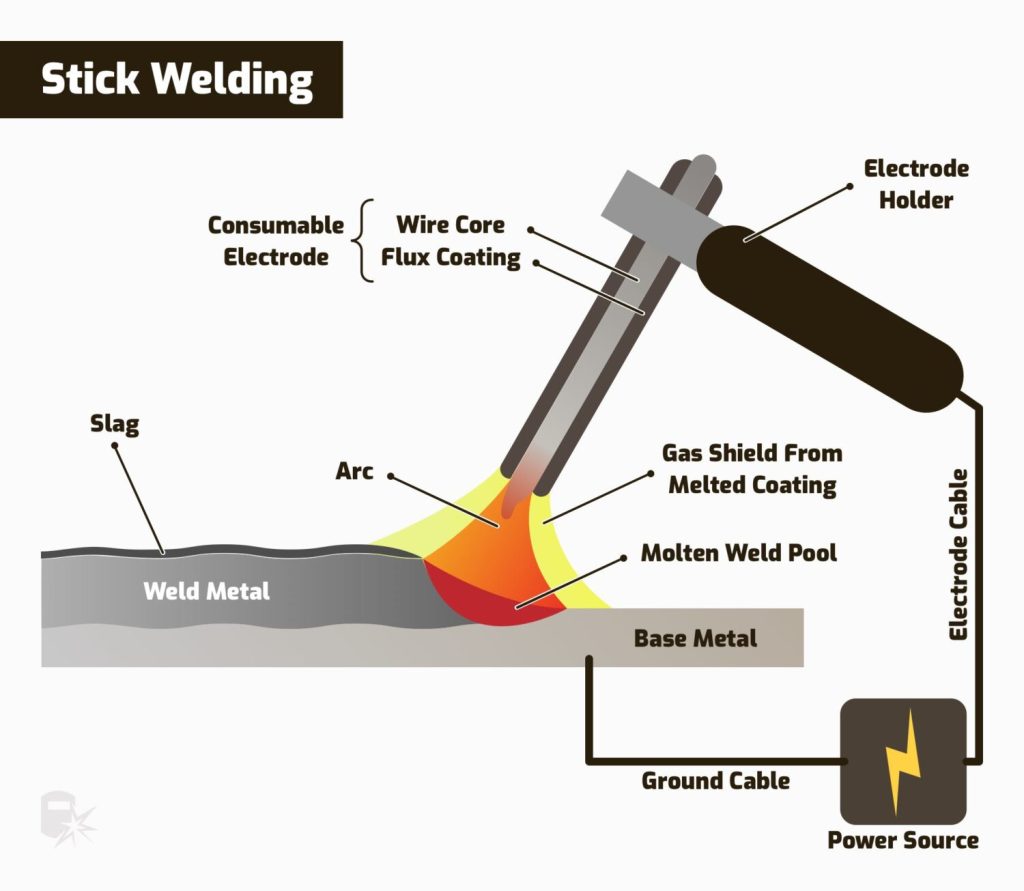

Stick welding, also known as shielded metal arc welding (SMAW), is a manual process in which an electric arc is formed between a flux-coated electrode and the workpiece.

The electrode is made of a metal core wire coated with flux, generating a protective gas shield during welding. Stick welding is commonly used for construction, repairs, and maintenance due to its portability and versatility.

Definition of MIG Welding

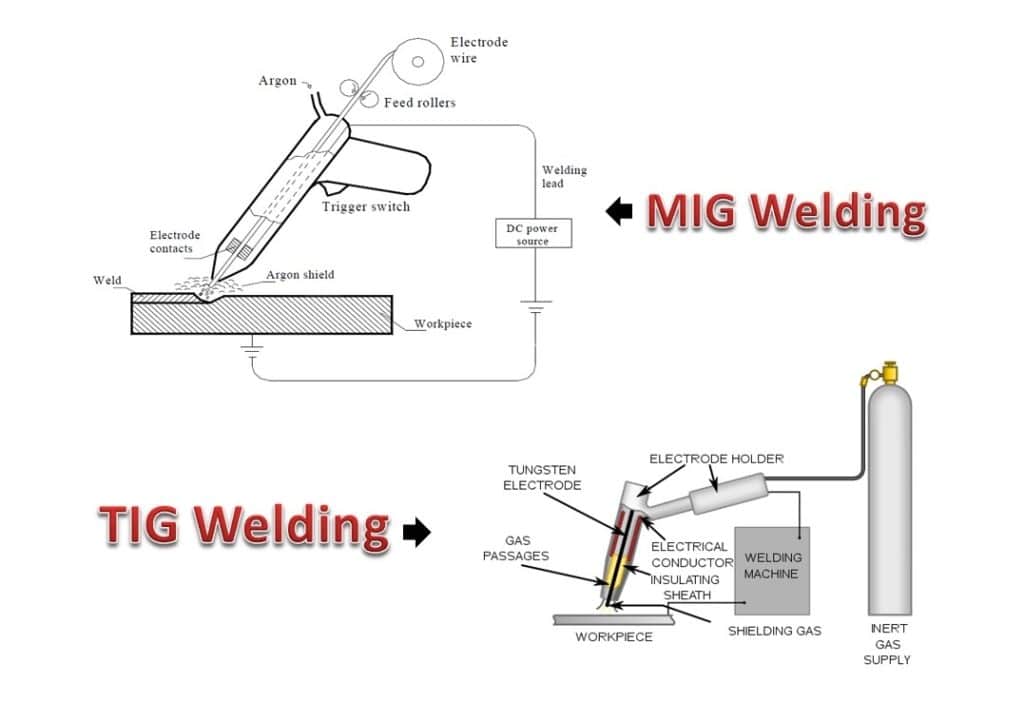

MIG welding, short for metal inert gas welding, is an arc welding process that uses a continuous solid wire electrode and an inert gas to shield the arc and the weld pool.

In this process, the wire is fed continuously from a spool, and the welding machine produces a constant voltage supply. MIG welding is known for its speed, efficiency, and ease of use, making it suitable for high-production applications such as automotive manufacturing.

Brief History of Stick Welding

Stick welding has a long history, dating back to the early 20th century when it was introduced as a manual process.

The first commercially successful arc welding process, stick welding, gained popularity due to its simplicity and versatility. Over the years, advancements in electrode design, welding machines, and power sources have improved the efficiency and quality of stick welding.

Brief History of MIG Welding

MIG welding was developed in the 1940s to increase productivity in the manufacturing industry. It was initially used for welding non-ferrous metals such as aluminum and magnesium.

Over time, improvements in wire feed systems, power sources, and shielding gases have made MIG welding a widely used for various materials, including steel, stainless steel, and copper alloys.

Process and Equipment

Stick Welding Process

In stick welding, the welder manually holds the electrode and continuously moves along the joint to create a molten weld pool. The flux coating on the electrode melts and generates a protective gas shield that covers the weld, preventing contamination.

The welder controls the heat input and penetration by adjusting the distance between the electrode and the workpiece. Stick welding can be performed in various positions, including flat, horizontal, vertical, and overhead.

MIG Welding Process

MIG welding involves using a welding gun that feeds a continuous wire electrode into the welding arc. The welder holds the gun and directs the wire and shielding gas to the joint.

The electrode melts, creating a weld pool, while the shielding gas protects the weld from atmospheric contamination. MIG welding is typically performed in flat and horizontal positions, although vertical and overhead welding can be achieved with proper technique and equipment.

Stick Welding Equipment

Stick welding requires a welding machine, electrodes, an electrode holder, cables, and a power source.

The welding machine generates the necessary current (AC or DC) to strike and maintain the arc, while the electrodes provide filler metal and flux. The electrode holder securely grips the electrode, and cables connect the welding machine to the workpiece.

MIG Welding Equipment

MIG welding equipment includes a welding machine, a welding gun, a wire feeder, a shielding gas cylinder, and a power source.

The welding machine produces the required voltage and current to create the arc, while the welding gun controls wire feeding and gas flow. The wire feeder supplies the continuous electrode wire from a spool, and the shielding gas cylinder provides the inert gas that shields the weld.

Power Source

Stick Welding Power Source

Stick welding can be performed using AC (alternating current) or DC (direct current) power sources.

AC power sources are primarily used for welding iron and steel, while DC power sources are suitable for a broader range of materials, including stainless steel, aluminum, and cast iron. Depending on the specific welding application, both power sources have advantages and limitations.

MIG Welding Power Source

MIG welding typically uses DC power sources, providing a more stable arc and better control over the welding process.

DC power sources are available as either constant voltage (CV) or constant current (CC) machines. Constant voltage machines are commonly used for MIG welding, as they provide a consistent voltage output that ensures a smooth and controlled arc.

Electrodes and Wire

Stick Welding Electrodes

Stick welding electrodes, or welding rods, consist of a metal core wire coated with flux. The flux coating performs multiple functions, including generating the shielding gas, providing alloying elements, removing impurities, and stabilizing the arc.

Electrodes are classified based on their composition and intended use, and different types of electrodes are available for welding various materials and positions.

MIG Welding Wire

MIG welding uses a continuous solid wire electrode of a specific alloy or material. The wire is fed through a welding gun and melted to form the weld pool.

Different types of MIG welding wires are available for welding various materials, such as mild steel, stainless steel, and aluminum. The wire selection depends on the material thickness, desired weld strength, and desired appearance.

Shielding

Stick Welding Shielding

Stick welding relies on the flux coating on the electrode to generate a shielding gas that protects the molten weld pool. When heated, the flux coating releases gases and compounds, creating a protective atmosphere around the weld. This shielding gas prevents atmospheric contamination, such as oxygen and nitrogen, that can cause defects in the weld.

MIG Welding Shielding

MIG welding uses an inert gas, such as argon or helium, to shield the weld from atmospheric contamination. The gas is delivered through the welding gun along with the electrode wire.

In some cases, a combination of inert and active gas (such as carbon dioxide) may be used to achieve specific welding characteristics. The choice of shielding gas depends on the material being welded and the desired weld properties.

Welding Positions

Stick Welding Positions

Stick welding can be performed in various positions, including flat, horizontal, vertical, and overhead. Each position requires techniques and electrode angles to ensure proper fusion and penetration. Welders skilled in stick welding must be able to adapt their technique to accommodate different positions and produce high-quality welds.

MIG Welding Positions

MIG welding is commonly performed in flat and horizontal positions, as the continuous wire electrode tends to sag under the force of gravity in vertical and overhead positions. However, using proper equipment and techniques, MIG welding can also be performed in vertical and overhead positions. The choice of welding position depends on the specific application and the welder’s skill level.

Weld Quality and Appearance

Stick Welding Quality and Appearance

Stick welding can produce welds with good strength and durability when performed correctly. However, the appearance of stick welds may vary depending on factors such as welder skill, electrode type, preparatory cleaning of the workpiece, and welding conditions. Stick welds typically have a distinct “rippled” appearance due to the manual nature of the process.

MIG Welding Quality and Appearance

MIG welding is known for producing clean and aesthetically pleasing welds: the continuous wire electrode and precise control over heat input result in consistent weld appearance and minimal splatter. MIG welds often have a smooth, uniform bead appearance, making them suitable for applications where visual appearance is essential, such as automotive and architectural applications.

Skill Level and Ease of Use

Stick Welding Skill Level and Ease of Use

Stick welding requires a certain level of skill and practice to achieve satisfactory results. The process’s manual nature, including the electrode’s continuous movement and the need to maintain proper arc length, requires a steady hand and good hand-eye coordination. However, once mastered, stick welding offers versatility and the ability to weld in various conditions, including outdoor and remote locations.

MIG Welding Skill Level and Ease of Use

MIG welding is considered easier to learn and operate compared to stick welding. The continuous wire feed and the automatic shielding gas make MIG welding more forgiving and require less manual dexterity.

With proper training and practice, novice welders can quickly become proficient in MIG welding, making it suitable for high-production environments where efficiency and consistency are critical.

Cost

Stick Welding Cost

Stick welding is generally more affordable in terms of equipment and consumables. Stick welding machines are relatively inexpensive compared to MIG welding machines, and the electrodes or welding rods are also affordable.

However, stick welding may require additional costs for electrode storage, as moisture can affect them and needs to be kept in a controlled environment.

MIG Welding Cost

MIG welding equipment, including the welding machine, wire feeder, and shielding gas cylinder, tends to be more expensive than stick welding equipment.

The continuous wire electrode used in MIG welding is also more expensive than stick welding electrodes. Additionally, shielding gas consumption in MIG welding increases the overall cost compared to stick welding.

Applications and Industries

Stick Welding Applications and Industries

Stick welding is widely used in various industries, including construction, infrastructure, and repairs. It is suitable for welding thick materials like structural steel, shipbuilding, and pipelines.

Stick welding also finds applications in manufacturing and fabrication, automotive repairs, and general maintenance. The portability and versatility of stick welding make it a popular choice for outdoor and remote welding projects.

MIG Welding Applications and Industries

MIG welding’s speed, efficiency, and clean weld appearance make it suitable for high-production applications. It is commonly used in the automotive industry for vehicle manufacturing, body repairs, and customization.

MIG welding is also employed in aerospace, metal fabrication, robotics, and furniture manufacturing industries. The ability to weld different materials, such as stainless steel and aluminum, further expands the scope of MIG welding applications.

In conclusion, stick welding and MIG welding have unique characteristics and advantages. Stick welding offers versatility, affordability, and the ability to weld in various positions. On the other hand, MIG welding provides speed, efficiency, ease of use, and clean weld appearance.

The choice between stick welding and MIG welding depends on factors such as the specific welding application, the materials being welded, the desired weld quality and appearance, the skill level of the welder, and the available resources and budget.