Welcome to the world of welding, where sparks fly and metal melds! If you’ve ever wondered about the fascinating process behind joining metals, you’re in for a treat.

In this blog post, we’ll dive into the exciting realm of MIG welding – a technique that has revolutionized metal fabrication.

Whether you’re a DIY enthusiast or a professional welder looking to expand your knowledge, understanding MIG welding is essential.

We’ll cover everything from its unique process to its advantages and disadvantages.

So grab your safety goggles, and let’s get started on this illuminating journey into the art of MIG welding!

The MIG system emerged after developing inert gas welding and creating the TIG torch.

From 1948 to date, this type of welding has been widely used.

TIG and MIG are well known and used; However, their differences distinguish them.

MIG welding is a short circuit that, with its characteristics, will generate a new piece due to the fusion of metals.

MIG Welding Process

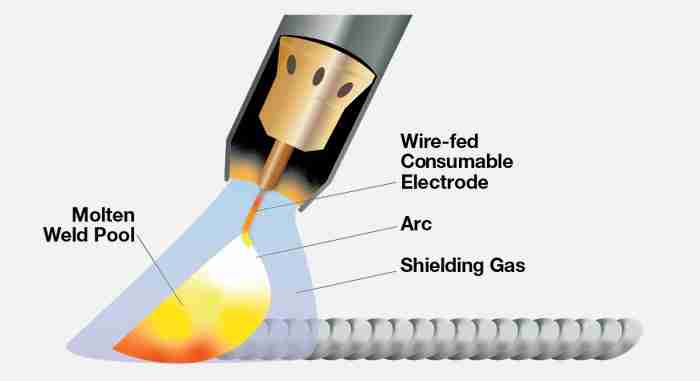

The MIG welding process, or Gas Metal Arc Welding (GMAW), is a versatile and widely used method for joining metals. It involves using a consumable electrode wire that provides the filler material and electrical current to create the weld.

To begin, a power source supplies electricity to the welding gun, containing a contact tip to which the electrode wire is fed. Simultaneously, an inert gas, such as argon or helium, is released through the nozzle to shield the molten metal from atmospheric contamination.

As you pull the trigger on the welding gun, an electric arc forms between the electrode wire and base metal.

This high-temperature arc melts both materials together while depositing filler metal into the joint. The melted electrode wire acts as a protective shield against oxidation and ensures a strong bond between metals.

MIG welding’s greatest strength is its ability to quickly join various types of metals like steel, aluminum, stainless steel, and copper alloys.

Additionally, it offers excellent control over heat input due to adjustable voltage settings on most machines. This versatility makes MIG welding suitable for automotive repairs to construction projects.

However, mastering MIG welding requires practice and skillful technique. Achieving proper weld penetration and avoiding common issues like porosity or excessive spatter can be challenging for beginners. Maintaining proper travel speed and ensuring adequate shielding gas flow throughout each weld is essential.

In conclusion (remember, not concluding), understanding how MIG welding works sets you up to tackle diverse projects requiring strong metal joints. With practice and attention to detail in controlling heat input and shielding gas flow rate(s), you’ll be well on your way to becoming a proficient MIG welder! So keep experimenting with different materials and techniques – let your creative spark along with those electrifying arcs!

MIG or GMAW welding

Referring to it as GMAW welding will probably be understood only by those who know the area very well. In daily use, MIG is the term managed.

However, its initials refer to an arc welding process with inert gas metal.

Metal Inert Gas or Arc Welding Metal Gas refers to a fusion process achieved by an electric arc formed by a metal electrode and the part to be welded.

MIG uses inert gas to protect against the effect of oxidation of the atmosphere on the electrode, which in this type of welding is a welding wire.

Unlike TIG welding, in which the tungsten electrode is not consumable, the wire is consumed by melting, with the part being welded in MIG.

The gas used is argon or a mixture of it with CO2. For welding protection, before undertaking the procedure, ensure that the tank has sufficient gas capacity and everything is in order with its hoses.

Read Next – Best MIG Welding Machine – Buyer Guide and Review

The necessary equipment for MIG welding

This type of welding requires certain specific equipment to have optimal results. Let’s start with the guns.

These have a system of traction and thrust that, when activated, gives way to gas, current, and wire. The latter can be pulled or pushed.

Some guns bring the reel of wire incorporated, allowing welding to meters of the equipment.

A characteristic of the steel wire is its copper cladding.

The wire is usually of three types: solid wire for use with protective gas, tubular wire with a core of mineral powders also used with protective gas, and tubular wire without gas with a core of dust that releases gas burning.

The use of this last wire is without gas.

The gas tank is commonly full of argon; however, helium or a mixture can be used for specific thicknesses.

To control the proper gas output flow, regulators such as the pressure gauge and the flowmeter fulfill the pressure’s function.

In the same way and relation to the same aspect, gas and water conduct hoses are necessary.

The rectifiers and converters are responsible for generating the necessary direct current and a cable with the appropriate caliber and will conduct it according to the amperage.

Read Next – Best Welding Wire Available

Advantages of MIG Welding

MIG welding, also known as Gas Metal Arc Welding (GMAW), offers several advantages, making it a popular choice among welders. Let’s explore some of the critical benefits of this welding process.

MIG welding is highly versatile and can be used to weld various materials, including mild steel, stainless steel, and aluminum. This flexibility makes it suitable for various automotive, construction, and manufacturing applications.

Another advantage of MIG welding is its speed and efficiency. The continuous wire feeding system allows for rapid filler metal deposition, resulting in faster completion than other welding methods. Moreover, the automatic nature of this process reduces the need for frequent starts and stops during longer welds.

Additionally, MIG welding produces clean and precise welds with minimal spatter. The shielding gas in this process protects the molten pool from contaminants in the atmosphere while ensuring excellent arc stability. As a result, MIG-welded joints exhibit superior aesthetics and require less post-weld cleaning or grinding.

Furthermore, MIG welding is relatively easy to learn and operate. With proper training and practice, even novice welders can quickly master this technique due to its simplicity compared to other forms of arc welding. This accessibility makes it ideal for beginner-level enthusiasts or those who need to complete projects quickly without compromising quality.

Last but not least important is the cost-effectiveness associated with MIG welding. While initial equipment costs may be higher than other methods like a stick or Tungsten Inert Gas (TIG) welding, long-term savings are realized through increased productivity due to shorter setup time and reduced material waste.

MIG welding processes

It is a versatile weld applied to aluminum alloys, non-ferrous materials, and thin to medium-thickness steel.

Before starting the welding procedure, essential adjustments must be made.

The current intensity influences the heat input, dimension, and weld penetration depth.

The arc voltage controls its profile, and the feed speed of the wire controls its intensity.

Adjusting and controlling these parameters can be made semi-automatically, automatically, or robotically.

The robotic process is used at the industrial level, where a robot executes the programming.

The automatic form occurs when all adjustments are made previously, and the semi-automatic occurs when combining a previous adjustment with the manual drag of the welding gun.

Read Next – MIG Vs. TIG Welding

Displacements and characteristic movements

In MIG welding, the ideal position of the gun is horizontal.

In this position, it is achieved that the action of the protective gas is optimal, and the smooth cords look good.

The most common displacement of the gun is from right to left, especially when welding aluminum.

This displacement is recommended to achieve better cords in quality and penetration in fine and medium thicknesses.

As for the movements, imagine that pieces are sewn together to join them.

The welding can be linear, circular, impulse, or pendular.

The liner is perfect for use in thin plates for root cords.

The circular movement is adequate when the separation between the edges is significant since a wide cord will prevent penetration.

Pulse welding is done with little material supply when thin cords are needed for slight separations between the edges.

If the separation to be welded is substantial, then the recommended movement is the pendulum.

In it, quite wide cords are drawn that demand considerable material contribution.

Read Next – GOPLUS MIG 130 Welding Machine

Advantage

MIG welding has numerous advantages but also clear limitations.

Among its advantages can be mentioned:

- Large cords can be made without interruption or discontinuity. In this way, a good finish is achieved.

- The wire reel is in the welder, and the rollers push it, allowing us to avoid wasting timreplacingce electrodes.

- The efficiency of the electrode is calculated at 98 percent.

- It can be welded in any position without affecting excellent penetration.

- Welding in thin thicknesses is very easy.

- It produces a few splashes and a clean welded surface.

Read Next – Best Welding Safety Tools – Welding Safety Equipment

Limitations

As stated earlier, it also has limitations that MIG welding must consider before deciding on a MIG welding procedure.

Some are:

- The equipment and technique are complex, demanding only skilled labor.

- The use of a gas tank makes it less portable.

- The cost of the equipment is much higher.

- Outdoor work is not recommended since air currents could cause the gas shield to exit the arc.

- For a good effect, MIG welding cannot use on rusty surfaces or dirty.

Considering all these limitations will make the MIG welding procedure successful and safe.

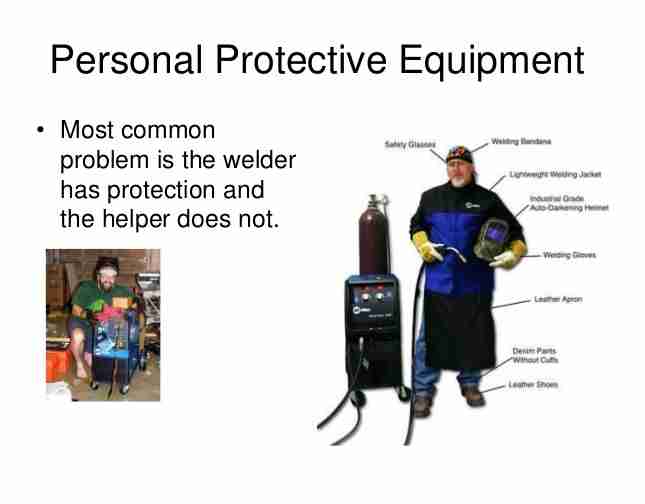

It is worth remembering that when contemplating high temperatures and exposure to ultraviolet rays, the operator’s protective equipment must be head to toe.

Read Next – Top 5 Best Welding Tools Our Top Picks

Important Points to Remember

- Safety First: Regarding MIG welding, safety should always be your top priority. Wear the appropriate protective gear, including a welding helmet, gloves, and flame-resistant clothing. Also, ensure you work in a well-ventilated area to avoid inhaling toxic fumes.

- Choose the Right Wire and Gas: Selecting the correct wire diameter and type for your project is crucial for achieving quality welds. Additionally, using the appropriate shielding gas (such as argon or a mixture of gases) can significantly impact weld penetration and overall performance.

- Cleanliness Matters: Before starting any welding job, thoroughly cleaning the metal surface is essential. Remove rust, paint, or contaminants with a wire brush or grinder to ensure proper fusion between the base material and filler metal.

- Control Your Settings: Understanding how voltage settings and wire feed speed affect your weld is critical to producing consistent results. Experimenting with various settings on scrap pieces before tackling your main project can help you find the optimal parameters.

- Practice Makes Perfect: Like any skill, MIG welding requires practice to master techniques such as maintaining a steady hand position and controlling travel speed accurately. Regularly honing your skills will lead to improved proficiency over time.

Remember these important points when embarking on a MIG welding journey! Stay safe while enjoying this versatile welding process that allows you to create strong bonds between various metals effortlessly!

Difference Between MIG and MAG Welding

MIG welding and MAG welding are commonly used, but what sets them apart? Let’s explore the key differences between the two.

MIG stands for Metal Inert Gas, while MAG stands for Metal Active Gas. The main distinction lies in the type of shielding gas used during the process. MIG welding uses inert gases like argon or helium to protect the weld pool from atmospheric contamination. On the other hand, MAG welding employs active gases such as carbon dioxide or a mixture of carbon dioxide and oxygen.

The choice of shielding gas affects various aspects of the welding process. For instance, MIG welding with inert gases produces cleaner welds with reduced spatter. It is ideal for non-ferrous metals like aluminum and stainless steel because it prevents oxidation. Conversely, MAG welding is often preferred for ferrous materials as it generates more heat and provides better penetration.

Another difference lies in their applications. MIG welding is widely used in automotive manufacturing, construction, and fabrication industries due to its versatility and ease of use. Meanwhile, MAG welding finds extensive application in heavy machinery production, shipbuilding, and structural steelwork where stronger welds are required.

While both processes share similarities and produce high-quality welds when executed correctly by skilled operators, understanding these nuances helps determine which method suits specific projects best.

By understanding the difference between MIG (Metal Inert Gas) and MAG (Metal Active Gas) welding processes—such as their choice of shielding gas types—and considering their respective applications, one can make informed decisions about which technique will yield optimal results based on project requirements.

Forney Easy Weld 261, 140 FC-i MIG Welder, 120V, Green

$199.99 in stock

iMeshbean 10 Feet MIG Welding Gun Replacement Torch Stinger for Chicago Electric MIG Welders 94164/97503 / 36691/06098/ 36693/68885/ 93793

Weldpro Multi Function 3 tier Welding Cart. TIG, MIG, Stick or Plasma, gas bottle and accessory storage.

DEKOPRO 110/220V MMA Welder,160A ARC Welder Machine IGBT Digital Display LCD Hot Start Welder with Electrode Holder,Work Clamp, Input Power Adapter Cable and Brush

$119.99 in stock

1 used from $105.40

Lincoln Electric DynaMIG HD Professional MIG Welding Gloves | Comfort & Heat Resistance | Medium | K3806-M

Capri Tools Locking Welding Clamp, 3 Pieces

Timberland PRO Men's Pitboss 6" Steel-Toe Boot, Wheat , 9.5 D - Medium

Universal MIG Welding Cart, Rolling Welding Cart with Wheels for TIG MIG Welder, 110Lbs Capacity, Black

Hobart 770074 Welding Mig Accessory Nozzle Gel

$13.99 in stock

Goplus MIG 130 Welder Flux Core Wire Automatic Feed Welding Machine

Super Deal PRO Commercial MIG 130 AC Flux Core Wire Automatic Feed Welder Welding Machine w/Free Mask 110V

2020 Weldpro 200 Amp Inverter Multi Process Welder with Dual Voltage 220V/110V Mig/Tig/Arc Stick 3 in 1 welder/welding machine

Lincoln Electric Magnum PRO 100SG Spool Gun | for Aluminum MIG Welding | Compatible with PowerMIG Machines | 10 FT Cable | K3269-1

Weller 9400PKS 120V Dual Heat 140/100W Universal Soldering Gun Kit with 6 Second Heat Up Time and LED Lighting

$41.56 in stock

3 used from $33.58

Soldering Iron Kit Solder Gun - 110V 80W Digital Solder Iron Temperature Adjustable Auto Standy Auto Shut Down Welding Tools Soldering Kit for Electronic Production/Soldering/Desoldering

Soldering Station, 65W Tilswall Solder Station Welding Iron with Smart Temperature Control (392°F-896°F), Extra 5pcs Soldering Tips, Built-in Transformer, Ideal for School Lab, Hobby, Electronics

7pcs Triangular/Round Speed Welding Nozzle with Tacking Nozzle Push Fit 5mm Standard Weld Tip for PVC Vinyl Flooring Plastic Hot Air Welder,Weld Nozzles for Fabrication and Car Bumpers Repairing

Miller Mig Welding Gun 250Amp 15Ft Welding Gun Torch Welder Gun M-25 Welding Torch Stinger Replacement for Miller H-10, H100S2-10 fit 0.030"-0.035" Wire (250Amp 15Ft)

WeldingCity MIG Welding Gun Torch Stinger Package 150Amp 12-ft Replacement for Miller Millermatic M-150/M-15 (249040)

YESWELDER Mig Welding Gun Torch Stinger 15ft (4.5m) 250 Amp Replacement for Miller M-25 169598 fit Millermatic 212 & 252

$85.66 in stock