Welding light metals such as aluminum represent a challenge compared to welding steel alloys.

And welding aluminum requires excellent precision to achieve a solid bond.

But what kind of welding will allow us this? If you do not know the types of welding, the difference between them, and the advantages and disadvantages, visit our article dedicated to the different types of welding.

Read Next – LOTOS MIG140 Welding Machine

But do not worry because this article will explain everything you need to know to learn to weld aluminum.

Also, we show the different methods used for welding aluminum, and the choice will depend on the particular needs of your project.

Let us begin!

Before We Start

It is best to go step by step, so first, we will explain what you should know before you start welding.

Thus, you can better understand the whole process and choose your method.

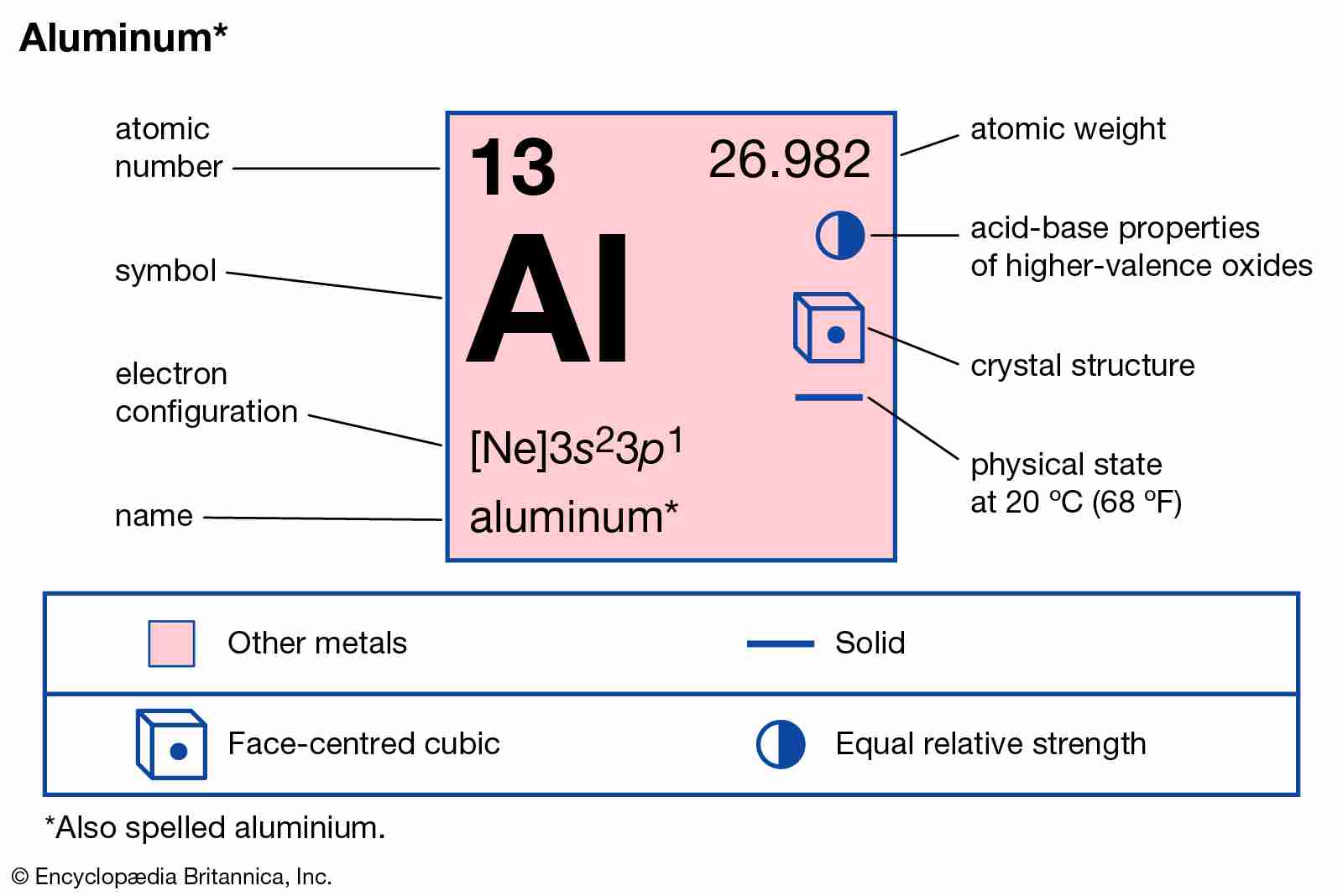

What is aluminum?

Aluminum is a light and thin metal and is one of the most used materials in welding.

Despite being light (the density of aluminum is one-third of steel), it is solid and resistant, making it popular.

It has a shallow melting point of about 660 ° C and is a conducive electricity and heat element.

Pure aluminum is widely used in electrical applications since its electrical conductivity is superior to alloys.

It is a very malleable metal and has a meager mechanical resistance.

Therefore, it is usually alloyed with different metals to harden and improve mechanical characteristics. And in this way, the alloys have better mechanical strength than pure aluminum.

SUNGOLDPOWER MIG 150A Welder Flux Core Wire Automatic Feed Welding AC Welder Gasless Machine Free Mask NO Gas

Lincoln Electric Weld Pak 140 HD Wire-Feed Welder K2514-1

Why is aluminum so difficult to weld?

The aluminum must be welded at a low temperature with a lower melting point and a very high conductivity. Burns will be created if this is not done, boring the metal.

It is also a reasonably reactive material, which causes it to form an oxide layer when exposed.

The result of this quality is usually porous welds, which is a problem.

To avoid this, you have to clean the aluminum well before welding (we will explain later) and work very quickly since, in a few minutes, it usually comes out again.

Read Next – Timberland PRO 40000 Review – Met Guard 6″ Steel Toe Boot

Aluminum Alloys

As mentioned, aluminum is alloyed with different metals to achieve more potent and durable metals.

Typically, these alloys are created with copper (Cu), Magnesium (Mg), Silicon (Si), and Zinc (Zn). To this, other metals are added in small quantities, such as Chrome (Cr), Iron (Fe), Nickel (Ni), and Titanium (Ti).

Thus, there are many aluminum alloys, all with characteristics superior to pure aluminum.

These alloys can be obtained by different techniques and molding or processes that lead to deformation, such as lamination and forging.

Classification of aluminum alloys

As mentioned, there are many types of aluminum alloys, but in this section, we will only consider aluminum alloys for forging since these are the ones used for welding.

Regarding the classification, we can distinguish two different categories. The first is vocabulary and typing, according to UNE 38-300. According to the Aluminium Association (AA), the second is the vocabulary, also known as the American classification.

According to UNE 38-300, aluminum and aluminum alloys for forging constitute the L-3XXX series.

This series is classified into different groups according to the main alloy elements.

And according to the Aluminium Association classification, each alloy is given a four-digit number, and the first is the one that shows the primary alloys.

| Alloy | UNE 38-300 | Aluminium Association |

| Aluminum (minimum purity: 99.00%) | Group L-30XX | 1XXX |

| Aluminium-Copper Alloys (Al-Cu) | Group L-31XX | 2XXX |

| Aluminium-Magnesium Alloys (Al-Mg) | Group L-33XX | 5XXX |

| Aluminum-magnesium-silicon Alloys (Al-Mg-Si) | Group L-34XX | 6XXX |

| Aluminum-Silicon Alloys (Al-Si) | Group L-35XX | 4XXX |

| Various alloys | Group L-36XX | 8XXX |

| Aluminium-Zinc Alloys (Al-Zn) | Group L-37XX | 7XXX |

| Aluminium-Manganese Alloys (Al-Mn) | Group L-38XX | 3XXX |

| Aluminium-Tin Alloys (Al-Sn) | Group L-39XX | – |

Characteristics and weldability of alloys

Once we have seen what the forging alloys are, we will see what the characteristics of each of them and the weldability of each of them are.

We can also distinguish two different groups regarding weldability among all these alloys.

And we can distinguish between bondable alloys (heat-treatable alloys) and non-bondable, these being non-heat-treatable alloys.

The heat treatment known as the bonus is heating the material to 500 ° C to cool it quickly. According to the alloy, maturation will be carried out, both natural and artificial.

The first is to keep it at room temperature, while the second is about 200 ° C.

When this treatment is performed on the bondable alloys, their hardness and mechanical strength increase, but non-bonuses do not change their properties with treatment.

Next, we will show which alloys are non-bondable since alloys of this type are weldable.

As for bonus alloys, welding is not recommended for many, although some can be welded. Let’s go there!

Aluminum Alloys

This is the L-30XX Group according to the UNE and 1XXX according to AA.

These alloys, having a minimum purity of% 99, are almost pure Aluminium.

And as we have said before, pure Aluminium is mainly used in electrical applications.

These types of alloys are non-bondable, being weldable for them.

The essential weldable alloy of this Group by the TIG and MIG processes is the L-3001 (UNE) / 1100 (AA) alloy. However, this alloy is also weldable by other types of welding, such as point resistance or seam, with solid or soft welding.

Aluminum and Copper Alloys

This is the L-31XX Group of the UNE nomenclature and 2XXX of the AA. Typically, these alloys are made of copper and coated with Aluminium.

They are solid materials but not very resistant to corrosion. It is usually used mainly in the manufacture of airplanes.

These are bonus alloys, so welding is not recommended for most welding.

However, the L-3191/2219 alloy can be welded by TIG and MIG by resistance by stitches or seam, and the alloy L-3140/2024 by resistance by stitches or stitching.

Aluminum and Magnesium Alloys

These alloys are within the L-33XX Group of the UNE and 5XXX within the AA nomenclature.

These are easy-to-use metals, and they are also resistant to corrosion. But instead, they are not the strongest metals mechanically.

Also, special care must be taken, and temperatures too low should be avoided, as it can be dangerous.

There are some bonuses and some non-bonus alloys, and many can be welded, either by MIG / TIG or by resistance by stitches or by sewing.

These weldable alloys are the following: L-3360 (UNE) / 5052 (AA), – / 5652, L-3321/5083, L-3322/5086, L-3390/5454

and – / 5456.

SUNGOLDPOWER MIG 150A Welder Flux Core Wire Automatic Feed Welding AC Welder Gasless Machine Free Mask NO Gas

Lincoln Electric Weld Pak 140 HD Wire-Feed Welder K2514-1

Aluminum, Magnesium, and Silicon Alloys

Aluminum, Magnesium, and silicon alloys are part of the UNE Group L-34XX and 6XXX regarding the Aluminium Association.

They are solid and versatile alloys and stand out because they can be treated with heat.

This is because of the proportion they contain Silicon and Magnesium.

These alloys are bondable, but most can be welded by MIG / TIG, point resistance, seam, or solid welding.

Some of them are also by gentle welding. Here are the weldable alloys: L-3420/6061, L-3441/6063, and finally, L-3431/6101 and L-3451/6351, which can be welded by smooth welding.

Aluminum and Silicon Alloys

These Aluminium and silicon alloys are Group L-35XX and 4XXX in the AA.

Silicon contains the melting point of Aluminium to be significantly reduced. Therefore, it is not uncommon to find welding electrodes of this Group.

However, there are bonus and non-bonus alloys, and welding by typical processes is not recommended for alloys of this type.

Various alloys

In Group L-36XX, belonging to the UNE, what would be the terminology 8XXX of the AA? Since they are different alloys, you cannot accurately describe them.

Aluminum and Zinc Alloys

The Aluminium and Zinc alloys constitute the L-37XX Group and the 7XXX of the UNE and AA, respectively.

These alloys have very high resistance and are also widely used in aeronautics. In addition to Zinc, they usually contain some magnesium, which means they can be heat treated.

They are bonus alloys, and although the vast majority cannot be welded, some alloys are suitable for welding by MIG / TIG processes and spot welding or sewings, such as L-3741/7005 and L-3731/7039. And the L-3710/7075 alloy can be spot welded or sewn.

Aluminum and Manganese Alloys

The L-38XX Group of the UNE and the 3XXX of the AA name the Aluminium and Manganese alloys. They usually have about 1.5% manganese.

The most significant advantage is that they are straightforward to work with. Although they cannot be treated with heat, this alloy is a good option to enter the world of Aluminium and Aluminium alloy welding.

Aluminum and manganese alloys are non-bondable; two alloys stand out for their weldability; L-3810/3003 and L-3820/3004.

The first can be welded with TIG / MIG and by resistance by a point or seam, and the second, in addition to these processes, can also be welded by strong welding and smooth welding.

Aluminum and Tin Alloys

These alloys do not have a vocabulary in the AA but are from the L-39XX Group of the UNE.

Recommendations to start welding

Now that you know a little more about aluminum and its characteristics and weldability, we will tell you the steps you must follow to start welding finally.

Clean from aluminum

To weld without problems, the Aluminium parts have to be extremely clean.

Aluminum usually forms a thin layer of aluminum oxide, which melts at a much higher temperature than Aluminium.

This is a danger since there is a little rust. It can generate inclusions of rust in the weld, reducing the resistance of the weld.

The simplest way to perform this cleaning is usually mechanical, with a wire brush. Always use clean brushes or brushes used only to clean Aluminium.

The brushes used with other metals can leave traces of those metals that can affect the weld’s quality.

Another thing to remember is to brush gently because if you do it sharply, you can embed the oxides more in base Aluminium.

Select the appropriate input material for Aluminium

Both rods and coated wires and electrodes can be used as filler metal for Aluminium welding:

Coated electrodes for welding Aluminium

Coated electrodes are used with direct reverse polarity (DC +) current. You must be very careful with moisture, and better if you dry them before using them for welding. Otherwise, they can produce spores.

It would be best if you chose the most similar to your base Aluminium, these being the most common electrodes:

| Electrode designation | Electrode composition |

| E 1100 | Pure Aluminium |

| E 3003 | Aluminum – 1% Manganese |

| E 4043 | Aluminum – 5.2% Silicon (Alloy for the manufacture of electrodes and welding rods) |

Wires and rods for welding Aluminium

In the same way, if you choose a rod, select an Aluminium filling material of a melting temperature similar to that of the base Aluminium.

Remember that the rods have to be clean to get a good weld.

The most common is usually the 4043 and 5356 alloy rods. You can opt for either if you don’t have it very clear.

| Rod Designation | Chemical composition of the rod |

| ER 1100 | Pure Aluminium |

| ER 2319 | Aluminum – 6% Copper – 0.3% Manganese (It is a variant of 2219) |

| ER 4043 | Aluminum – 5.2% Silicon (Alloy intended for electrode and rod manufacturing) |

| ER 4047 | Aluminum – 12% Silicon |

| ER 4145 | Aluminum – 10% Silicon – 4% Copper |

| ER 5183 | Aluminum – 4.5% Magnesium – 0.65% Manganese (It is a 5083 variant) |

| ER 5356 | Aluminum – 5% Magnesium – 0.3% (Manganese + Chrome) |

| ER 5554 | Aluminum – 2.9% Magnesium – 0.65% Manganese |

| ER 5556 | Aluminum – 5% Magnesium – 0.7% Manganese |

| ER 5654 | Aluminum – 3.5% Magnesium |

Use a fill rod of the same size as the tungsten electrode.

Hold the workpieces

Before welding, you must ensure that the pieces you have to weld will not move.

To do this, you can use clamps and thus securely attach them to your worktable.

Never forget about protection.

As mentioned in our articles, protection is vital for welding, so the more you protect yourself, the safer you will work.

You don’t need the complete equipment, but you should have gloves and a darkening helmet.

Also recommended are the welding apron, the respiratory mask, and safety shoes.

Preheat the Aluminium

Preheating, in general, is usually not necessary.

But the pieces of great thickness are an exception since, in this case, the preheating can reduce the thermal contribution to obtain suitable fusion.

Preheating is usually usual when using the TIG process but not when using MIG welding.

Read Next – Welding types: TIG vs. MIG vs. Electrode vs. Arc

Weld Aluminium with TIG

TIG welding is the most commonly used process for welding Aluminium.

And it is that a welding machine that can control the current is handy to prevent the Aluminium part from overheating and causing burns.

This is because Aluminium needs a lot of heat to reach its temperature, but it can keep a long time once it goes.

Also, TIG welding can be used in thin and thicker Aluminium.

Before starting with all the steps, I leave you a great video about TIG welding for Aluminium:

For TIG welding of Aluminium, a shielding gas is used. Argon is usually used due to its good cleaning action and penetration profile, and 3% helium can also be added for more excellent arc stability.

But if what will be welded is an Aluminium and magnesium alloy, a mixture of argon with helium (a maximum of 75% helium) is recommended to minimize the creation of magnesium oxide.

SUNGOLDPOWER MIG 150A Welder Flux Core Wire Automatic Feed Welding AC Welder Gasless Machine Free Mask NO Gas

Lincoln Electric Weld Pak 140 HD Wire-Feed Welder K2514-1

TIG welding for Aluminium with the direct-current negative electrode (CC-)

Steps to follow to weld Aluminium with TIG

- Set the correct amperage for your project. You must calculate 1 amp for every 0.025 mm thick Aluminium. Do the approximate calculation, and if in doubt, raise a little more since you can adjust it with the pedal.

- Prepare the tools to work. You have to extend the tungsten electrode to a diameter similar to the nozzle you will use. Support the electrode tip on the metal piece, and keep it about 3 mm.

- Use the pedal and the torch button to adjust. The torch usually has control to create the electric arc. So you will need to press it to start welding. If, on the contrary, the torch does not have any buttons, you have to create the arc with the pedal. It would be best if you pressed it halfway. You probably have to raise the amperage if you can’t generate the angle.

- Create the welding puddle. You must meet the material to create the pool of solder necessary to fill the joint. Go forward through the entire union until you finish welding everything. The disadvantage is that the Aluminium will heat up over time, so you should reduce the amperage not to burn the piece as you go along.

- Please wait for it to cool. Once you have done the joint welding, you must wait for everything to cool.

Weld Aluminium with MIG

MIG welding can also be used to weld Aluminium.

It is the most suitable process for thin Aluminium sheets due to the heat they need.

I leave a video as a warm-up:

The wire feeding system can be a drag, push, or drag-push.

This will depend on the thickness and hardness of the alloy. Also, constant voltage power sources with regular speed feeders are used for small-diameter wires.

In contrast, constant-intensity power sources and variable-speed feeders are used for large-diameter wires.

Argon is a protective gas since pure argon is the best gas for aluminum MIG welding.

As for the transfer gases, different types of transfer can be used, although the transfer typically used in MIG welding of Aluminium is usually the transfer of spray or spray.

BOSTITCH S16D131GAL-FH 28 Degree 3-1/2-Inch by .131-Inch Wire Weld Galvanized Framing Nails (2,000 per Box)

Forney Easy Weld 261, 140 FC-i MIG Welder, 120V, Green

1 used from $320.74

The technique for welding Aluminium with MIG

The forward welding technique tilts the gun about 7º to 12º toward the welding direction.

To turn off the arc, the speed is increased until the electrode is separated from the workpiece, or the other option is to change the welding direction and cut the angle on the welding bead.

Appendices can also be used to extinguish the arc over them. Alloys that are bondable are welded with straight strands.

Finally, you should know that MIG welding of Aluminium has some disadvantages, such as imperfections that can be created, such as melting faults, cracks in the crater, porosity, and inclusion of oxides.

Weld Aluminium by an electric arc with coated electrode

Aluminum can also be welded by an electric arc, although it is not highly recommended because the cord obtained is usually not homogeneous.

But if you need to perform welding where this is not a problem, this type of welding may be an option.

Remember that the electrodes must be completely dry and clean to use without problems, so it is advisable to dry them.

Also, it would be best if you preheated the pieces in case they are complicated and of great thickness.

And it is that a thickness of 3 mm is minimally recommended to use in this welding process on Aluminium.

With more than 6 mm, a V chamfer from 60º to 90º must be made, and for large thicknesses, the U preparations are recommended.

After welding, the slag must be removed with a brush, pickaxe, and with the help of hot water.

And it is that the slag favors the corrosion of Aluminium.

Weld Aluminium by Oxigas

Oxigas can weld aluminum alloys and the Aluminium itself, but it is recommended to use this process only for minor repairs and welding.

Above all, you can use it if the thicknesses of your pieces range between 0.7 and 25 mm.

This process has the advantage of being straightforward but also has a few disadvantages.

And, among other things, you have to use filler material. The process is prolonged, deformations occur, and it deforms very easily.

The fuel used in acetylene with a neutral flame, although sometimes aflame with enough acetylene, can reduce the formation of oxides.

Single V chamfers are made if the pieces are thicker than 5 mm. They can be made with amounts up to 12 mm.

B backing plates or overlapping joints are not recommended since the flux can remain and cause corrosion in the base metal.

If the thickness of the piece is large, a preheat should be performed before welding. To do this, you have to move the flame circularly and heat the edges of the joint until the melting bath is formed.

The contribution metal rod will be placed, and the joint will continue advancing until all the material is melted.

After welding, all remaining flux residue must be removed. To do this, you have to bathe the pieces of water with small amounts of nitric or sulfuric acid and then wash them with water. Large pieces can also be steam cleaned.

Weld Aluminium by Strong Welding

Some alloys can be welded by brazing, although most alloys cannot be welded by this method.

What you have to look to know if you can or not is the melting temperature of the metal.

And is that many times the melting temperatures of the base metal and the contribution metal are usually very similar, as is the case with Aluminium and copper alloys, and some Aluminium and zinc alloys, such as 7055, 7178, and 7001 (AA)

Aluminum and silicon alloys are typically used as filler metals. To select the correct metal, you must ensure that the melting temperature of the filler material is lower than the base metal.

And more if a blowtorch does welding.

The paste is applied in the form of a paste, and it is recommended not to use too much to avoid problems with corrosion.

After welding, remove the flux with hot water and a fiber brush, never a wire brush.

Weld Aluminium by Soft Welding

To perform smooth welding, a flux is needed to remove the oxide layer and to avoid contact with air, among other things.

You must permanently eliminate waste from this flux, as they absorb moisture.

They are removed quite quickly with hot water.

The materials usually used in the contribution metals are tin, Zinc, lead, and cadmium.

But the best mechanical properties are the high-temperature zinc filler metals since they also have excellent corrosion behavior.

BOSTITCH S16D131GAL-FH 28 Degree 3-1/2-Inch by .131-Inch Wire Weld Galvanized Framing Nails (2,000 per Box)

Forney Easy Weld 261, 140 FC-i MIG Welder, 120V, Green

1 used from $320.74

How to “Weld” Aluminum for Beginners

People also ask

What kind of welder do you need to weld aluminum?

MIG welding is best for thinner aluminum sheet gauges because of the heat needed. When choosing a shielding gas, one hundred percent argon is best for MIG welding aluminum.

To create a quality weld, the welder must choose a welding wire or rod with an alloy similar to the workpieces.

Is it difficult to weld aluminum?

Aluminum doesn’t act the way other metals do during welding, so it can be challenging to determine weld progress and quality.

BAluminum is rugged to weld because it is a soft, susceptible metal insulated by a more rigid oxidized layer.

Can you stick weld aluminum?

Can I weld aluminum with a MIG welder?

Aluminum is a tricky metal to weld with a MIG welder because it takes more heat than mild steel (Usually in the range of 21 to 24 volts).

When MIG welding mild steel, you can and should move the MIG gun slowly enough to get deep penetration.

Can you use a wire feed welder to weld aluminum?

BOSTITCH S16D131GAL-FH 28 Degree 3-1/2-Inch by .131-Inch Wire Weld Galvanized Framing Nails (2,000 per Box)

Forney Easy Weld 261, 140 FC-i MIG Welder, 120V, Green

1 used from $320.74

SUNGOLDPOWER MIG 150A Welder Flux Core Wire Automatic Feed Welding AC Welder Gasless Machine Free Mask NO Gas

Lincoln Electric Weld Pak 140 HD Wire-Feed Welder K2514-1

MIG Welding Wire, L-56.030, Spool

$76.59 in stock

YESWELDER ARC Welder 205Amp Digital Inverter IGBT Stick MMA Welder,110/220V Dual Voltage Hot Start Portable Welding Machine

Welder Arc Welder 160Amp Stick MMA Welding Machine IGBT Smart VRD Hot Start fits Below 3.2mm Welding rods (yellow 110/220V)

Goplus 250 AMP MMA Welder ARC Welding Machine 110V/ 220V Soldering Accessories Tools

MIG155GSV 155 AMP INVERTER MIG/STICK ARC WELDER WITH DUAL VOLTAGE 220V/110V welding machine

2020 Weldpro 200 Amp Inverter Multi Process Welder with Dual Voltage 220V/110V Mig/Tig/Arc Stick 3 in 1 welder/welding machine

Shikha ARC Welding Machine Dual 110V/220V,DC Inverter Welder 20-250Amp IGBT Digital Display LCD with Welder Inverter Welding Machine Kits

$109.99 in stock

Amico Professional Welding Machine, 200 Amp Stick Arc DC Welder, 80% Duty Cycle, 100~250V Wide Voltage

Super Deal PRO Commercial MIG 130 AC Flux Core Wire Automatic Feed Welder Welding Machine w/Free Mask 110V

Reboot ARC Welder Dual Voltage ARC145 MINI Stick ARC Welding Machine 110V/220V High Frequency Duty Cycle Inverter 1/16~1/8'' MMA Stick Welding Machine

VIVOHOME Portable Flux Core Wire No Gas MIG 130 Welder Machine 110V Black

Goplus MIG 130 Welder Flux Core Wire Automatic Feed Welding Machine

Dewalt Premium Leather Welding Gloves, Fire/Heat Resistant, Gauntlet-Style Cuff, Elastic Wrist, Medium

Miller Electric MIG Welding Gloves 271888 - Size Large

Tillman 1414 Top Grain/Split Cowhide Drivers Gloves, Medium

$16.50 in stock

Revco REVCO - T50 - Large"The Ultimate Tig Welding Glove", Large

$30.15 in stock

Welding Gloves, 3D, Wing, 13In, Blueblack, PR

Tillman Medium 14" Gold and Pearl Top Grain Split Back Cowhide Fleece Lined MIG Welders Gloves with 4" Cuff and Kevlar Thread Locking Stitch (Carded)

$27.90 in stock

Lincoln Electric Premium TIG Welding Gloves | Top Grain Leather | High Dexterity | Medium | K2983-M

Lincoln Electric KH643 Leather Welding Gloves, One Size, Red

$23.65 in stock

Miller Electric Mens MIG Welding Gloves, 271889, Size XLarge

QeeLink Leather Welding Gloves - Heat & Flame Resistant For Welders/Fireplace/BBQ

Q: What is aluminum welding?

A: Aluminum welding is the process of joining two or more aluminum pieces together using heat to melt the aluminum and then allowing it to cool and solidify, creating a solid bond.

Q: What are the benefits of using aluminum for welding?

A: Aluminum has several benefits for welding, including its high strength-to-weight ratio, excellent corrosion resistance, and good thermal conductivity. It is also lightweight and highly durable, making it a popular choice for various applications.

Q: What is a welder?

A: A welder is a person who operates welding equipment to join or repair metal parts. They are skilled in using various welding techniques and equipment, such as MIG or TIG welders.

Q: What is MIG welding?

A: MIG welding, also known as metal inert gas welding, is a welding process that uses a continuously fed wire electrode and a shielding gas to melt and join metal pieces together. It is commonly used for aluminum welding.

Q: What is TIG welding?

A: TIG welding, or tungsten inert gas welding, is a welding process that uses a non-consumable tungsten electrode to produce the weld. It is a precise and versatile welding technique commonly used for aluminum welding.

Q: Can I weld aluminum without a MIG welder?

A: It is possible to weld aluminum without a MIG welder. However, MIG welding is generally preferred for aluminum welding due to its ease of use and efficiency.

Q: How can I clean the aluminum before welding?

A: To clean the aluminum before welding, you can use a wire brush or a specialized aluminum cleaner to remove any dirt, grease, or oxide formation on the surface. This will help ensure a clean and contaminant-free weld.

Q: What is the process of MIG welding aluminum?

A: MIG welding aluminum involves feeding a spool of aluminum wire through a MIG gun connected to an appropriate power source. A shielding gas, such as argon, protects the weld pool. The aluminum filler metal is melted by the electric arc and deposited onto the workpiece, creating a solid weld.

Q: How can I weld aluminum without contaminating it?

A: To prevent contamination when welding aluminum, cleaning the aluminum surface thoroughly and using clean welding equipment is essential. It is also recommended to use a proper shielding gas and to avoid using steel wire or other materials that can contaminate the weld.

Q: Can I weld thicker aluminum with MIG welding?

A: MIG welding can be used to weld thicker aluminum, but it may require preheating the aluminum or using multiple passes to achieve a strong weld. The specific welding parameters will depend on the thickness and type of aluminum being welded.