Welcome to our in-depth guide and review of the best laser welding machines available in 2024. We understand the importance of finding a suitable machine for your needs, so let us help you make an informed decision.

Key Takeaways:

- Laser welding machines are widely used in automotive, aerospace, jewelry, and medical equipment manufacturing industries.

- They provide precise and accurate welds with faster welding speeds and minimal distortion.

- When purchasing a laser welding machine, essential factors include power output, size and type of machine, material compatibility, and cost.

- STYLECNC is a reliable source for purchasing laser welding machines, ensuring quality and after-sales support.

- Laser welding machines utilize laser technology to create welds by interacting with a high-intensity beam and the materials.

Introduction to Laser Welding Machines

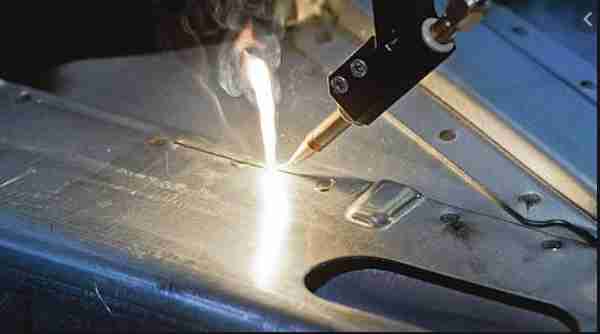

Laser welding machines are advanced automotive, aerospace, jewelry, and medical equipment manufacturing equipment to provide precise, fast, and distortion-free welds. These machines utilize laser technology, where a high-intensity beam interacts with the materials to create welds with high energy density. This allows for temperature capabilities over 10,000 degrees Celsius, ensuring solid and durable welds.

Compared to traditional welding methods, laser welding machines offer numerous advantages. They are known for their speed, as they can complete welds in a fraction of the time it takes for conventional welding. Furthermore, laser welding machines provide exceptional precision, producing accurate and high-quality welds. The minimal distortion produced by laser welding makes it ideal for applications that require intricate and delicate work.

When purchasing a laser welding machine, it is essential to consider several factors. The machine’s power output should align with the specific welding requirements and materials. The size and type of the machine are also crucial, as they determine the accessibility and maneuverability in different work environments. Material compatibility is another critical consideration, ensuring the laser welding machine suits your work materials. Lastly, cost plays a significant role, and finding a machine that fits your budget while offering the necessary features and capabilities is essential.

| Type of Laser Welding Machine | Price (2023) |

|---|---|

| Handheld | $7,800.00 (average) |

| Robot | $52,800.00 (average) |

Advantages of Laser Welding Machines

- Precise and accurate welds

- Faster welding speeds

- Minimal distortion

- High energy density

- Wide range of applications

Laser welding machines provide precise, fast, and distortion-free welds, making them indispensable in industries such as automotive, aerospace, jewelry, and medical equipment manufacturing.

STYLECNC is a reliable source for purchasing laser welding machines. As a reputable supplier, they offer a range of high-quality machines that meet industry standards. By choosing a reliable source, you can ensure your laser welding machine’s quality and after-sales support, providing you with peace of mind and long-term satisfaction.

Factors to Consider when Purchasing a Laser Welding Machine

Before investing in a laser welding machine, it’s crucial to consider factors like power output, machine size, material compatibility, and pricing to ensure you choose the best machine for your needs. Laser welding machines come in various models with different specifications, so understanding these factors will help you make an informed decision.

Firstly, power output plays a significant role in determining the welding capabilities of the machine. Higher power output generally allows for faster and deeper welds, making it suitable for heavy-duty applications. On the other hand, lower-power machines are more cost-effective and sufficient for lighter tasks. It is essential to align the power requirements with your specific welding needs.

Machine size and type should be considered based on your workspace and application requirements. Compact and portable machines are suitable for small workshops or on-site projects, while larger machines offer higher production capacities and better precision. It would be best to consider the machine’s compatibility with the materials you intend to weld, such as metals or plastics.

Lastly, pricing is a critical factor. Laser welding machines vary in cost depending on their configurations and features. Handheld machines, which are more affordable, have an average cost of around $7,800.00 in 2023, while robot types can cost around $52,800.00. Setting a budget and finding a machine that offers the best value for your investment is essential.

| Factor | Consideration |

|---|---|

| Power Output | Higher power for heavy-duty tasks, lower power for cost-effectiveness |

| Machine Size and Type | Consider workspace limitations and application requirements |

| Material Compatibility | Ensure the machine is suitable for the materials you plan to weld |

| Pricing | Set a budget and find a machine that offers the best value for your investment. |

Considering these factors, you can confidently select a laser welding machine that meets your needs. Whether you require a precision laser welding machine for metals or a more budget-friendly option, assessing power output, machine size, material compatibility, and pricing will guide you toward the right choice.

Reliable Source for Laser Welding Machine Purchase

When purchasing a laser welding machine, choose a reliable supplier or manufacturer like STYLECNC, which offers high-quality machines and excellent customer service. With their expertise and industry experience, STYLECNC ensures that each machine meets the highest performance and durability standards.

STYLECNC is a reputable supplier known for its extensive range of laser welding machines. They work closely with top manufacturers to provide customers with the latest and most advanced technology in laser welding. Whether you need a handheld laser welding machine or a large-scale industrial model, STYLECNC has a wide selection to suit your needs.

With STYLECNC, you can expect the highest quality machines and excellent customer support. Their team of experts is always ready to assist you in finding the perfect laser welding machine for your application. They provide detailed information, technical support, and guidance throughout the purchasing process to ensure your complete satisfaction.

| Laser Welding Machine Models | Price Range |

|---|---|

| Handheld Laser Welding Machine | $7,800.00 |

| Robot Laser Welding Machine | $52,800.00 |

With competitive pricing and a comprehensive warranty, STYLECNC offers excellent value for your investment. They prioritize customer satisfaction, ensuring you receive a high-quality laser welding machine that meets your requirements.

Choosing a reliable supplier or manufacturer like STYLECNC ensures you receive a top-quality laser welding machine and ongoing support and service. With their commitment to excellence, STYLECNC is the ideal partner for all your laser welding needs.

Laser Welding Machine Technology and Operation

Laser welding machines harness the power of laser technology to create welds by focusing a high-intensity beam onto the materials, resulting in precise, efficient, and versatile welding applications. These machines utilize powerful lasers that emit a concentrated light beam, which is then directed onto the workpiece. The laser beam generates heat, causing the materials to melt and fuse, creating a strong and durable weld.

One of the key advantages of laser welding machines is their high energy density, which allows for precise control over the welding process. The laser beam can reach temperatures over 10,000 degrees Celsius, ensuring accurate and consistent welds. Additionally, laser welding offers fast welding speeds and minimal distortion compared to traditional welding methods.

Laser welding machines are highly versatile and can be used on various materials, including metals, plastics, and even ceramics. They are widely employed in various industries, such as automotive, aerospace, jewelry, and medical equipment manufacturing. Laser welding machines can perform spot, butt, stitch, and sealing welding, making them suitable for miniature, precise, and heat-sensitive workpieces.

| Advantages of Laser Welding Machines |

|---|

| Precise and accurate welds |

| Faster welding speeds |

| Minimal distortion |

| Versatile applications |

When considering a laser welding machine, it is essential to consider factors such as the power output, size and type of the machine, material compatibility, and cost. Choosing a reliable source, such as STYLECNC, is recommended for purchasing laser welding machines to ensure quality and after-sales support.

Types of Laser Welding Machines

Laser welding machines can be classified into different types based on their laser source. Some common types include CO2, YAG, and fiber laser welders. Each type has its advantages and is suitable for different materials and thicknesses.

“Laser welding machines are revolutionizing the welding industry with their precision, speed, and versatility. With their high energy density and ability to work on a variety of materials, laser welders offer a superior welding solution for a wide range of applications.”

Laser welding machines provide fast, precise, and reliable welding solutions in manufacturing, automotive, aerospace, jewelry, and other industries. By understanding the technology, operation, and different types of laser welding machines, businesses can make informed decisions when choosing the suitable machine for their specific applications.

Types of Laser Welding Machines and their Suitable Applications

Laser welding machines come in various types, such as CO2, YAG, and fiber laser welders, each designed to handle different materials and thicknesses, providing optimal welding solutions for specific applications. CO2 laser welding machines are commonly used for non-metallic materials, such as plastics, textiles, and wood. They are ideal for applications that require high power and deep penetration, making them suitable for heavy-duty welding tasks.

YAG laser welding machines, on the other hand, are highly versatile and can weld a wide range of materials, including metals, ceramics, and plastics. They are known for their excellent beam quality, ideal for the precision welding of small and delicate components, such as electronics, jewelry, and medical devices.

Fiber laser welding machines are gaining popularity due to their high energy efficiency and compact size. They can weld various metals, including stainless steel, aluminum, and copper. Fiber laser welders offer high-speed welding with excellent beam quality, making them suitable for industrial applications such as automotive manufacturing, aerospace, and general metal fabrication.

Table 1: Comparison of CO2, YAG, and Fiber Laser Welding Machines

| Type of Laser Welding Machine | Materials | Application | Advantages |

|---|---|---|---|

| CO2 Laser Welding Machine | Non-metallic materials such as plastics, textiles, and wood | Heavy-duty welding tasks | High power and deep penetration |

| YAG Laser Welding Machine | Metals, ceramics, and plastics | Precision welding of small and delicate components | Excellent beam quality and versatility |

| Fiber Laser Welding Machine | Various metals, including stainless steel, aluminum, and copper | Industrial applications, automotive manufacturing, aerospace, general metal fabrication | High energy efficiency, compact size, and high-speed welding |

When choosing a laser welding machine, it is essential to consider the specific requirements of your application. Factors such as material compatibility, thickness, power output, and beam quality should all be considered. It is recommended to consult with a reputable supplier or manufacturer, like STYLECNC, to ensure that you select the suitable machine for your needs. With a suitable laser welding machine, you can achieve precise and efficient welds, enhancing the quality and productivity of your welding projects.

Industrial Uses of Laser Welding Machines

Laser welding machines find extensive applications in various industries, from manufacturing to automotive, aerospace, jewelry, biomedicine, and electronics, providing fast and precise welding solutions for specific industrial needs. These machines harness the power of laser technology to create welds with high energy density and temperature capabilities, allowing for precise and efficient joining of materials. Let’s explore some critical applications of laser welding in different industries.

1. Automotive Laser Welding

Laser welding is widely used in the automotive industry for body tailoring and parts welding. This technology offers numerous benefits, such as weight reduction, improved rigidity, enhanced collision safety, and the elimination of secondary processing. Laser welding enables automakers to achieve firm and aesthetically pleasing welds, ensuring vehicles’ overall quality and durability.

2. Aerospace Laser Welding

Aerospace manufacturers use laser welding to split large aircraft skins and long trusses. With its high precision and efficiency, laser welding ensures the production of high-quality welds in critical aerospace components. Combining dissimilar metals and handling complex geometries makes Laser welding a valuable technology in aircraft manufacturing, contributing to lightweight and fuel-efficient aircraft design.

3. Jewelry Laser Welding

In the jewelry industry, laser welding has revolutionized how intricate repairs, spot welding, and inlays are performed. Laser welders offer jewelers the precision and control required for working with delicate materials like gold and silver. The non-contact nature of laser welding minimizes the risk of damage to surrounding areas, making it an ideal choice for intricate jewelry work. Jewelers can achieve seamless and durable welds, ensuring the longevity and beauty of their creations.

As laser welding technology advances, its applications will benefit many industries. By leveraging laser welding machines’ speed, precision, and versatility, businesses can achieve efficient production, high-quality welds, and improved productivity in their respective industries.

| Laser Welding Machine | Manufacturer | Price (2023) |

|---|---|---|

| LightWELD XR | IPG Photonics | $7,800.00 |

| HW-D | Han’s Laser Corporation | $9,500.00 |

| Baison laser welder | Baison | $6,200.00 |

| HW-1500 | HS Laser | $10,800.00 |

| PhotonWeld A1600 | Photon Laser | $12,500.00 |

Laser Welding in the Automobile Industry

Laser welding plays a significant role in the automobile industry, enabling body tailor and parts welding, resulting in lightweight construction, improved rigidity, enhanced collision safety, and streamlined production processes. Using laser technology, automotive manufacturers can achieve precise and accurate welds, ensuring vehicles’ structural integrity and longevity.

One of the key advantages of laser welding in the automotive industry is its ability to reduce the weight of vehicle bodies. This weight reduction contributes to improved fuel efficiency and overall performance. Laser welding enhances rigidity, increasing the vehicle’s resistance to bending and torsional forces, leading to better handling and stability on the road.

Furthermore, laser welding eliminates the need for secondary processing, such as grinding or polishing, as the process produces minimal distortion. This streamlined production process saves time and reduces costs for automakers. Laser welding machines can perform spot, butt, stitch, and sealing welding, making them suitable for large-scale production and intricate, precise work on heat-sensitive materials.

| Laser Welding Benefits in the Automobile Industry |

|---|

| Lightweight construction |

| Improved rigidity |

| Enhanced collision safety |

| Streamlined production processes |

Laser welding machines have revolutionized the automobile industry, allowing manufacturers to produce lighter, stronger, and safer vehicles. By leveraging the precision and efficiency of laser welding, automakers can meet the demands of a rapidly evolving industry while maintaining high-quality standards.

Laser Welding in Aircraft Manufacturing

Laser welding is widely employed in aircraft manufacturing for splicing large aircraft skins and long trusses, delivering high-quality welds and efficient production processes. The aerospace industry relies on laser welding machines to ensure aircraft components’ structural integrity and durability. Using laser technology, precise and controlled heat is applied to the materials, resulting in solid and reliable welds.

One of the key advantages of laser welding in aircraft manufacturing is the ability to join dissimilar materials without compromising strength or performance. This allows for combining lightweight materials, such as aluminum and composite materials, reducing the aircraft’s overall weight and improving fuel efficiency. Additionally, laser welding enables the production of complex shapes and intricate designs, enhancing the aerodynamic performance of the aircraft.

| Advantages of Laser Welding in Aircraft Manufacturing |

|---|

| High-quality welds with minimal distortion |

| Precision and accuracy in joining large skins and trusses |

| Ability to join dissimilar materials |

| Non-contact process, reducing the risk of damage to delicate components |

| Efficient and time-saving production processes |

Furthermore, laser welding offers high productivity and cost savings in aircraft manufacturing. The non-contact nature of the process eliminates the need for additional clamping or fixturing, reducing production time and costs. Additionally, the precision and accuracy of laser welding result in minimal rework and scrap materials, further optimizing the manufacturing process.

In conclusion, laser welding is critical in aircraft manufacturing by providing high-quality welds, efficient production processes, and the ability to join dissimilar materials. The aerospace industry continues to rely on laser welding machines for their precision, speed, and cost-effectiveness, ensuring the safety and performance of modern aircraft.

Laser Welding in the Jewelry Industry

In the jewelry industry, laser welding is widely used for repairing holes, spot welding, and inlays in gold and silver jewelry, offering precise and versatile welding solutions for intricate designs. Laser welding machines allow jewelry manufacturers to create solid and seamless connections between delicate pieces, ensuring high-quality craftsmanship.

One of the key advantages of laser welding in the jewelry industry is its ability to create heat-affected zones that are significantly smaller compared to traditional welding methods. This enables jewelers to work on intricate designs without damaging the surrounding areas or causing any discoloration. The laser beam’s high energy density allows for pinpoint accuracy and control, resulting in clean and aesthetically pleasing welds.

Moreover, laser welding machines offer quick and efficient operations, reducing the time required to complete jewelry repairs and production processes. This allows jewelers to meet tight deadlines while maintaining the highest quality standards. Additionally, laser welding minimizes the need for additional soldering and polishing, eliminating the risk of damaging delicate gemstones or precious metals.

Benefits of Laser Welding in the Jewelry Industry:

- Precision: Laser welding provides precise control over the welding process, ensuring accurate connections without damaging the surrounding areas.

- Efficiency: Laser welding machines offer fast and efficient operations, increasing productivity and shortening production cycles.

- Quality: Laser welding creates durable and aesthetically pleasing welds, preserving the integrity and appearance of the jewelry.

- Versatility: Laser welding can be used for various jewelry repairs and production processes, accommodating various designs and materials.

Overall, laser welding has revolutionized the way jewelry is repaired and manufactured. Its ability to provide precise and versatile welding solutions has made it an indispensable tool for jewelers looking to create intricate and high-quality pieces.

| Top Laser Welding Machine Options in 2023 | Manufacturer | Price |

|---|---|---|

| LightWELD XR | IPG Photonics | $10,500 |

| HW-D | Han’s Laser Corporation | $12,800 |

| Baison laser welder | Baison | $8,900 |

| HW-1500 | HS Laser | $7,200 |

| PhotonWeld A1600 | PhotonWeld | $9,300 |

Top Laser Welding Machine Options

If you’re looking for the best laser welding machine in 2023, consider options like the LightWELD XR, HW-D, Baison laser welder, HW-1500, and PhotonWeld A1600, each offering unique features and benefits for different welding requirements.

Laser welding machines have become essential in various industries, providing precise and accurate welds with faster welding speeds and minimal distortion. Let’s take a closer look at these top laser welding machine options:

LightWELD XR

The LightWELD XR from IPG Photonics is a high-performance laser welding machine suitable for various applications. Its advanced fiber laser technology offers exceptional beam quality, allowing precise and efficient welding. The LightWELD XR is known for its excellent stability, energy efficiency, and user-friendly interface. It is an ideal choice for industries that require high-quality welds, such as automotive, aerospace, and medical equipment manufacturing.

HW-D

The HW-D laser welder from Han’s Laser Corporation is a versatile machine designed for manual and automated welding tasks. It offers various power output options, allowing users to select the most suitable level for their welding needs. The HW-D features advanced control systems, an ergonomic design, and reliable performance. It is widely used in precision welding industries, such as jewelry and microelectronics assembly.

Baison laser welder

The Baison laser welder is a compact, portable machine that combines performance and affordability. It is equipped with a fiber laser source, which delivers excellent beam quality and stability. The Baison laser welder suits various materials, including stainless steel, aluminum, and titanium. Its user-friendly interface and intuitive controls make it an ideal choice for small workshops or businesses looking to upgrade their welding capabilities.

HW-1500

The HW-1500 from HS Laser is a robust, powerful laser welding machine designed for industrial applications. It offers high-speed welding with exceptional precision, making it suitable for heavy-duty welding tasks. The HW-1500 features a user-friendly interface, automatic parameter adjustment, and real-time monitoring, ensuring optimal welding results. It is widely used in automotive manufacturing, construction, and shipbuilding industries.

PhotonWeld A1600

The PhotonWeld A1600 is a state-of-the-art laser welding machine known for its advanced technology and superior performance. It utilizes a fiber laser source with high energy density, enabling precise and efficient welding.

The PhotonWeld A1600 offers various welding modes and adjustable parameters, allowing users to customize their welding process according to their specific requirements. It is widely used in automotive, aerospace, and electronics industries for applications that demand high-quality and high-speed welding.

| Machine | Main Features | Industry Applications | Price (USD) |

|---|---|---|---|

| LightWELD XR | High-performance fiber laser technology, excellent stability | Automotive, aerospace, medical equipment | Variable |

| HW-D | Manual and automated welding, wide power output range | Jewelry making, microelectronics | Variable |

| Baison laser welder | Compact, portable, affordable | Various industries | Variable |

| HW-1500 | Robust, high-speed welding, user-friendly interface | Automotive, construction, shipbuilding | Variable |

| PhotonWeld A1600 | Advanced technology, adjustable parameters | Automotive, aerospace, electronics | Variable |

Laser welding is a process that has been gaining popularity in the manufacturing industry over the last decade as it provides an efficient and reliable way to join two or more materials together.

With so many new models of laser welding machines on the market, it can be hard to know which is best for your specific application.

So let’s get started! We’ve put together this guide to help you find the best laser welding machine for 2023. We’ll cover everything from what features to look for when shopping for a laser welding machine to which manufacturers are leading the pack regarding quality and performance.

You are on the right page to look for information about laser welders.

This article will explain laser welding machines’ applications and help you find your ideal laser welding machine. Let us begin!

What is Laser Welding?

Laser welding is a type of welding that uses a laser to heat the material being joined. The laser beam provides a concentrated heat source, allowing a very high heating rate. This high heating rate helps to create a weld that is strong and has minimal distortion. There are two main types of laser welding: gas-assisted and solid-state.

Gas-assisted laser welding uses a mixture of gases to assist in welding. The most common gas used is helium. Helium allows for a very high heating rate, which helps to create a strong weld. However, using helium can also cause the welded material to become brittle.

Solid-state laser welding does not use any gases to assist in the welding process. Instead, it relies on light absorption by the material being welded. This absorption creates heat, which is used for welding the material together. Solid-state laser welding is often used for thinner materials, as it can provide a more precise weld than gas-assisted laser welding.

The Best Laser Welders of 2024

Hukoer – Laser electric welding machine

It is a safe and stable welder that can be used for jewelry and dental welding.

As you can see in the image, it has five buttons that correspond to its five specific programs according to the material to be welded, these being the materials with which you can work: Gold (Au), Cobalt Chrome (Co-Cr), welding hybrid (Hybrid), Titanium (Titan) and orthodontics (Ortho).

It does not take much space to work with this machine, and if you are looking for a cheap laser welder, this can be an excellent choice.

In this video, although I don’t know the language in which it is and cannot be understood, this welder model is taught how to use it, and it can help you get an idea if you are considering acquiring it.

Ding Xing- 220V electric laser welder

With this laser welder, you can weld different materials, such as precious metals, copper, silver, gold, iron, or steel, but it is not used to weld aluminum.

You must always work with tiny materials that do not exceed 1.2 mm.

It has a power supply of 220 v and a power of 400 W, with a weight of about 6 kg.

The welder includes a foot pedal, a cable, a clamp, a tungsten needle, and a handle welder.

It has five stars on Amazon, a cheap and recommended laser welding machine.

Laser welders on offer at Amazon:

Read Next – Best Welding Helmets Auto Darkening Buying Guide

Laser welding: what is a laser welding machine for?

Welding and laser welding applications are ideal for the jewelry and orthodontic sector.

Since laser technology allows us to achieve an impossible accuracy with other technologies, you can see more welders on Amazon if they don’t convince you.

Therefore, it is the most appropriate technique for sensitive and small areas.

It is not only used in jewelry since the diversity in the Laser’s employability does not have any other type of welding: you can quickly create fine welding points of 1 mm in diameter and deep welding cords.

With a minimum deformation, very fine seam geometries can be created with a tremendous depth-width relationship.

It also manufactures high-speed trains, pacemakers, and airbag housings.

Due to operating with a much more complex system, these welders are much more sophisticated than all that can be seen on the page, so they have a much higher price.

Read Next – Laser Welding Stainless Steel

The Best Laser Welding Machine of 2024

How does laser welding work?

Laser welding uses the thermal effect of the laser beam’s impact, which produces the fusion of the material.

The laser beam melts the metal as it moves, and in this way, the weld bead is created, minimizing the material properties.

One of these welders’ significant advantages is leaving a smooth, rounded weld bead, eliminating the review process.

Advantages of laser welding

As we mentioned earlier, laser welding machines, although they are more expensive, have some advantages:

- This system does not need the contribution of material.

- Provides thin and deep cords.

- It practically does not cause deformation in the area.

- It gives the possibility of high-precision joints.

- I solder very fast.

Read Next – Welding Shoe Cover

For suitable welding, you need a high-quality arc power source that will keep it stable even with unsuitable current parameters in the network. This is a must-have machine for home and professional use, and for such purposes, you should buy only one of the best laser welding machines. For this, you don’t have to chase after the most expensive welding machine in the world, but you still need to take a closer look at our rating of the best laser welding machines with a detailed analysis. So, let’s hurry to study these devices!

Read Next – What is the Best Tig Welding Machine Lincoln

5 Top And Best Laser WeldingMachinese:

To help you choose the best laser welding machine, we considered its efficiency, versatility, functionality, ease of use, safety, and other parameters.

So, see these best laser welding machines here…

1500W JPT Handheld Fiber Laser Welding Machine:

Opens our rating of inverters MMA 1500W JPT Handheld Fiber Laser Welding Machine. Stick electrodes and shielded gas welding are supported, and the maximum current output by the inverter converter in both modes is 200 amperes. In the Pulse mode, the welder can adjust both the frequency, the balance, and the lower level of the ripple current; in the TIG mode, as you already understood, welding is available on both AC and DC.

At the same time, adjusting the starting current separately from the working draft, adjusting the balance in the TIG AC mode, and switching between two-stroke and four-stroke modes is possible. In the latter, the crater-filling setting is also available.

In a word, this is an excellent welding machine in terms of versatility, capable of operating in various conditions – from jewelry welding of thin-walled parts with Argon to cutting metal with an electrode.

JPT 1500W Laser welding machine Handheld laser welder machine Fiber laser welder machine for Metal Laser welder with Auto Wire Feeder

1500W JPT HandHeld Fiber Laser Welding Machine Laser Welder with Auto Wire Feeder

JPT 2000W Laser Welding Machine:

JPT 2000W Laser Welding Machine is one of the best Laser Welding Machines. The Torus brand is well-known among professional welders. The inverters of this company may not be the most potent MMA inverters, but they survive the warranty period without any problems, even with the most challenging operation.

The MMA/TIG-inverter “200s Super” will allow the owner to work at a current of up to 200 A at a duty cycle of 100 – which means the possibility of full-fledged long-term work with electrodes up to 5 mm in diameter.

The high quality of the welds created by the device. The merit of this is in the microprocessor circuit for forming the current curve – this ensures its optimal shape and the stability of the characteristics with a substantial voltage drop.

The inverter will be equally convenient for a welder with many years of experience and a beginner – it is straightforward to start and hold the arc on it and in the TIG mode, like when welding with a stick electrode.

The minimum current is 20A, making it possible to use the 200s Super inverter for argon welding of the thinnest parts.

JPT 2000W Laser welding machine Handheld laser welder machine Fiber laser welder machine for Metal Laser welder with Auto Wire Feeder

2000W Laser Welding Machine JPT Fiber Laser Welder Machine with Handheld Welding Gun Built-in Water Cooling 7-meter Optic Fiber Cable

Spectra Precision GL622N Dual-Slope Grade Laser Level Kit:

Our rating of professional welding inverters continues with the Spectra Precision GL622N Dual-Slope Grade Laser Level Kit model.

This inverter in MMA and TIG modes allows welding current up to 200 A, while PV reaches 80%. At currents less than 160 A, an efficient cooling system allows the inverter to be used without obligatory cooling pauses. This is one of the best Laser Welding Machines.

When working with the Tech Arc 205 B device, it should be considered that the power consumed in the MMA mode reaches 9 kW, and massive power supply voltage drops are possible.

However, thanks to the built-in digital indicator of the welding current, they can be compensated to a certain extent – on devices where the wind is set on a scale near the regulator, the current must be adjusted to the desired value “by eye.”

If you wonder which professional welding machine is better, we can confidently say Spectra Precision GL622N Dual-Slope Grade, Laser Level Kit!

Spectra Precision GL622N Dual-Slope Grade Laser Level Kit with HL760 Laser Meter, C70 Rod Clamp, RC602N Remote Control, 10 Ah NiMH Batteries, Charger, Use for Tiling, Construction, Flooring

1 used from $1,976.64

Spectra Precision GL612N Single-Slope Grade Laser with HL760 Digital Readout Receiver, C70 Rod Clamp, RC602 Remote Control, 10 Ah NiMH Batteries, Charger, and hard carrying case

Read Next – Best MIG & Stick Welding Gloves 2024

ZAC 1500W JPT Laser Welder Handheld:

This is mainly for you if you are not chasing the latest welding machine. It contains almost the maximum possible versatility: it can work as a semiautomatic device and cook in MMA and TIG modes. Of course, with a maximum current of 160 A and low PV, with all the desire, it cannot be classified as professional, but its capabilities will be enough in a personal workshop.

Considering that arc force, anti-sticking, and “hot start” are introduced into the device’s design, it is difficult to demand anything else for the MMA mode if you work with 2-3 mm diameter electrodes. This is one of the best Laser Welding Machines.

Need to weld thin iron? Well, put a spool of wire and connect the burner. The device can operate in a two-stroke or four-stroke scheme in MIG mode. Although this is not such a severe advantage – it would be better if the manufacturer expanded the TIG mode settings.

ZAC 1500W JPT Laser Welder Handheld Fiber Laser Spot Welding Machine with Auto Wire Feeder for Metal Steel Welding

1500W JPT Fiber Laser Welding Machine 1.5KW Handheld Laser Welder Machine for Metal Portable Welding Gun with Auto Wire Feeder for Stainless Steel Carbon Welding

Read Next – Handheld Laser Welder

Jewelry Spot Welding Machine Pulse Sparkle Spot Welder:

Our professional inverter welding machines review includes the Jewelry Spot Welding Machine Pulse Sparkle Spot Welder model. The ultra-modern design will give the professional precisely what he needs – the reliability and accuracy of forming the current-voltage characteristic of the welding current in the MMA and TIG modes. This is one of the best Laser Welding Machines.

The maximum welding current is 160A, but continuous operation is possible at a current not exceeding 100A.

Therefore, this inverter is most suitable for working with sufficiently thin metal that does not require deep penetration at a high current. Among the advantages of the device is the ability to work with solid voltage drops – the performance declared by the manufacturer at 140V in the socket is ideally confirmed in practice.

A “soft” arc is easily ignited and burns without strong metal spatter. The automatic control of the fan in the inverter by a signal from the temperature sensor significantly reduces the amount of dust sucked into the case, making cleaning the radiators of the output stage less frequent.

Jewelry Spot Welder, Pulse Sparkle Spot Welder 110V 80A Portable Spot Welding Machine with Foot Pedal for Jewelry Gold Silver Platinum

80A 110V Jewelry Spot Welder Pulse Sparkle Spot Welder Portable Spot Welding Machine with Handle Tool for Gold Silver Platinum

Is laser welding better than MIG welding?

There are many factors to consider when deciding if laser welding is better than MIG welding for your specific application.

Some advantages of laser welding over MIG welding include the following:

- Laser welds are more precise and can be performed on thinner materials.

- Laser welds have a higher strength and can be less susceptible to cracking.

- Laser welds are less likely to distort the material being welded.

- Laser welds can be performed in a shorter time frame.

MIG welding also has its advantages, which include the following:

- MIG welding is typically faster than laser welding for larger projects.

- MIG welding can be used in a broader range of materials, including aluminum and stainless steel.

- MIG welders are typically less expensive than laser welders.

The best way to decide if laser or MIG welding suits your project is to consult an expert who can assess your needs and requirements.

Does laser welding need Argon?

Laser welding does not require Argon but can be used if desired. Argon is an inert gas that can help to protect the weld area from oxidation.

Will laser welding replace TIG?

Laser welding is a type of welding that uses a laser to heat the material being joined.

The heat from the Laser melts the materials, which are then drawn together by the pressure of the laser beam. This process creates a strong weld that is less likely to crack or break than a traditional weld.

While laser welding has many advantages over traditional methods like TIG welding, it has disadvantages. Laser welding is more expensive than TIG welding and requires special equipment that may not be available in all areas.

Additionally, laser welding can be challenging to control, making it more difficult to produce consistent results.

How thick of metal can a laser welder weld?

The thickness of metal that a laser welder can weld depends on the type of Laser used. For example, a CO2 laser can weld metal up to 1/8 inch thick, while a fiber laser can weld metal up to 1/2 inch thick.

Can a laser welder weld aluminum?

Yes, a laser welder can weld aluminum. There are a few things to remember when welding aluminum with a laser welder.

First, the aluminum must be clean and free of oxides. Second, the welder must have the proper settings for welding aluminum. Third, the welder must use the proper technique when welding aluminum.

Can you use a laser welder on steel?

Yes, you can use a laser welder on steel. There are a few things to remember when welding steel with a laser welder. First, the laser beam will not penetrate as far into the steel as other materials.

This means you need to be careful not to overheat the area around the weld. Second, because the laser beam is so concentrated, it can cause the steel to warp if you’re not careful.

Finally, you must use a different filler material when welding steel with a laser welder. Steel welds require a higher melting point filler material, such as tungsten or nickel.

Laser Welding Machine FAQs

What are the best laser welding machines on the market?

Many different types and models of laser welding machines are available, so choosing the best one for your needs can be challenging.

Some factors to consider when choosing a laser welding machine include the type of materials you will be welding, the thickness of the materials, and the speed at which you need to weld.

What are the benefits of using a laser welding machine?

Laser welding machines offer many benefits over traditional welding methods, such as higher speed, greater accuracy, and less heat distortion.

Laser welds also have a smaller heat-affected zone than other welds, making them ideal for delicate materials or areas requiring precision.

What should I look for when purchasing a laser welding machine?

When purchasing a laser welding machine, you should consider its power output, wavelength, duty cycle, beam quality, and focal spot size. It would be best if you also decided whether you need a portable or desktop model.

Read Next – Best Welding Helmets Under $50

What industries use laser welding machines?

Laser welding machines are widely used in various industries, such as automotive, aerospace, jewelry, and medical equipment manufacturing.

What are the benefits of laser welding machines?

Laser welding machines provide precise and accurate welds with faster welding speeds and minimal distortion.

What factors should I consider when purchasing a laser welding machine?

Essential factors to consider when purchasing a laser welding machine include the power output, size and type of the machine, material compatibility, and cost.

Where can I find a reliable source for purchasing laser welders?

STYLECNC is a reliable source for purchasing laser welders.

How do laser welding machines work?

Laser welding machines utilize laser technology to create welds by interacting with a high-intensity beam and the materials.

What is the average cost of a laser welding machine?

The average cost for handheld types is around $7,800.00, and for robot types, it is around $52,800.00 in 2023.

What types of laser welding machines are available?

Laser welding machines can be classified into different types, including CO2, YAG, and fiber laser welders, suitable for different materials and thicknesses.

What are the uses of laser welding machines?

Laser welding machines have many uses, including manufacturing, automotive, aerospace, jewelry, biomedicine, and electronics.

What types of welding can laser welders perform?

Laser welders can perform spot, butt, stitch, and sealing welding, making them suitable for miniature, precise, and heat-sensitive workpieces.

How is laser welding used in the automobile industry?

Laser welding is widely utilized in the automobile industry for body tailor and parts welding, reducing weight, improving rigidity and collision safety, and eliminating the need for secondary processing.

How is laser welding used in aircraft manufacturing?

Laser welding is used in aircraft manufacturing for splicing large aircraft skins and long trusses, resulting in high-quality and efficient production.

How is laser welding used in the jewelry industry?

Laser welding is used in the jewelry industry to repair holes, spot welding, and inlays in gold and silver jewelry.

What are some top laser welding machine options?

Some top laser welding machine options include the LightWELD XR from IPG Photonics, the HW-D from Han’s Laser Corporation, the Baison laser welder, the HW-1500 from HS Laser, and the PhotonWeld A1600.

Conclusion

In conclusion, choosing the best laser welding machine requires careful consideration of factors like power output, machine type, material compatibility, and pricing, helping you find the perfect solution for your specific welding needs.

Laser welding machines are widely used in automotive, aerospace, jewelry, and medical equipment manufacturing industries. They offer precise and accurate welds with faster welding speeds and minimal distortion, making them a preferred choice for various applications.

When purchasing a laser welding machine, it is essential to evaluate the power output, size, and type of the machine and its compatibility with different materials. Additionally, considering the cost and budget is crucial to make an informed decision.

STYLECNC is a reliable source for purchasing laser welding machines, offering various options to suit different requirements. They provide quality machines with comprehensive after-sales support to ensure customer satisfaction.

Laser welding machines utilize laser technology to create welds by focusing a high-intensity beam on the materials. Their high energy density can reach temperatures over 10,000 degrees Celsius, enabling efficient and precise welding.

Laser welding machines can be classified into different types, including CO2, YAG, and fiber laser welders, each offering distinct advantages and suitability for different materials and thicknesses. This allows users to choose the suitable machine for their specific applications.

These versatile machines find applications across various industries, including manufacturing, automotive, aerospace, jewelry, biomedicine, and electronics. They can perform spot, butt, stitch, and sealing welding, making them ideal for miniature, precise, and heat-sensitive workpieces.

Laser welding is widely used in the automobile industry for body tailors and parts welding. It reduces the body’s weight, improves rigidity and collision safety, and eliminates the need for secondary processing. Similarly, laser welding is utilized in aircraft manufacturing for splicing large aircraft skins and long trusses, resulting in high-quality and efficient production.

Laser welding also plays a crucial role in the jewelry industry, allowing for the repair of holes, spot welding, and inlays in gold and silver jewelry. The precision and versatility of laser welding make it an invaluable tool for intricate jewelry work.

There are several top laser welding machine options available in 2023, including the LightWELD XR from IPG Photonics, the HW-D from Han’s Laser Corporation, the Baison laser welder, the HW-1500 from HS Laser, and the PhotonWeld A1600. These machines have unique features and benefits, catering to different user requirements.

By carefully considering the abovementioned factors and exploring the options, you can choose the best laser welding machine that fits your needs and budget. Whether you are in the automotive, aerospace, jewelry, or any other industry, laser welding machines offer fast, precise, and versatile solutions to meet your welding requirements.

Investing in a laser welding machine is a step towards enhancing your productivity and achieving high-quality welds. So, take your time, do thorough research, and make an informed decision to benefit your business in the long run.

Jewelry laser welding machine Spot Welder Gold Silver with Handle tool 110V 400W

Forney Easy Weld 261, 140 FC-i MIG Welder, 120V, Green

$199.99 in stock

2 used from $182.27

Forney Easy Weld 298 Arc Welder 100ST, 120-Volt, 90-Amp,Green

$155.40 in stock

4 used from $144.28

Lotos CT520D 50 AMP Air Plasma Cutter, 200 AMP Tig and Stick/MMA/ARC Welder 3 in 1 Combo Welding Machine, ½ Inch Clean Cut, Brown

$339.98 in stock

2020 Weldpro 200 Amp Inverter Multi Process Welder with Dual Voltage 220V/110V Mig/Tig/Arc Stick 3 in 1 welder/welding machine

MIG155GSV 155 AMP INVERTER MIG/STICK ARC WELDER WITH DUAL VOLTAGE 220V/110V welding machine

Lotos LTPDC2000D Non-Touch Pilot Arc Plasma Cutter Tig Welder and Stick Welder 3 in 1 Combo Welding Machine,½ Inch Clean Cut,Brown

$449.98 in stock

North Slope Chillers NSC1000-LT-110/1 Deep Freeze 1-Ton Industrial Chiller, 12,000 BTU's/hr, Ideal for Lasers, Engravers, Machines, Welding Equipment, Fermentation & Process Cooling

JPT 1500W Laser welding machine Handheld laser welder machine Fiber laser welder machine for Metal Laser welder with Auto Wire Feeder

1500W JPT HandHeld Fiber Laser Welding Machine Laser Welder with Auto Wire Feeder

JPT 2000W Laser welding machine Handheld laser welder machine Fiber laser welder machine for Metal Laser welder with Auto Wire Feeder

2000W Laser Welding Machine JPT Fiber Laser Welder Machine with Handheld Welding Gun Built-in Water Cooling 7-meter Optic Fiber Cable

Spectra Precision GL622N Dual-Slope Grade Laser Level Kit with HL760 Laser Meter, C70 Rod Clamp, RC602N Remote Control, 10 Ah NiMH Batteries, Charger, Use for Tiling, Construction, Flooring

1 used from $1,976.64

Spectra Precision GL612N Single-Slope Grade Laser with HL760 Digital Readout Receiver, C70 Rod Clamp, RC602 Remote Control, 10 Ah NiMH Batteries, Charger, and hard carrying case

ZAC 1500W JPT Laser Welder Handheld Fiber Laser Spot Welding Machine with Auto Wire Feeder for Metal Steel Welding

1500W JPT Fiber Laser Welding Machine 1.5KW Handheld Laser Welder Machine for Metal Portable Welding Gun with Auto Wire Feeder for Stainless Steel Carbon Welding

Jewelry Spot Welder, Pulse Sparkle Spot Welder 110V 80A Portable Spot Welding Machine with Foot Pedal for Jewelry Gold Silver Platinum

80A 110V Jewelry Spot Welder Pulse Sparkle Spot Welder Portable Spot Welding Machine with Handle Tool for Gold Silver Platinum

Q: What is a handheld laser welding machine?

A: A handheld laser welding machine is a welding device that uses a laser beam to join two or more pieces of metal together. It is portable and allows the operator to control the welding process manually.

Q: How does handheld laser welding differ from traditional welding methods?

A: Handheld laser welding differs from traditional welding methods because it uses a focused laser beam instead of an electric arc or flame to melt the metal. This results in a faster welding process and higher precision.

Q: What are the advantages of using a handheld laser welding machine?

A: There are several advantages of using a handheld laser welding machine. These include faster welding speed, higher precision, lower heat input, and the ability to weld a wide range of materials.

Q: How does a handheld laser welding machine work?

A: A handheld laser welding machine uses a laser source to generate a high-powered laser beam. This beam is then focused using a lens onto the workpiece. The laser beam melts the metal, allowing it to bond together.

Q: What are the applications of handheld laser welding?

A: Handheld laser welding is used in various applications, including fabrication, seam welding, and repairing thin materials. It is also commonly used in industries such as automotive, aerospace, and jewelry making.

Q: Can a handheld laser welding machine be used for other purposes besides welding?

A: A handheld laser welding machine can also be used for other purposes, such as laser cutting and cleaning. These machines are versatile and can perform multiple tasks.

Q: Is handheld laser welding easy to learn?

A: Handheld laser welding is relatively easier to learn than other welding techniques, such as MIG or TIG welding. With proper training and practice, operators can quickly become proficient in using a handheld laser welding machine.

Q: What factors should be considered when choosing a handheld laser welding machine?

A: When choosing a handheld laser welding machine, factors such as laser power, welding speed, welding parameters, and the range of materials it can weld should be considered. It is also essential to consider the reputation and reliability of the manufacturer.

Q: Can a handheld laser welding machine be used for small and large welding operations?

A: A handheld laser welding machine can handle small and large welding operations. The welding speed and power settings can be adjusted to accommodate different workpiece sizes and thicknesses.

Q: What is the difference between a handheld laser welding machine and a traditional welding system?

A: The main difference between a handheld laser welding machine and a traditional welding system is the technique used. Handheld laser welding machines use a laser beam, while traditional welding systems use an electric arc or flame.